58 3062555_201804

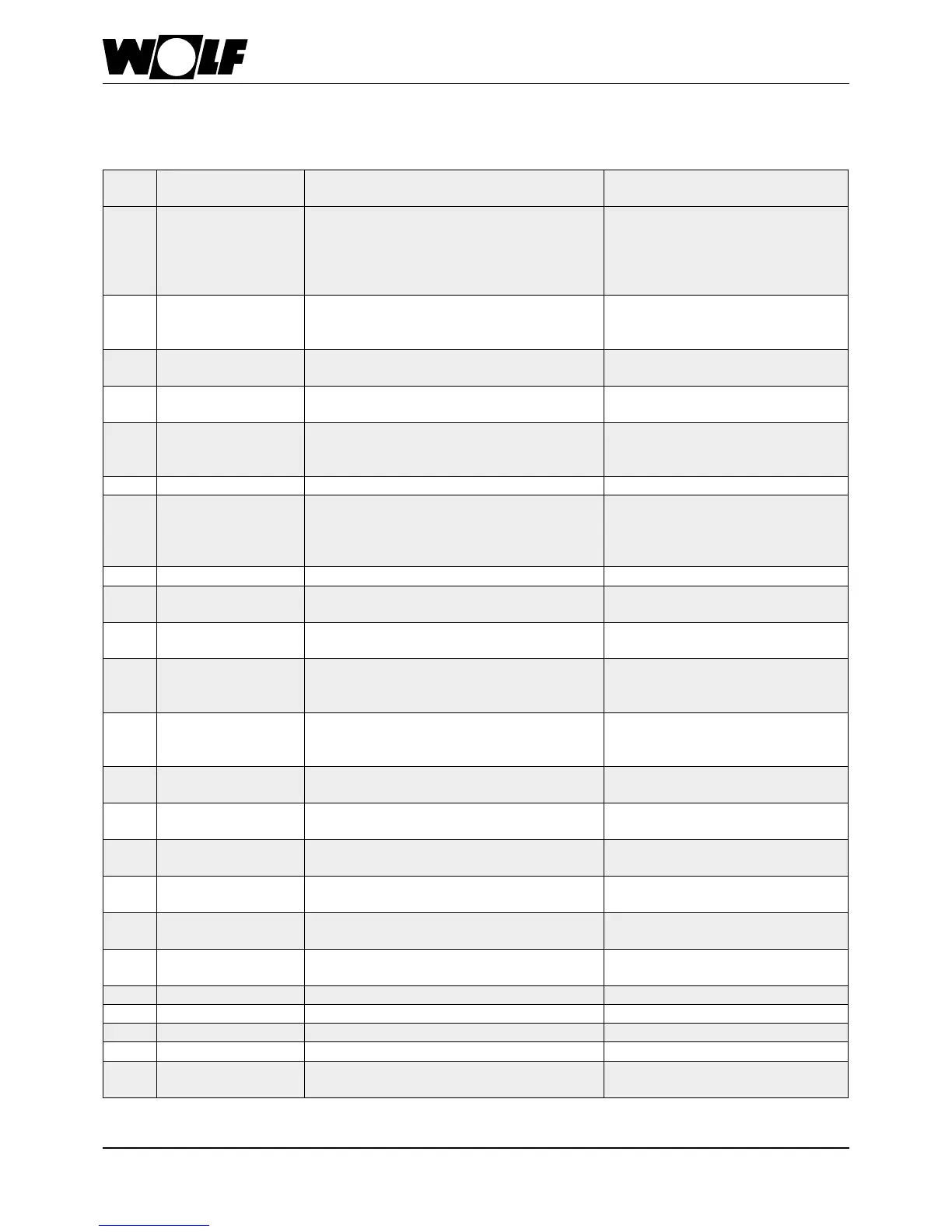

31.Troubleshooting

Any faults will be displayed as fault codes by Wolf controllers with eBUS capability. To these faults, cause and remedy may be

allocated using the following table. This table is designed to allow your local heating contractor to trace the fault more easily.

Fault

code

Fault Cause Remedy

1 TBV excess temperature

combustion chamber

cover STB

water pressure too low

Theowtemperaturehasexceededthelimitforthe

TBV shutdown temperature, or the heat exchanger is

extremely dirty, or the waterpressure switch switches off

atapressure<1.0bar

Check system pressure; check heating circuit

pump; vent the system; press reset; clean

the heat exchanger; check the TB combus-

tion chamber; increase system pressure;

checkdirtlter

4 Noame

established

Noamebuildsduringburnerstart. Check gas supply line, opening gas tap

if necessary; check ignition electrode and

ignition cable press reset button

5 Flame failure

during operation

Flamefailurewithin15sfollowingamedetection Check CO2 values, check ionisation elec-

trode and cable press reset button

6 DHWexcesstemperature Theow/returntemperaturehasexceededthelimitof

the TW shutdown temperature

Check system pressure. Vent the system.

Set the pump to stage 2 or 3.

7 TBA excess temperature

Excess pressure in

theuesystem

Theuegastemperaturehasexceededthelimitfor

theTBAshutdowntemperatureortheuesystemis

blocked, or the ventilation air is blocked.

Clean the heat exchanger

Checktheuesystem

Check the ventilation air

11 Flame pretence Aameisdetectedbeforetheburnerstarts Press reset button.

12 Faultyowsensor

gas pressure too low.

Thesensorfortheowtemperatureorthecableis

faulty,orthegaspressure<thantheselectedvalueat

the gas governor (only displayed after 15 min)

Check the cable

Checkowsensor

Check gas pressure

Check gas governor (accessory)

14 Cylinder sensor faulty DHWtemperaturesensororleadfaulty Check sensor and lead

15 Outside temperature

sensor faulty

The outside temperature sensor or cable is faulty Check cable

Check outside temperature sensor

16 Return sensor faulty The return temperature sensor or lead is faulty Check cable

Check return sensor

20 Fault, gas valve "1" Aameisrecognisedfor15secondsafterburner

operation, even though gas valve 1 has received a

shutdown command

Replace gas combination valve

21 Fault, gas valve "2" Aameisrecognisedfor15secondsafterburner

operation, even though gas valve 2 has received a

shutdown command

Replace gas combination valve

24 Gas fan fault The gas fan does not reach the required pre-purging

speed

Check the supply cable to the gas fan and

check the gas fan. Press reset button.

25 Gas fan fault The gas fan does not reach the ignition speed Check the supply cable to the gas fan and

check the gas fan. Press reset button.

26 Gas fan fault The gas fan does not stop. Check the supply cable to the gas fan and

check the gas fan. Press reset button.

30 CRC fault,

gas condensing boiler

The EEPROM record "Gas condensing boiler" is invalid Switch the power supply off and on. If unsuc-

cessful replace the controller PCB.

31 CRC error, burner The EEPROM record "Burner" is invalid. Switch the power supply off and on. If unsuc-

cessful replace the controller PCB.

32 Fault in 24 V AC

supply

24 V AC supply outside the permissible range

(e.g. short circuit)

Check the gas fan.

33 CRC error, default values The EEPROM record "Master reset" is invalid Replace control unit PCB

34 CRC fault, BCC Boiler coding card fault Replace boiler coding card

35 BCC missing Boiler coding card was removed Fit the correct boiler coding card

36 CRC fault, BCC Boiler coding card fault Replace boiler coding card

37 Incorrect BCC The boiler coding card is incompatible with the control

unit PCB

Fit the correct boiler coding card

Loading...

Loading...