20 3062555_201804

10.Installation

Gasconnection

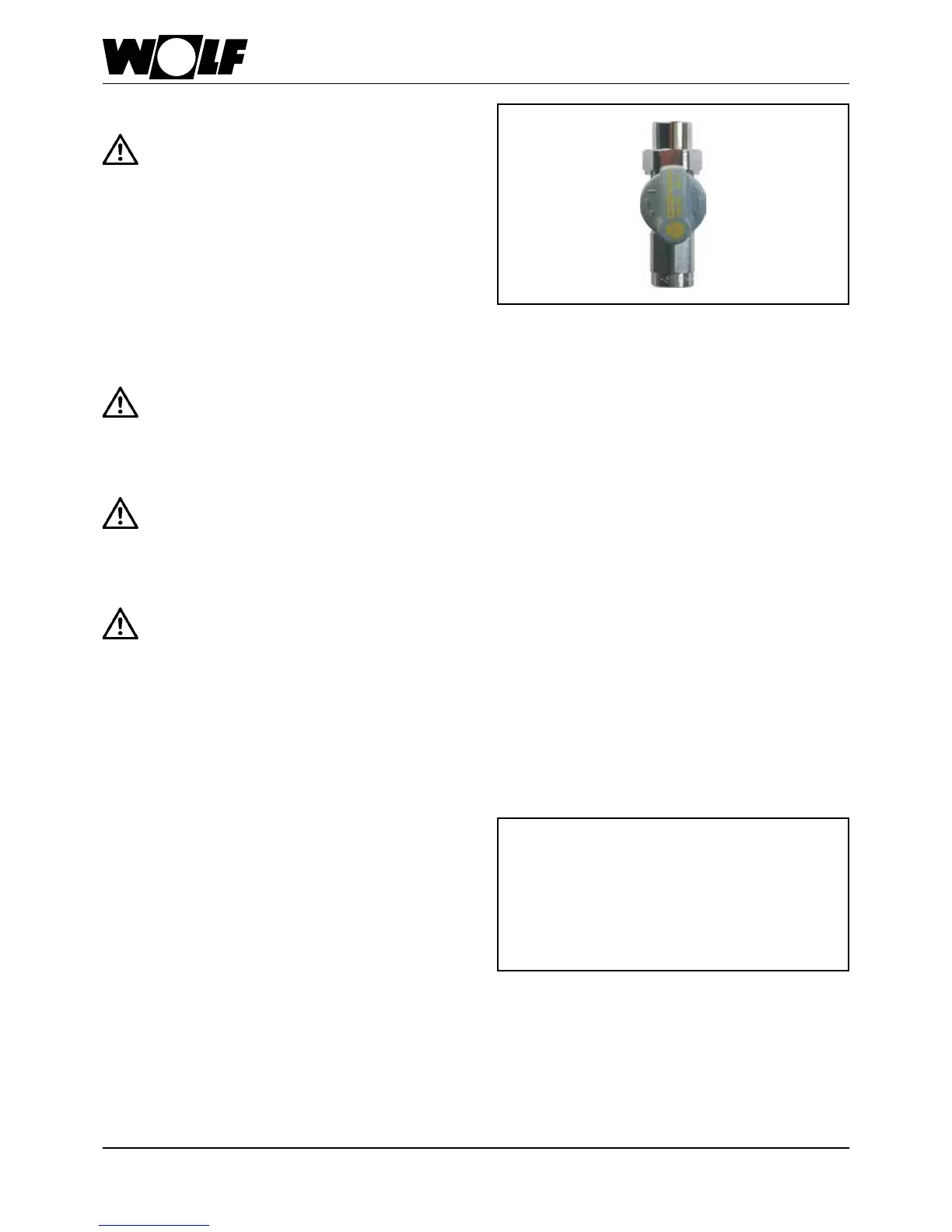

Fig.: Straight-through gas ball valve (accessory)

Onlyalicensedgasttermayroutethegaspipe

andmakethegasconnections.Closethegas

ballvalveonthecondensingboilertopressure

testthegaspipe.

Removeallresiduesfromtheheatingpipework

andthegaspipepriortoconnectingthecon-

densingboiler,particularlyinoldersystems.

Priortocommissioning,testallgaspipesand

connectionsforleaksaccordingtoTRGI.Only

foaming leak detection sprays which are ap-

provedbytheDVGWshouldbeused.

Inappropriate installation or using unsuitable

components or assemblies may lead to gas

escaping,whichresultsinariskofpoisoning

andexplosion.

Install a gas ball valve with fire protection

in the gas supply line upstreamof the Wolf

condensingboiler.Otherwiseexplosionsmay

occurifthereisare.Sizethegassupplypipe

in accordance with DVGW-TRGIregulations

[Germany].

Gasttingsontheappliancemayonlybepres-

sure-testedtoamaximumof150mbar.Higher

pressuremaydamagethegastrain,resultingin

ariskofexplosion,asphyxiationorpoisoning.

Closethegasballvalveonthegascondensing

centretopressuretestthegaspipe.

Mountthegasballvalveinaneasilyaccessible

place.

- Prior to installation, ensure that the boiler corresponds to the

local gas type. The factory settings for the particular type of

gas can be obtained from the following table.

Table: Factory setting according to gas type

1)

Not applicable for Austria/Switzerland

2)

Does not apply to Switzerland

NaturalgasE/H:

Ws=11.4-15.2kWh/m

3

=40.9-54.7MJ/m

3

NaturalgasLL:

1)

Ws= 9.5-12.1kWh/m

3

=34.1-43.6MJ/m

3

LPG P:

2)

Ws=20.2-21.3kWh/m

3

=72.9-76.8MJ/m

3

Loading...

Loading...