393062555_201804

B)CO

2

settingforlowerload(softstart)

- Remove the protective screw over the zero point adjusting

screw with a Torx screwdriver.

- Restart the condensing boiler by pressing the "Reset button".

- Check and correct (if required) the CO

2

content approx. 20 s

after the burner start with the CO

2

tester,byneadjusting

the zero point adjusting screw with Torx in accordance with

the table. Make this adjustment within 180 s of the burner

start. If necessary, repeat the start phase for the setting

procedure by pressing the reset button.

- Duringthisadjustment,theremustbenoDHWoperation!

- Retighten the protective screw.

23. CO

2

adjustments

- Clockwiserotation–higherCO

2

contentincreased!

- Anti-clockwiserotation–lowerCO

2

contentreduced!

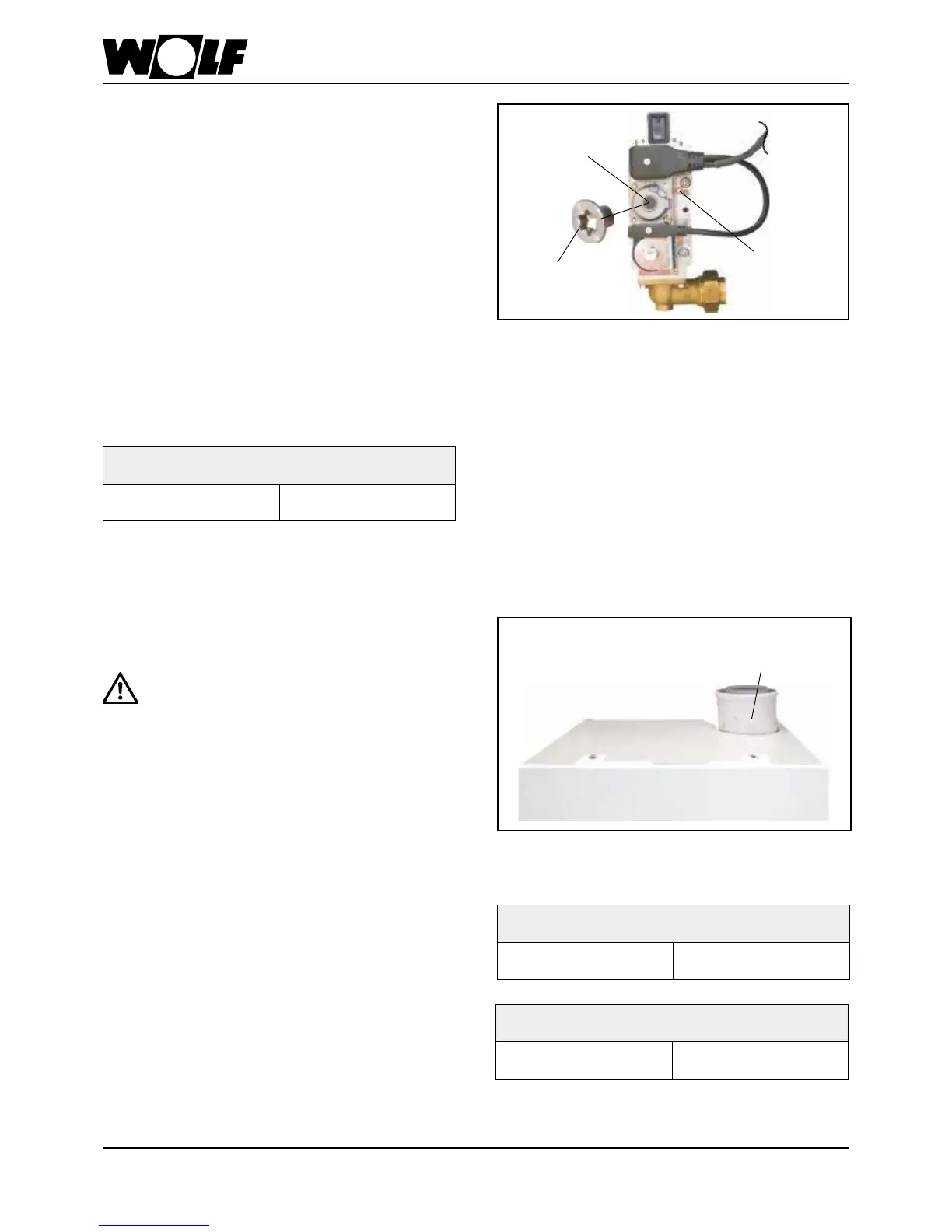

Zero point

screw

Fig.: Gas combination valve

Protective

screw

Gas throughput

adjusting screw

D)Completingtheadjustments

- Shut down the boiler and close the test ports and hose

connection nipples again. Check the gas supply line and

hydraulics for tightness.

C)CheckingtheCO

2

setting

- Aftercompletingthework,retthecasingcoverandcheck

the CO

2

values with the appliance closed.

Observe the CO emissions whilst making

CO

2

settings. The gas combination valve is

incorrectly adjusted if the CO value is > 300

ppmwhentheCO

2

valueiscorrect.Take the

followingsteps:

- Fully insert the zero point adjusting screw

- Open the zero point adjusting screw 1½ revolutions

- Repeat the adjusting process from section A)

- The condensing boiler is correctly adjusted if the CO

2

values

correspond to those in the adjacent table.

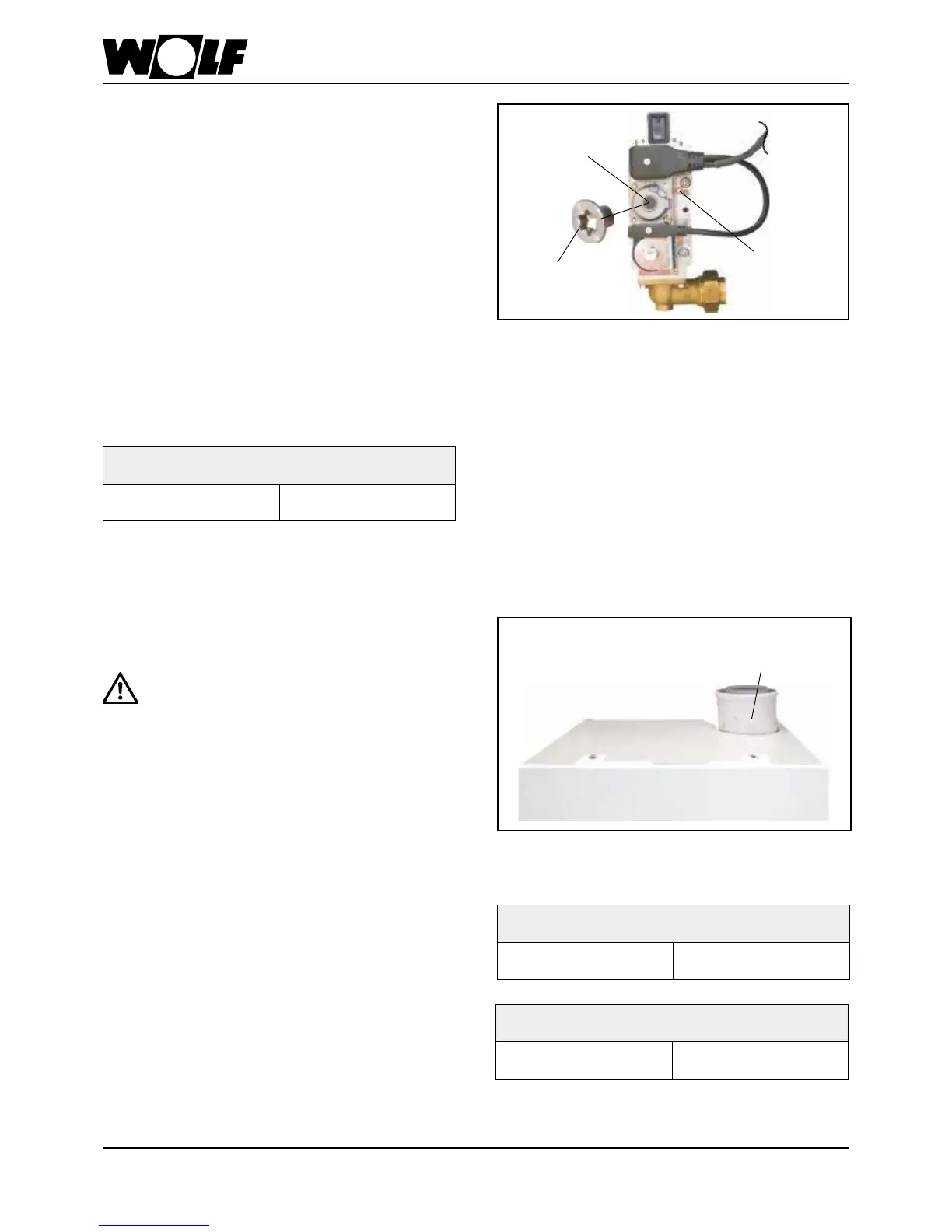

Fig.: Emission test with closed appliance

Test port

"Flue gas"

Applianceopen

at lower load

NaturalgasE/H/LL

8.5% ± 0.2%

LNG P

9.7% ± 0.2%

Applianceclosed

at upper load

NaturalgasE/H/LL

8.8% ± 0.5%

LNG P

10.3% ± 0.5%

Applianceclosed

at lower load

NaturalgasE/H/LL

8.7% ± 0.5%

LNG P

9.9% ± 0.5%

Loading...

Loading...