Sawmill Operation

4

Sawmill Operation LX25 8/25/21 4-1

SECTION 4 SAWMILL OPERATION

If a blade or drive belt breaks during operation, wait until all moving parts stop completely.

Ensure ground is firm and level.

Clear the area.

Inspect the site for debris or uneven surfaces that may become a trip hazard.

Clear out all non-essential personnel before starting.

Ensure that the operator is wearing personal protection equipment and proper work clothing.

Check the engine oil level. (See the Engine Manual.)

Optimal operating temperature range is 5°F (-15°C) to 105°F (40°C).

Ensure all guards and covers are in place and secured/closed.

Ensure all personal protection equipment is used.

Gas mills

Do not operate in enclose areas.

Position operator upwind, away from sawdust and exhaust.

4.1 Sawmill adjustments

Tension the blade

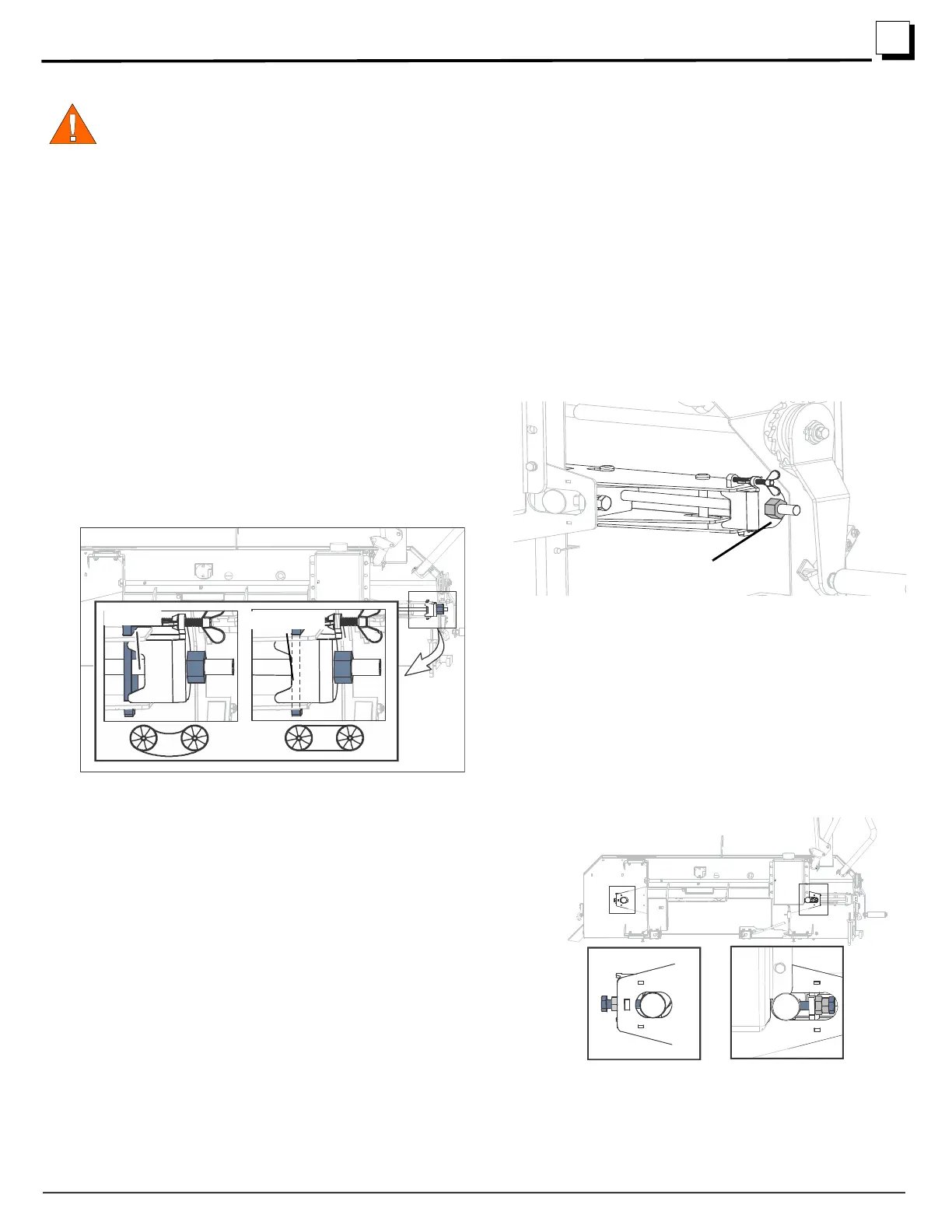

In the hardware box, there is a ratcheting wrench for setting the

wheels for proper tension.

(See FIG. 4-1 .)

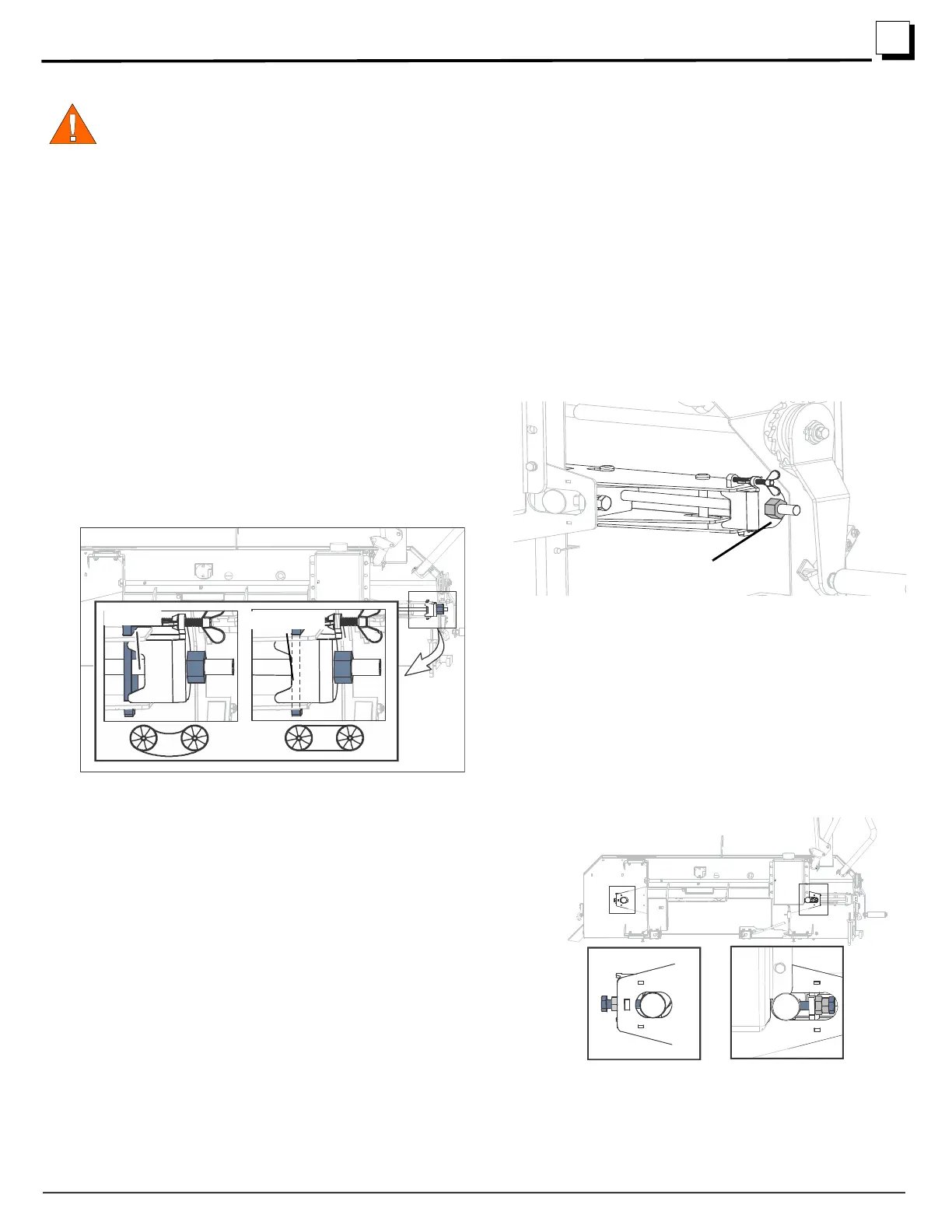

Turn the blade tensioning nut until there is no gap between the

back of tensioning plate and the housing. (SEE FIG. 4-2 .)

Blade tracking

When tensioned properly, check the tracking of the blade by spinning the

wheel a few times by hand.

Ensure the back of the blade remains approximately flush to 1/8 inch of

overhang at the rear edge of the wheels.

On the back of each side of the sawhead, adjustment bolts are available for

tracking the blade. (See FIG. 4-3 .)

Loosen the set nuts on the adjustment bolt and move the wheel until it is

properly aligned. The blade should track straight without moving in or out

from the final setting, and the blade remains flush to 1/8" overhang to the

rear edge of the wheel.

(See FIG. 4-4 .)

When the blade tracks straight, tighten the rear set nuts.

WARNING!

Blade

tensioning

nut

FIG. 4-1

Gap

No gap

FIG. 4-2

FIG. 4-3

Loading...

Loading...