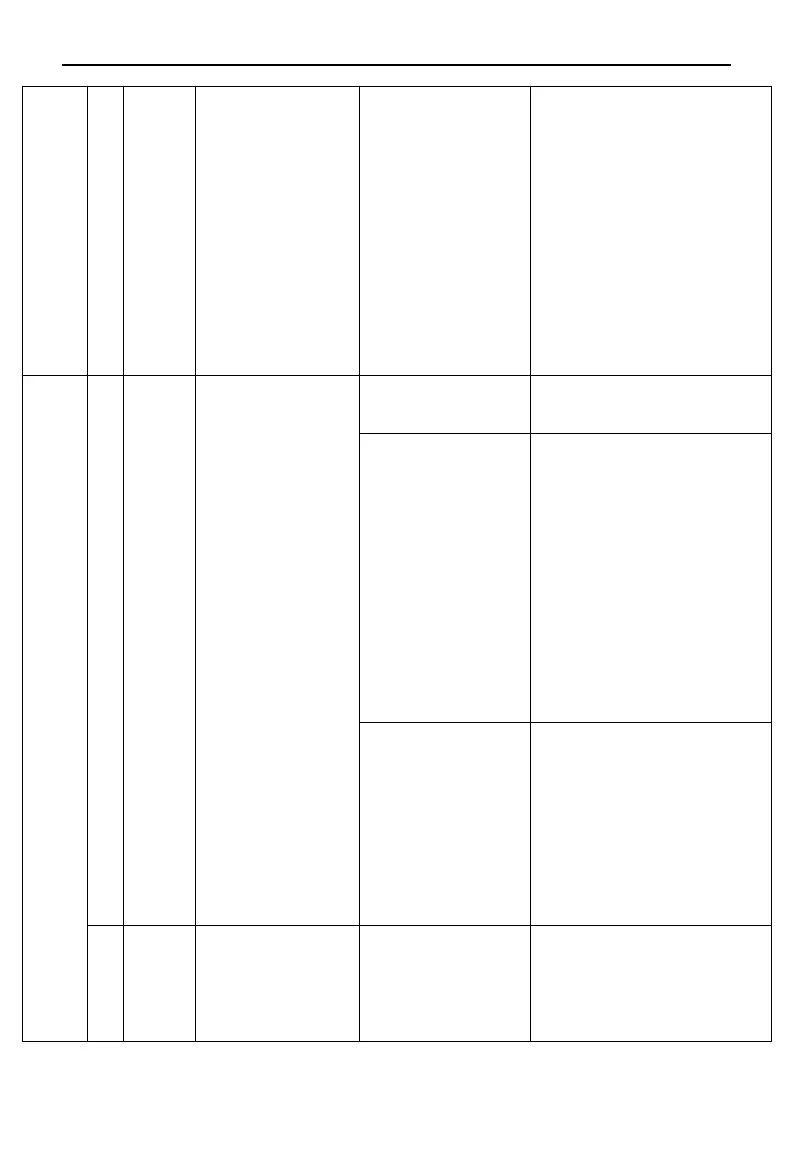

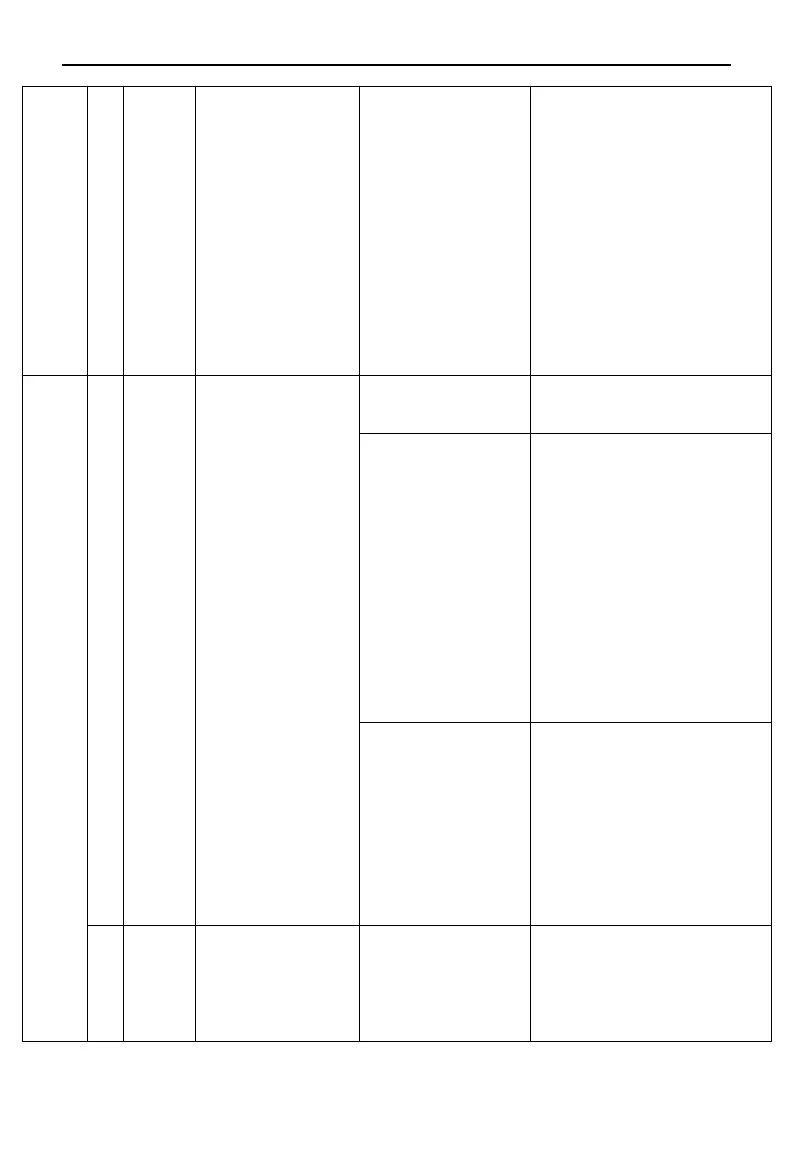

10% of the normal value. If the

power supply voltage is more than

220V+10% (380V+10%), check the

power supply voltage; if the power

supply voltage is normal, then in

servo BB state, monitor U0-05, the

voltage measured by the multimeter

* 1.414 < U0-05 (within 10V error),

then the servo driver is faulty and

needs to be sent back for repair.

22

0 E-220

Communication error

of absolute servo

encoder

Absolute value servo

encoder battery low

voltage alarm (can

shield this alarm)

Absolute value servo

encoder data access

alarm

Motor matching error

Check if the motor matches

correctly

Unconnected encoder

cable or poor contact

Disconnect the power supply of the

driver, check the connection of the

encoder cable, if there is cable

loosening, it is recommended to use

the multimeter to test the

conduction condition; after

eliminating errors, power on again

Hot plugging is strictly prohibited,

and special cables are required for

tank chains.

Received encoder data

errors, and the number

of errors exceeds the

number of error retries

of encoder registers P0-

56

Encoder wire and strong power do

not have the same pipeline wiring;

install filter on servo driver power

input side; encoder wire sleeves

magnetic ring; shut down welding

machine type of equipment with

large interference

2 E-222 Absolute Servo

Encoder Value

Overflow

Communication error

Battery Voltage in

Battery Box of Encoder

cable is less than 2.75V

Please replace the battery while

keeping the power supply ON of the

servo driver in order to avoid the

error of encoder position

84

Loading...

Loading...