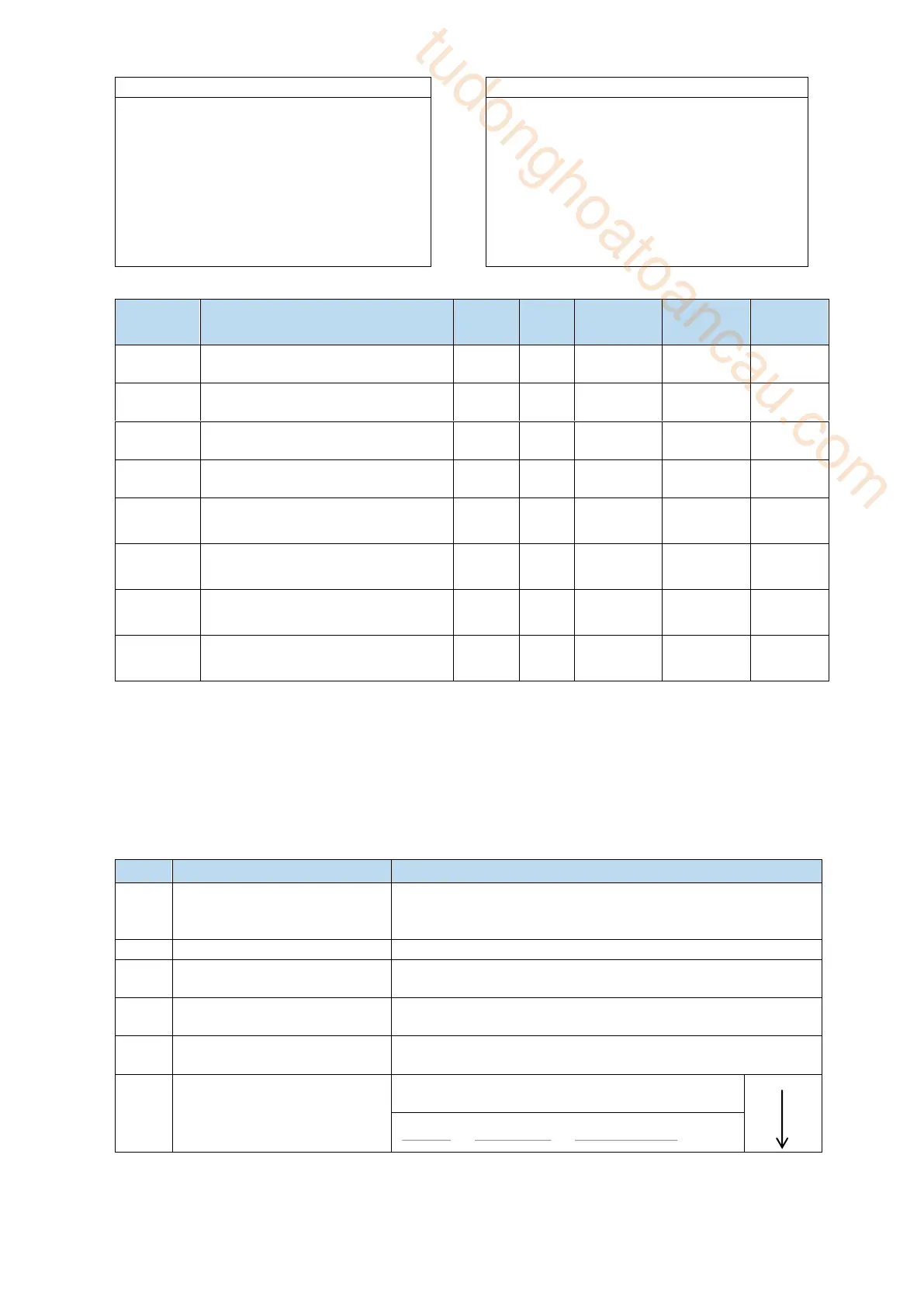

Do not change the electronic gear ratio

Change the electronic gear ratio

Without changing the ratio of the electronic

gear to the motor, the rotating cycle is

131072 pulses (P 0-11=0, P 0-12=0).

If the workpiece is moved 6 mm in one turn,

the number of pulses needed is 131072. If the

workpiece is moved 10 mm, it will need

10/6*131072=218453.333 pulses. When the

decimal number is omitted, the error will

occur.

By changing the electronic gear ratio, the

motor needs 6000 pulses to rotate one circle.

If the workpiece moves 6 mm in one turn, the

number of pulses needed is 6 000. If the

workpiece is moved 10 mm, it needs

10/6*6000 = 10000 pulses. When the pulse is

sent, the decimal number will not be produced

and the error will not be produced.

Pulse numbers per rotation *1

Pulse numbers per rotation *10000

Electronic gear ratio (numerator)

Electronic gear ratio (denominator)

Group 2 Electronic gear ratio

(numerator) low bit*1

Group 2 Electronic gear ratio

(numerator) high bit*10000

Group 2 Electronic gear ratio

(denominator) low bit*1

Group 2 Electronic gear ratio

(denominator) high bit*10000

Note:

(1) P0-11~P0-14 is all about the parameters of electronic gear ratio, P0-11, P0-12 is group 1, P0-13,

P0-14 is group 2, but the priority of P0-11 and P0-12 is higher than that of P0-13 and P0-14. Only

when P0-11 and P0-12 are set to 0, the ratio of electronic gear P0-13 and P0-14 will take effect.

(2) When P0-11, P0-12, P0-13 and P0-14 are all set to 0, P0-92, P0-93, P0-94 and P0-95 will take

effect.

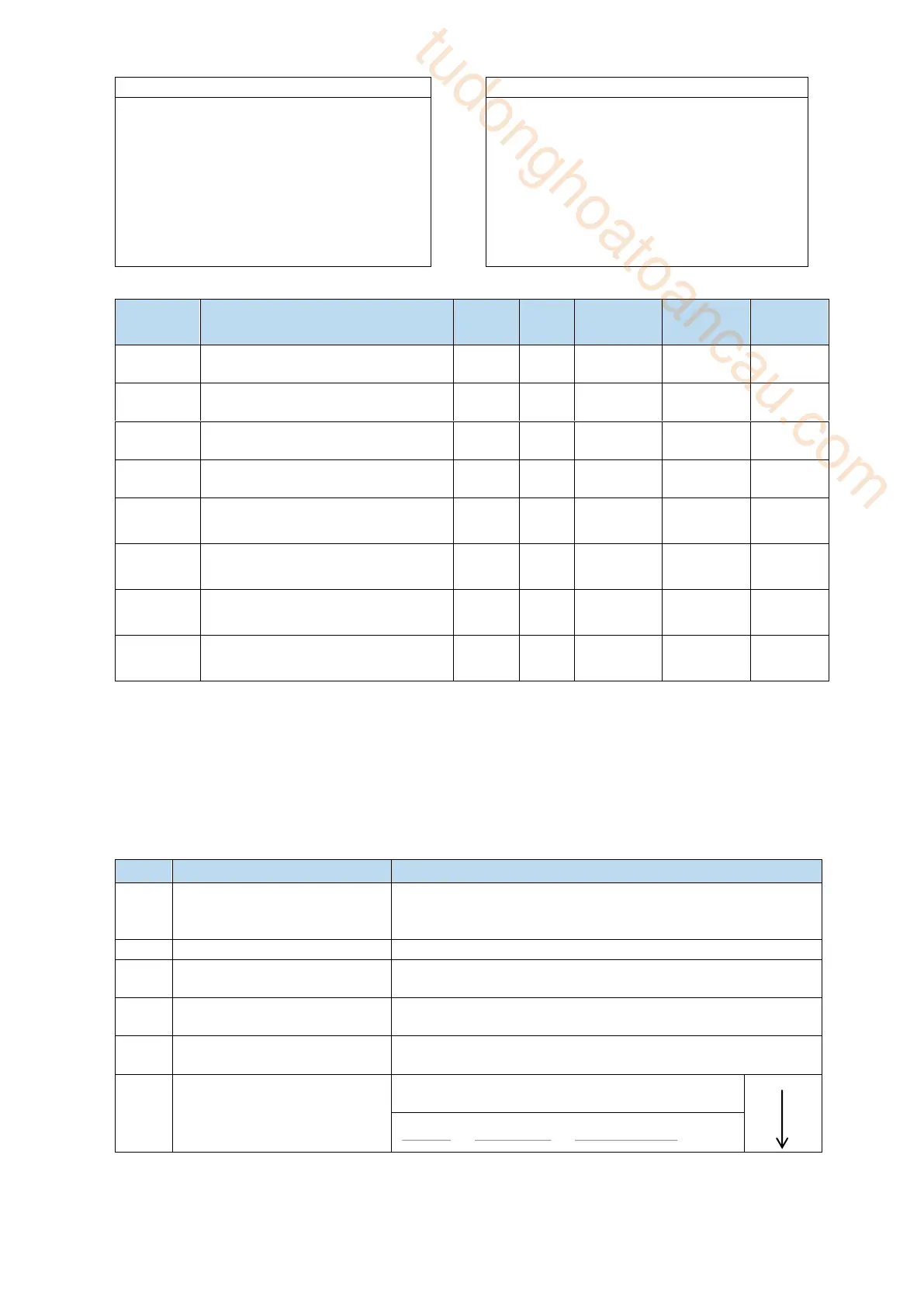

2. Calculation of Pulse Number per Rotation and Electronic Gear Ratio

Confirm the machine

specification

Confirm the deceleration ratio n:m(servo motor turns m

rotations while load turns n rotations), ball screw distance,

pulley diameter.

Confirm the encoder pulse

Confirm the servo motor encoder accuracy

Determine the actual distance or angle corresponding to 1

pulse of the controller

Calculate the command pulses

the load shaft rotates 1 circle

Based on the determined command unit, calculate the

command quantity n of the load shaft rotating for 1 revolution.

Calculate the pulses per

rotation M

Command pulse number of motor shaft rotating for 1 turn

M=N/(m/n).

Set the pulses per rotation

(P0-11/P0-12) or

Electronic gear ratio

(P0-13/P0-14)/(P0-92~95)

P0-11=M%10000

P0-12=M/10000

nN

m

M140P

130P

==

−

−

resolution

encoder

resolution

encoder

Note:

(1) In step 6, the effective priority of the number of pulses per revolution is higher than the

electronic gear ratio, that is, when P0-11 ~ P0-12 are all 0, P0-13 ~ P0-14 will take effect. In special

tudonghoatoancau.com

Loading...

Loading...