3-5

PREPARING FOR THE ROAD

BREAKAWAY CABLE

The law requires that any trailer with a

MTPLM (GVW) exceeding 750 kg must have

a braking system and it must work. If such a

trailer becomes detached from the tow vehicle

then these brakes must be applied

automatically by way of the breakaway cable.

This breakaway cable is an important part of

the management of the braking system and

when the trailer is built the braking system is

part of the certification process for the safe

use of the trailer - so any replacement parts

must be equivalent to the original parts fitted.

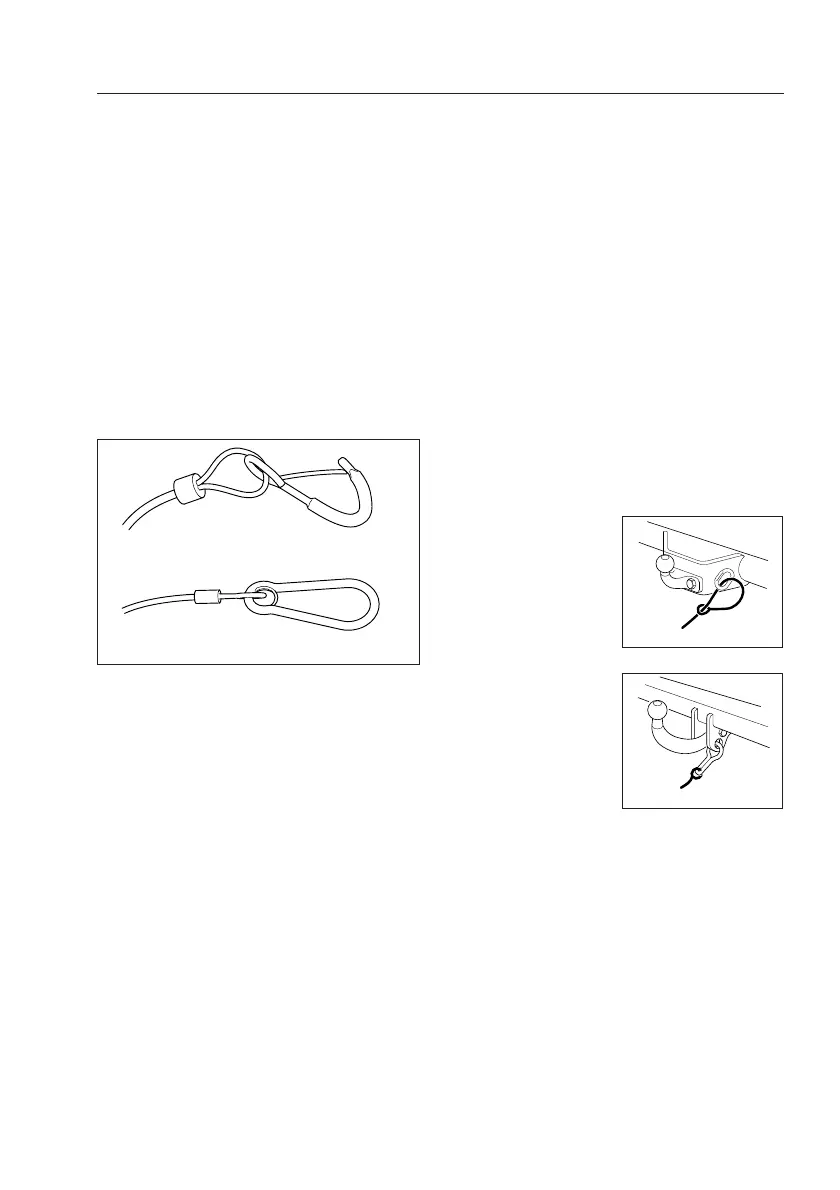

There are two types of breakaway cable in

use in the UK. One uses a spring clip, the

other uses a Karabiner clip.

Looking at the two clips it is easy to see that

there is a difference.

The spring clip type is designed to be hooked

back over the breakaway cable when it is

fitted to the tow vehicle and must always be

used this way.

The Karabiner type is designed to be secured

onto a mounting point on the tow vehicle, it

does not need to pass back over the cable to

secure it in place (but can if necessary).

So how should the breakaway cable be

secured to the tow vehicle? In the absence of

specific advice from the manufacturer/supplier

follow these simple guidelines:

Fixed tow ball systems

The cable with spring clip should be passed

behind the towbar assembly (where cable

length is sufficient) and then clipped back on

itself. The cable should be in as straight a

path as possible to ensure correct operation.

When the breakaway cable is attached,

check to ensure:

a) that the cable cannot snag in use on the

trailer coupling head, jockey wheel, or

any accessory e.g. a stabiliser, bumper

shield, cycle carrier etc.

b) that there is sufficient slack in the cable

to allow the towing vehicle and trailer to

articulate fully without the cable ever

becoming taut and applying the brakes.

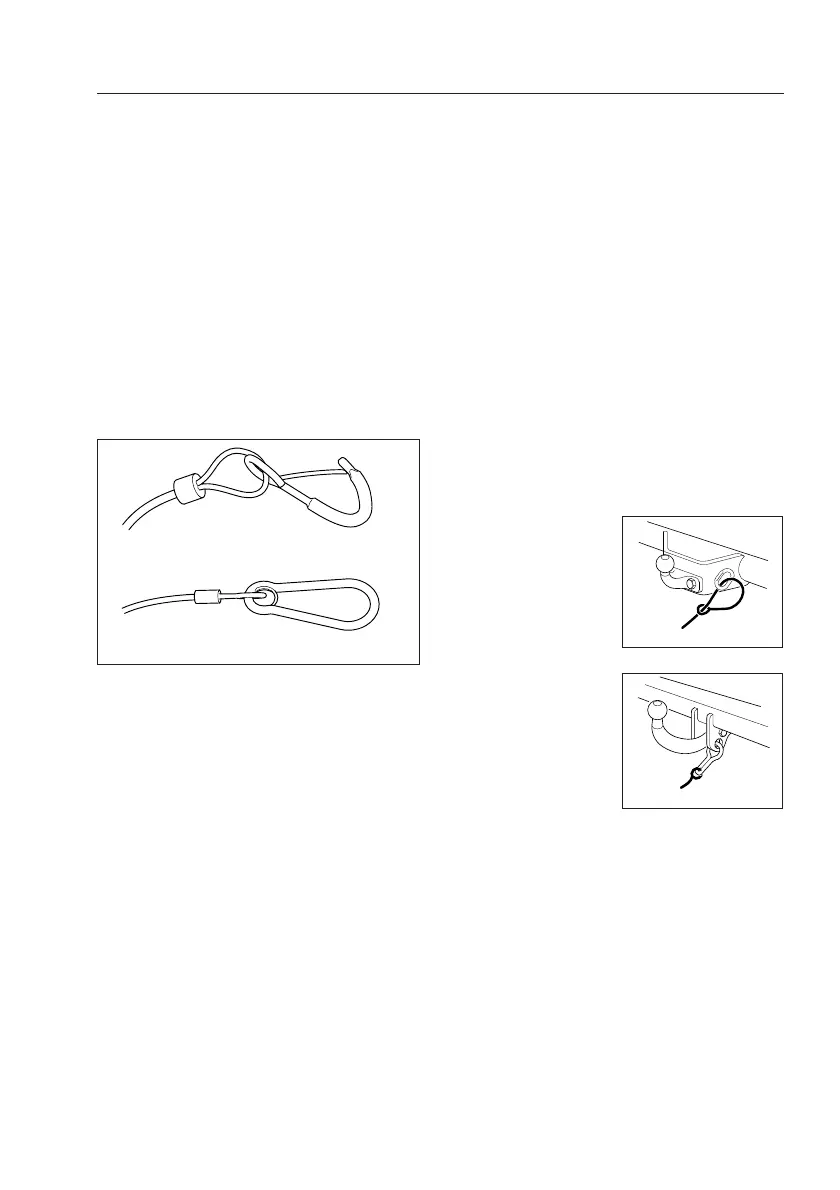

Where a designated attachment point is

provided on the towbar:

Either

a) Pass the cable

through the

attachment point

and clip it back on

itself (Fig. 1).

Or:

b) Attach the clip

directly to the

designated point

(Fig. 2). This

alternative must

be specifically

permitted by the

trailer

manufacturer since the clip may not be

sufficiently strong for use in this way.

Karabiner type clip

Spring type clip

Fig. 1

Fig. 2

Loading...

Loading...