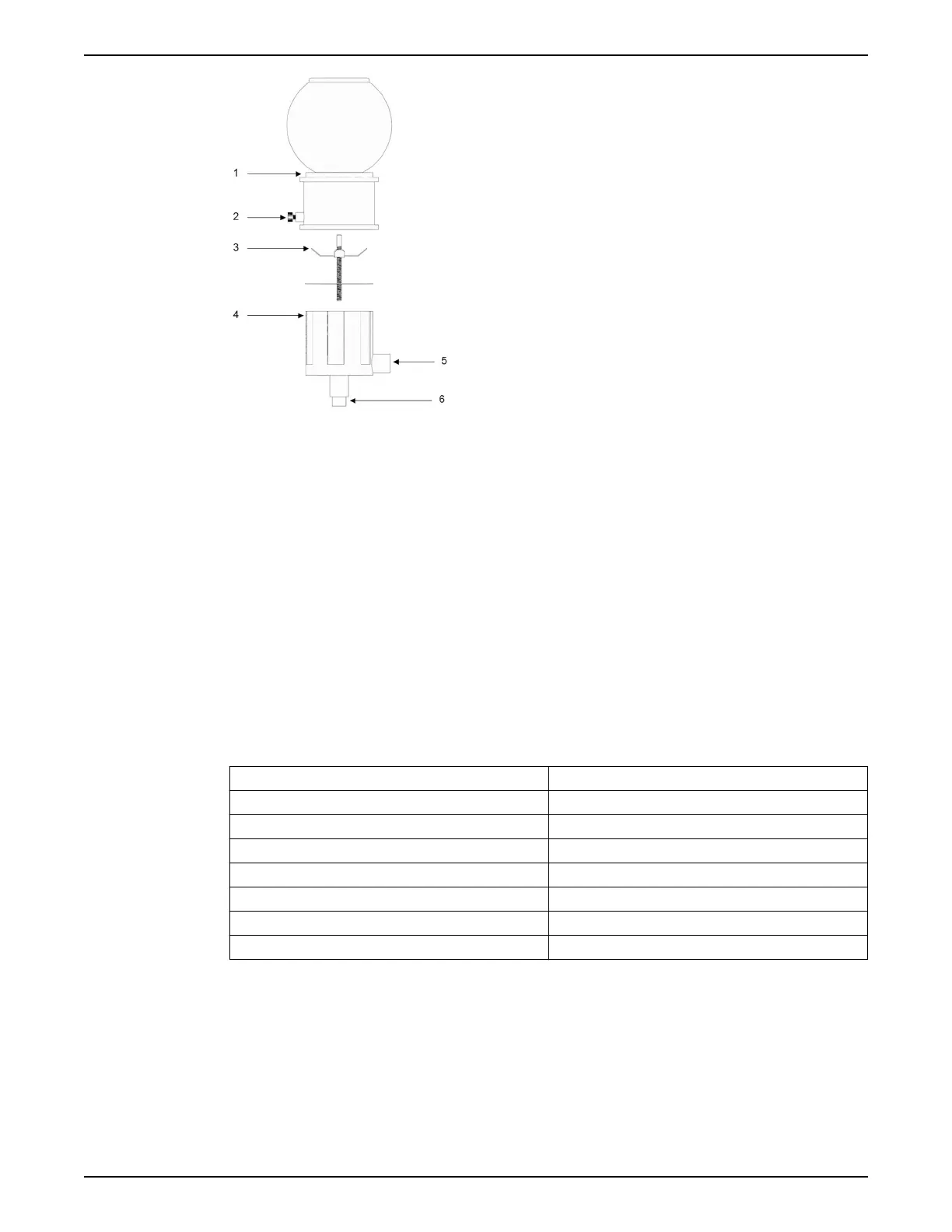

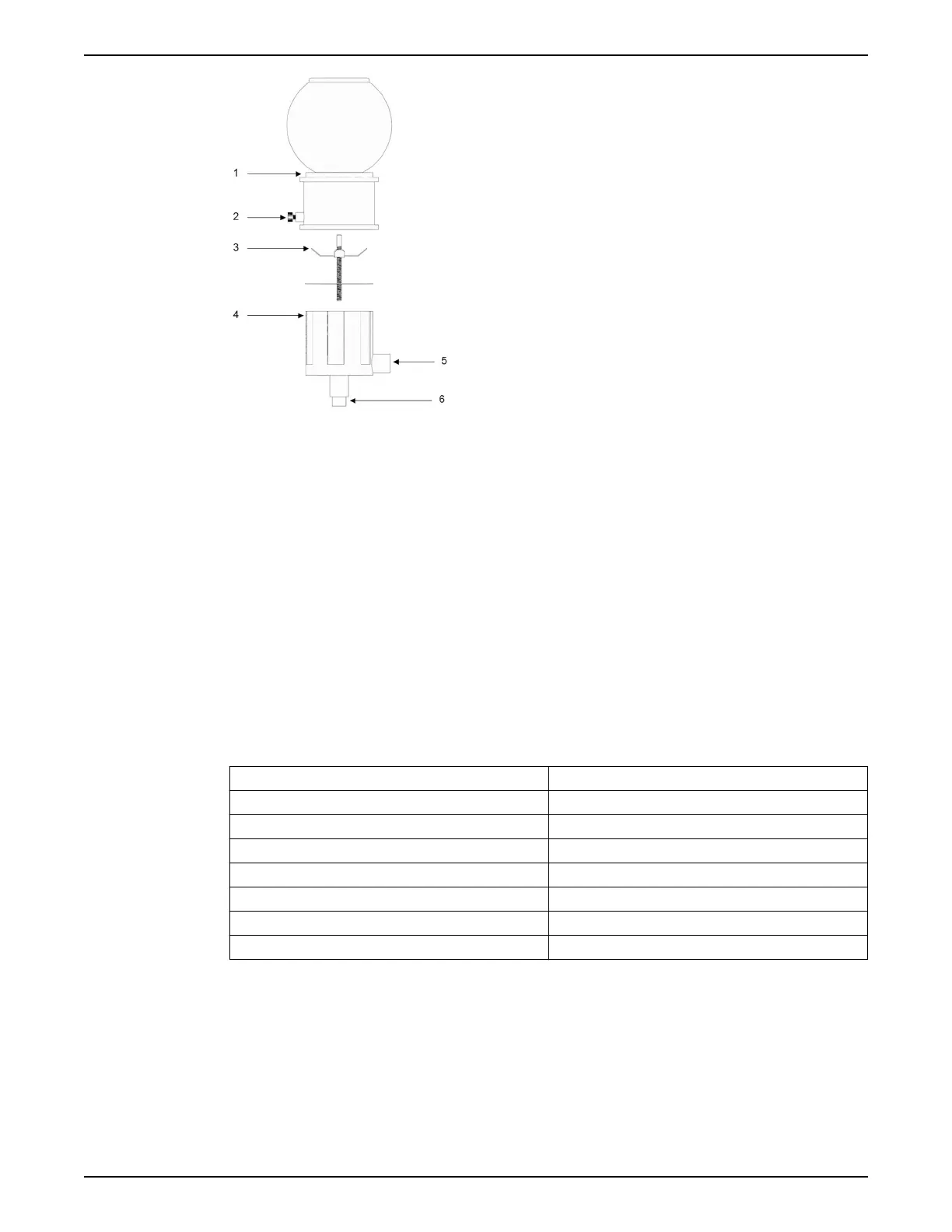

Figure 23: Oiler components

1. Upper oiler housing and bulb

2. Thumb screw

3. Oil level adjuster

4. Lower oiler housing

5. Primary process connection point

6. Alternate process connection port (plugged)

A Mobile Oil, DTE Medium, or equivalent, is recommended. See the following table for

acceptable oil specifications.

Note:

• Oils from different suppliers should not be mixed.

• Engine oils are not recommended.

• The oil should be non-foaming, well refined, high grade, straight cut, filtered mineral

oil. The oil must be free of water, sediment, resin, soaps, acid, and fillers of any kind.

Table 6: Recommended oil properties

Saybolt viscosity at 100°F (37.8°C) 215 SSU - 240 SSU

Saybolt viscosity at 210°F (99°C) 49 SSU

Viscosity index, minimum 95

API gravity 28 - 33

Pour point, maximum +20°F (-6.7°C)

Flash point, minimum 400°F (204°C)

Additives Rust and oxidation inhibitors

ISO viscosity 46

1. Disassemble the oiler by unfastening the thumb screw on the side. Separate the upper

housing and bulb from the lower housing. Remove the level adjuster from the interior

of the lower housing.

2. Spin the wing nut of the oil level adjuster to the desired level. The adjuster should be

set such that the oil level within the bearing housing will be centered with the lowest

ball of the bearing. The position of the sight glass is aligned with this level. See Figure

20: Recommended sight glass oil level on page 39 for more information.

6 Maintenance

42 e-XC INSTRUCTION MANUAL

Loading...

Loading...