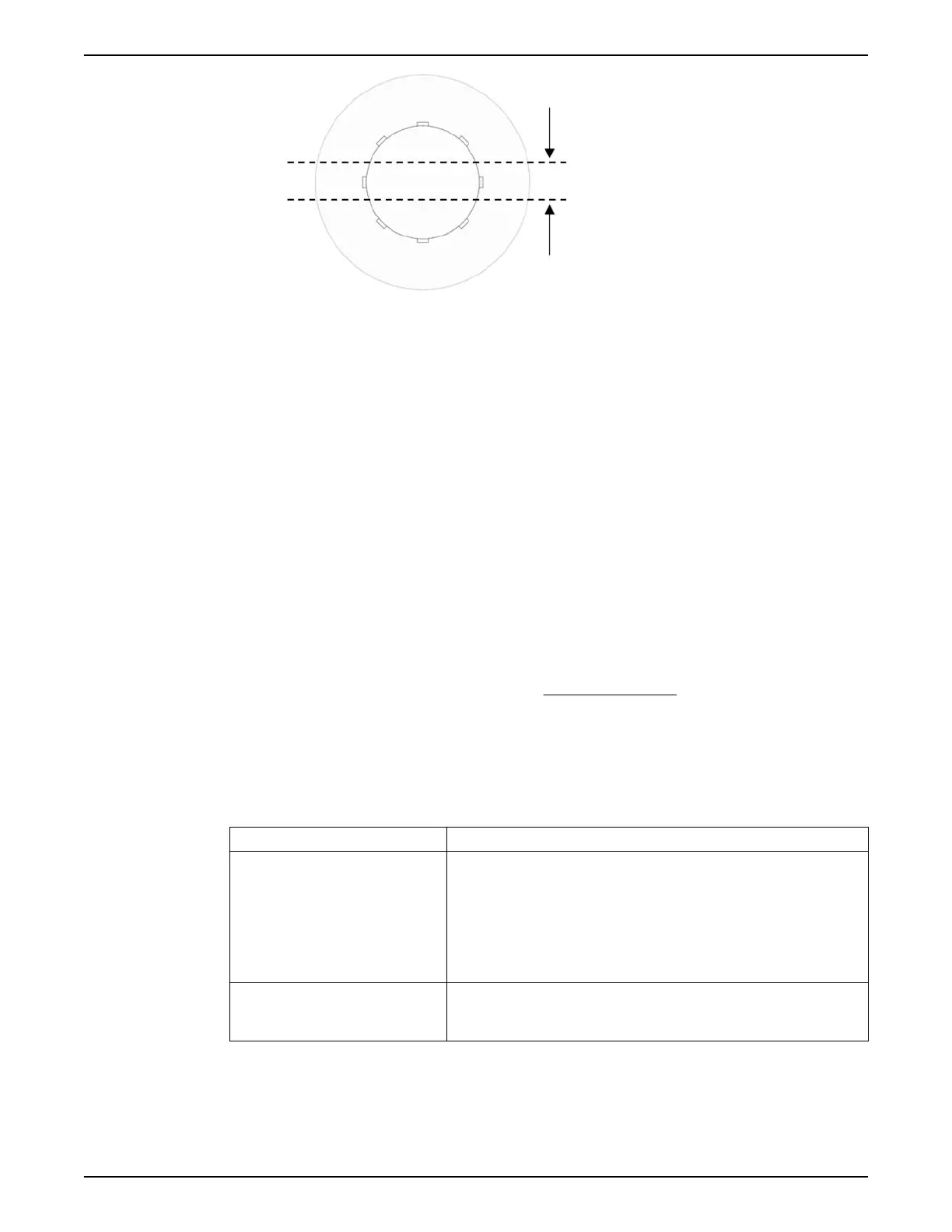

1. Maximum fill

2. Minimum fill

Figure 20: Recommended sight glass oil level

– Add oil if the oil level is at or below the minimum fill line. Drain excess oil from the

bearing cavity if the oil level is at or above the maximum fill line. Operating the

pump at oil levels outside of the indicated range will cause bearing damage.

Change the oil during routine maintenance to remove dirt and debris from the

bearing cavity. For more detailed lubrication instructions, refer to Lubricate the

bearings on page 39.

– In installations with moderate temperature changes, low humidity, and a clean

atmosphere, the oil should be changed after 1000 hours of operation. Conditions

may permit extended oil change periods anywhere from an additional 200-4000

hours. Inspect the oil frequently for moisture, dirt, or signs of breakdown especially

during the first 1000 hours of operation.

Bearing operating temperatures

The maximum operating temperature for ball bearings should not exceed 250°F (121°C).

If the temperature inside the bearing housing rises above this limit, shut down the pump

and determine the cause. Use the appropriate and properly calibrated equipment, such

as RTDs or thermocouples, when obtaining measurements

Note: Hand-held infrared thermometers are not recommended for accurate temperature

measurements of bearings or the bearing housing. IR measurements are highly sensitive

to surface properties, measurement distance, humidity, and proper emissivity calibration.

Furthermore, IR thermometers will only provide the surface temperature of the bearing

housing. Conditions inside the bearing housing may be hotter than the surface

temperature indicated by an IR thermometer

Coupling lubrication

Coupling type Lubrication requirements

Grid couplings Grid or gear tooth couplings (Falk Grid Steelflex or Falk Crowned Tooth

coupling for instance) are initially lubricated with Falk Long Term Grease

(LTG) and do not require relubrication for up to three years. If coupling leaks

grease, or is exposed to extreme temperatures or excessive moisture, more

frequent lubrication may be required.

Use coupling manufacturer’s recommended grease to provide trouble free

performance.

Polymer and elastomeric element-

type

Polymer and elastomeric element-type couplings are maintenance-free and

do not require lubrication. If other types of couplings are used, follow

maintenance instructions of coupling manufacturer.

6.2.1 Lubricate the bearings

Grease lubrication

Before you begin this procedure, make sure that you have these items:

6 Maintenance

e-XC INSTRUCTION MANUAL 39

Loading...

Loading...