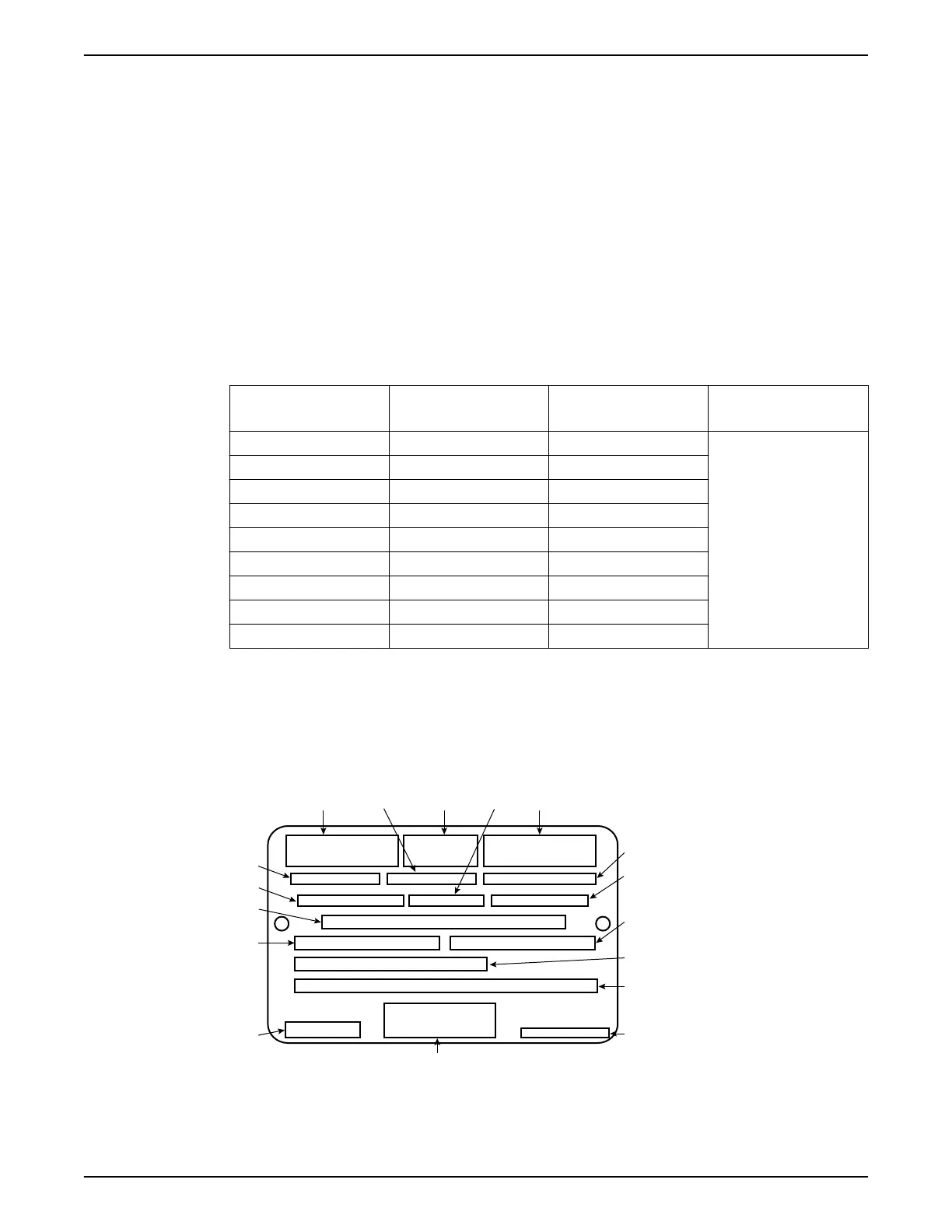

Seal operating limits

Xylem’s proprietary mechanical seals are designed specifically for the e-XC product line.

Therefore, seals are rated against the pump’s total working pressure. The table below

outlines the operating limits of both mechanical and packing seal configurations. For

more mechanical seal and packing details, view the ‘e-XC Performance Curves and

Technical Data’ brochure.

As a general rule of thumb, the pressure the mechanical seal experiences is 1.15 times the

suction pressure of the pump in water applications. For fluids with greater viscosities, this

multiplier is greater. Consult factory for more specific information. Allowable pump

suction pressure is equal to the maximum working pressure minus the discharge pressure.

Note that the life of a mechanical seal depends on the cleanliness of the pumped fluid.

Due to the diversity of operating conditions, it is not possible to provide a definitive

guarantee of seal life. In clean water applications, typical mechanical seal life spans two to

three years.

Table 1: Operating limits

Seal Name Description Max Pressure

psi [bar]

Max Temperature

°F [°C]

MR1 Metric metal pusher 450 [31]

250 [121]

MR2 Metric rubber bellow 232 [16]

MR3 Imperial metal pusher 450 [31]

MR4 Imperial rubber bellow 175 [12]

MR5 Metric cartridge on shaft 450 [31]

MR6 Imperial cartridge on shaft 450 [31]

MR7 Metric cartridge on sleeve 450 [31]

MR8 Imperial cartridge on sleeve 450 [31]

Packing Style 608D graphite 300 [20.7]

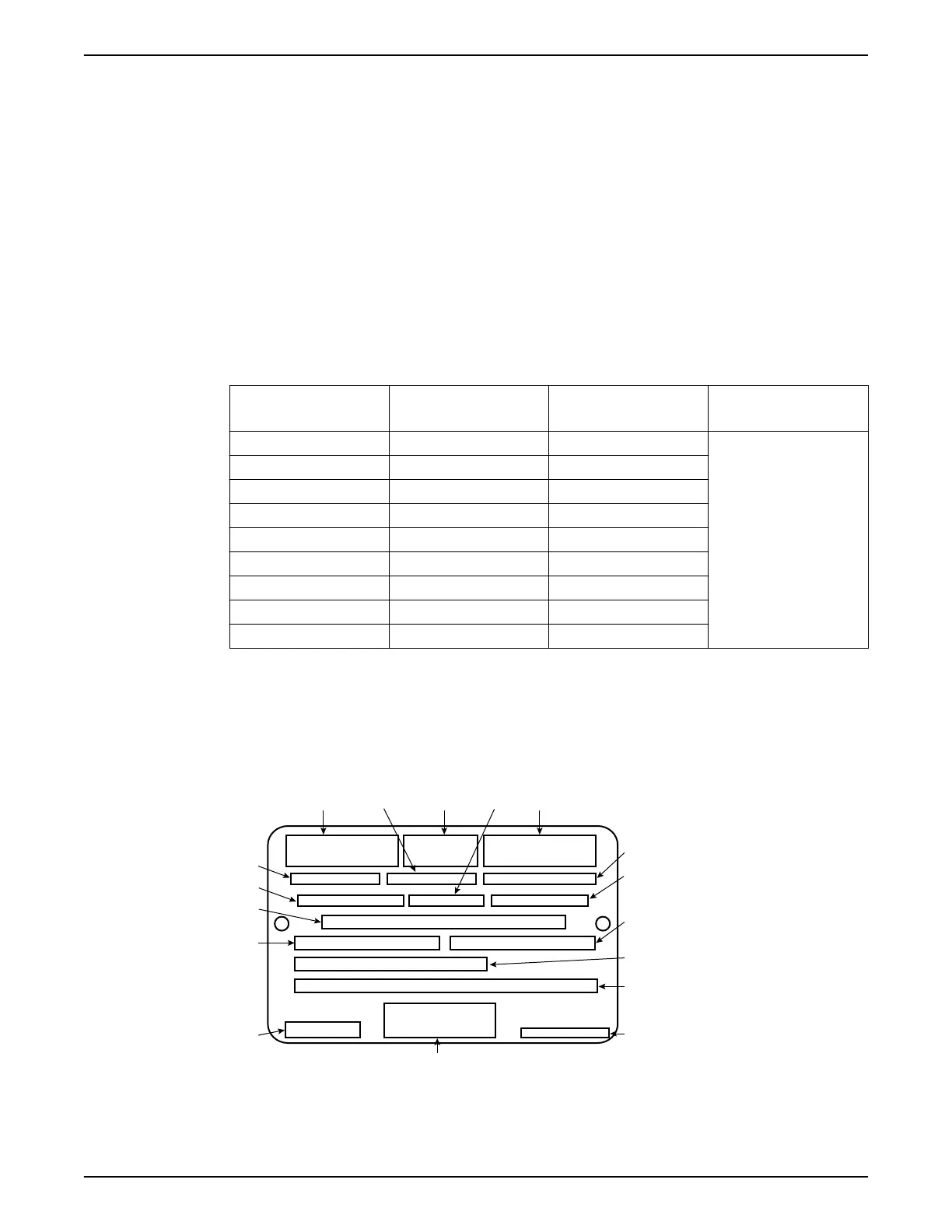

3.3 Nameplate rating information

e-XC pumps are designated by a series of numbers. The pump nameplate gives

identification and rating information.

Permanent records for this pump are referenced by the serial number. This number must

be used with all correspondence and spare parts orders.

1 532 4

6

7

8

9

10

11

12

13

14

15

16

17

Figure 2: Rating plate

Legend

3 Product Description

e-XC INSTRUCTION MANUAL 11

Loading...

Loading...