CAUTION

Protect the hydraulic system from dirt and

contaminants when servicing the hydraulic

system.

Never operate the pump without the proper

amount of oil in the hydraulic system. The

operation of the hydraulic pump with low oil levels

will damage the pump.

Check for leaks by looking for oil under the lift truck

and where the lift truck has been parked. Visually

inspect the hydraulic system and hoses. Small oil

leaks may appear as wet, oily leaks or unusually dirty

areas where dirt and dust sticks to oil that has slowly

leaked out.

Drive Tire, Load Wheels, Casters, and

Frame

WARNING

When the drive tire has been installed, check all

wheel nuts after 2 to 5 hours of operation. When

the nuts stay tight after an 8-hour check, the

interval for checking the torque can be extended to

350 hours. Refer to the Maintenance Schedule in

this section.

If the drive tire has recently been installed, check to

ensure the lug nuts are properly tightened to

120 N•m (88 lbf ft). When installing, snug all the nuts,

then tighten to half the torque value, then tighten to the

full torque value. Tighten the nuts in a cross pattern to

properly seat the wheel to the hub.

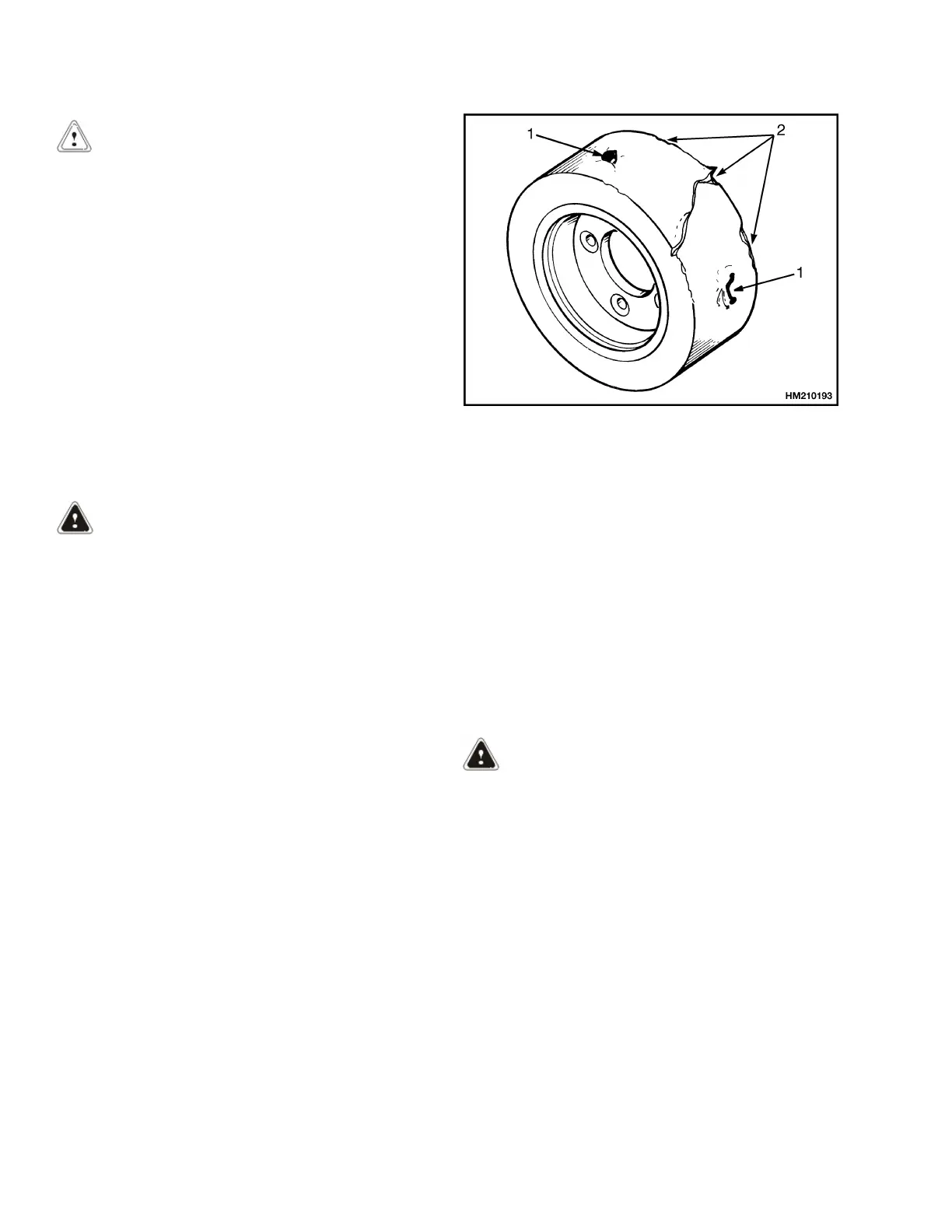

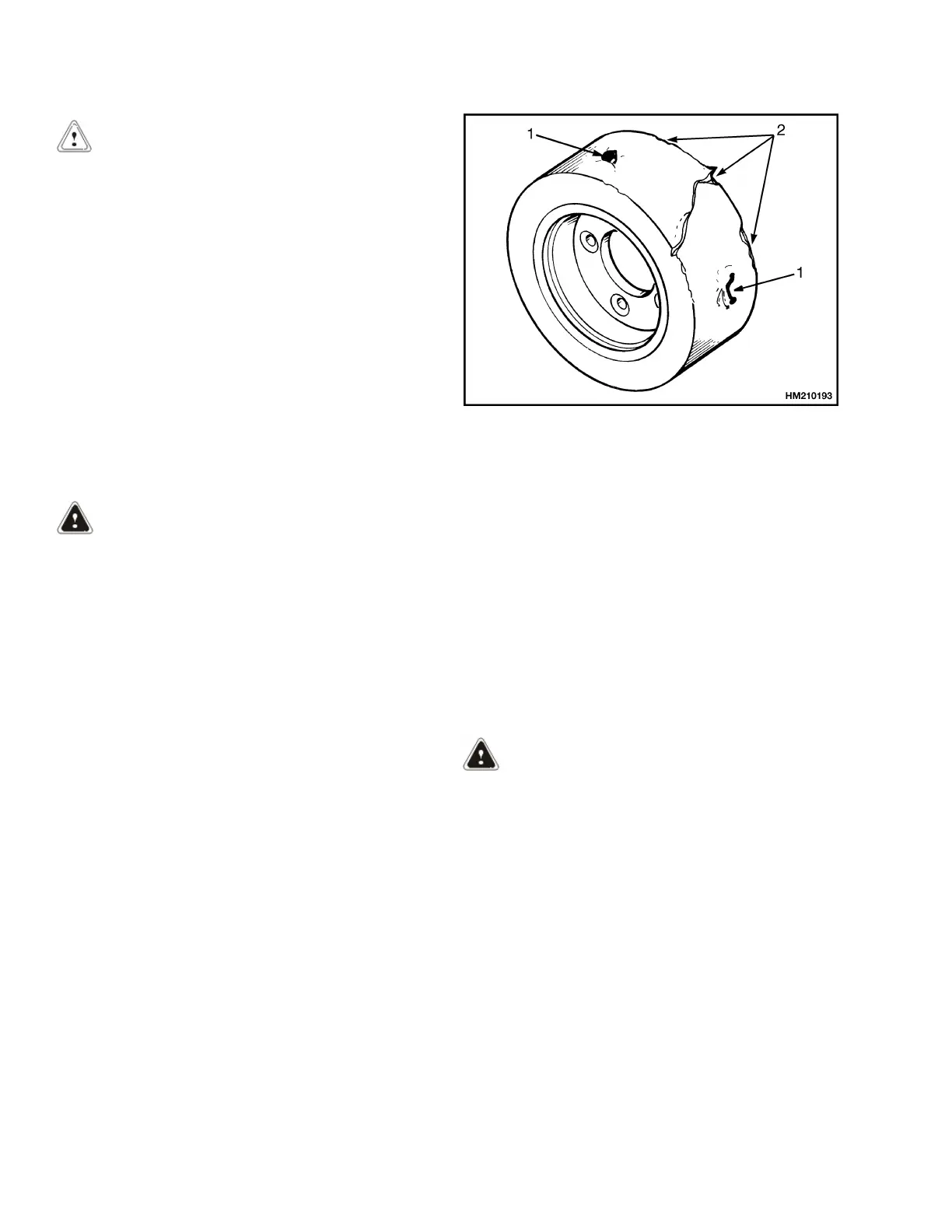

Inspect the tire for embedded rocks, glass, wire,

pieces of metal, holes, cuts, and other damage. See

Figure 6. Remove any object that will cause damage.

Check for loose or missing nuts and broken studs.

Remove any wire strapping or other material that is

wrapped around the axle to prevent damage to the

axle seal.

1. REMOVE EMBEDDED OBJECTS

2. CHECK FOR CUTS, SPLITS, AND OTHER

DAMAGE

Figure 6. Tire Check

Inspect the frame for structural damage and loose/

missing hardware. Make certain all covers are in place

and secured before operating the lift truck. Inspect the

load wheels. Loose or crooked load wheels may

indicate a bearing failure. If failure is suspected, raise

the lift truck slightly and check that the load wheels are

secure on the axles and rotate smoothly. See How to

Put a Lift Truck on Blocks. Repair or replace as

necessary.

Standard Caster Adjustment:

WARNING

In normal operation, the casters should

continuously contact the floor. As the drive tire

wears, the frame will move closer to the floor and

the casters will carry more of the load. If the caster

shims are not periodically adjusted, they will bear

too much of the lift truck weight and reduce the

necessary load on the drive tire. This can interfere

with the ability of the drive tire to control steering

and stopping functions of the truck.

Maintenance Procedures Every 8 Hours or Daily 8000 YRM 1666

10

Loading...

Loading...