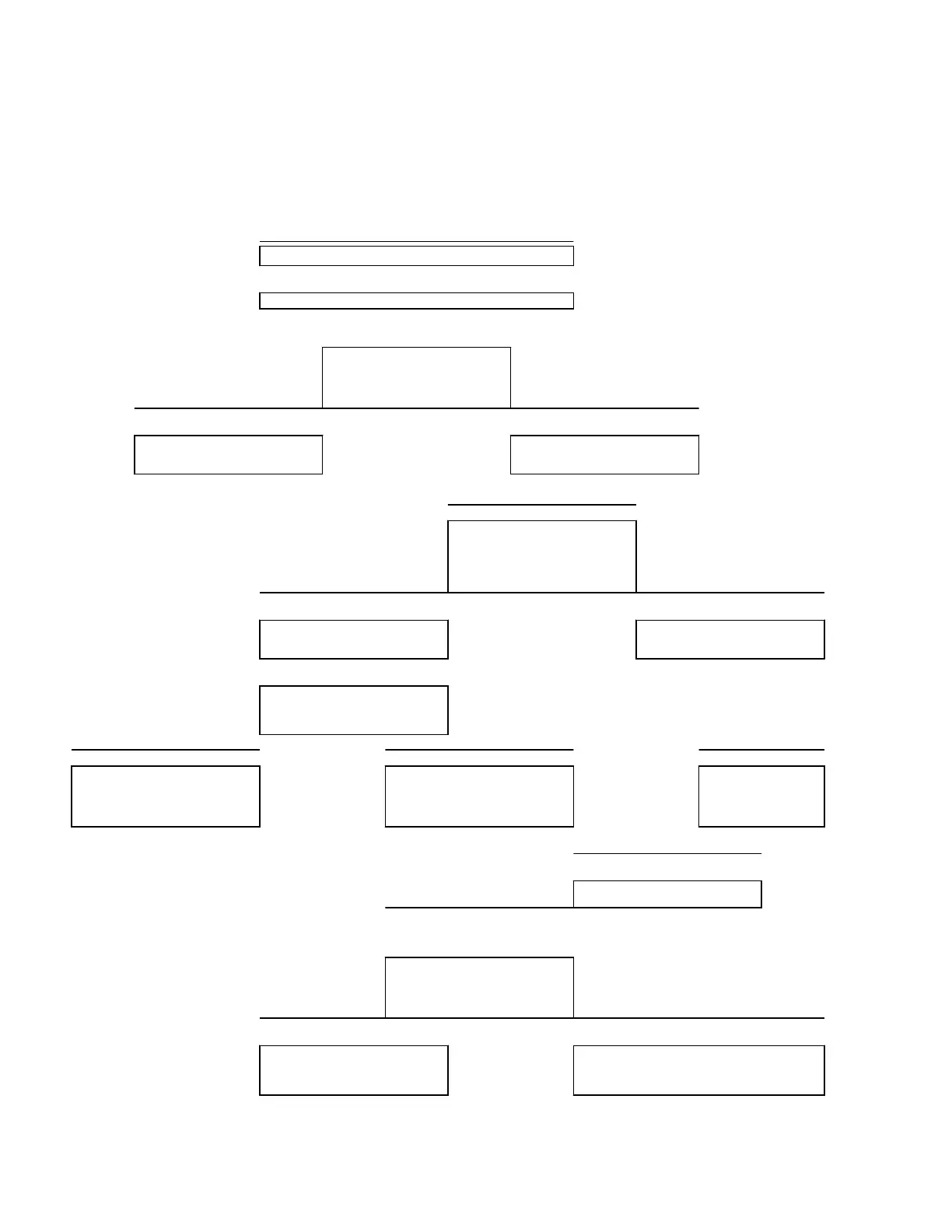

Troubleshooting

Table 2. BATTERY TROUBLESHOOTING GUIDE

1 BATTERY INSPECTION PROCEDURES

|

↓

OBSERVE ALL SAFETY REQUIREMENTS

|

CHECK

↓

INCORRECT

|

|

|

←————

BATTERY SIZE FOR CORRECT AMP HR.

RATING ON TRUCK CAPACITY PLATE

AGAINST AMP HR. RATING LOCATED ON

SIDE OF BATTERY OR STAMPED ON

BATTERY POSITIVE TERMINAL.

————→ CORRECT

|

|

|

|

↓

|

↓

REPLACE BATTERY WITH CORRECT

AMP HR. BATTERY

——————————————————→

VISUALLY INSPECT BATTERY

CONDITION FOR MAINTENANCE

NEGLECT OR PHYSICAL ABUSE

|

CHECK FOR

↓

POOR

MAINTENANCE

|

|

←————

1. MISSING VENT CAPS

2. BATTERY CORROSION

3. CABLE CONDITION/ENDS

4. ELECTROLYTE LEVEL OF BATTERY

CELLS

5. COLOR OF ELECTROLYTE (CLEAR)

————→

1

GOOD

MAINTENANCE

|

|

|

↓

|

↓

CORROSION ←—————

REPLACE BATTERY OR MAKE

NECESSARY REPAIRS

——————

↓

UNPLUG BATTERY AND CHECK

BATTERY VOLTAGE - 2.1 VOLTS PER

CELL

|

|

|

↓

ELECTROLYTE LEVEL

|

|

|

|

|

|

|

|

IF ELECTROLYTE IS DARK, REPLACE

BATTERY AND CONTACT BATTERY

VENDOR

|

|

|

|

CORRECT

VOLTAGE

|

|

LOW

VOLTAGE

|

|

| |

|

|

↓ ↓

|

↓

IF WASHING IS REQUIRED - REMOVE

BATTERY FROM TRUCK AND WASH

WITH A NEUTRALIZING AGENT (BAKING

SODA AND WATER, VENT CAPS MUST

BE IN PLACE)

—————————→

IF ELECTROLYTE LEVEL IS LOW - ADD

DISTILLED WATER ONLY, RECHARGE

|

|

|

|

|

REPLACE OR RECHARGE

BATTERY

|

|

|

|

|

↓

|

|

|

↓

CORRECT

VOLTAGE

|

|

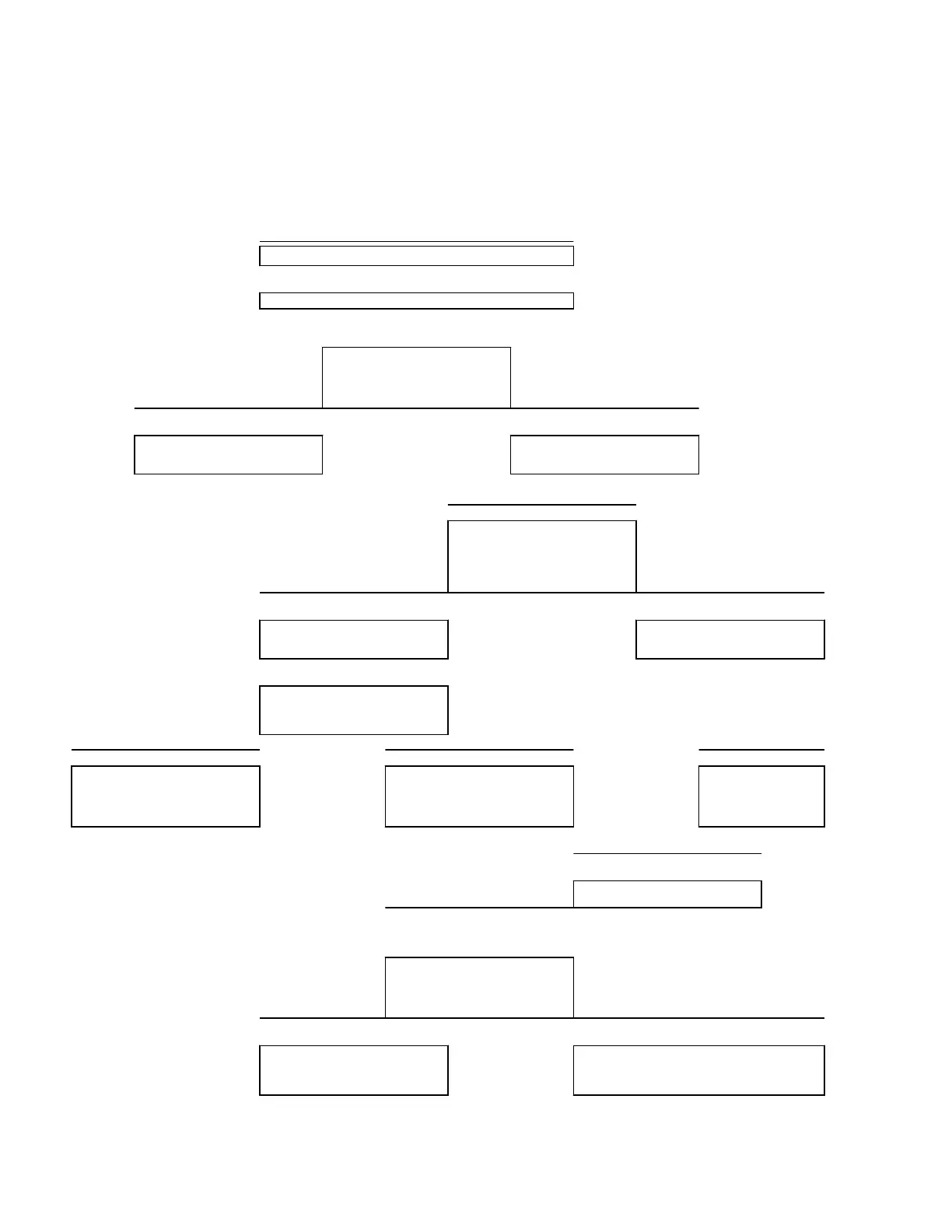

2 BATTERY LEAKAGE TEST

|

←

|

|

|

↓

|

|

|

|

SERVICE PERSONNEL SHOULD

REPLACE BATTERY WHENEVER

POSSIBLE TO AVOID EXTENSIVE

DOWNTIME WHEN TROUBLESHOOTING

SCR PROBLEMS

|

|

|

|

|

|

↓

|

↓

INDEX AND FOLLOWING THE SIDE

MARKED 1 GOOD MAINTENANCE FOR

THE NEXT TROUBLESHOOTING AND

TEST PROCEDURE

CHECK FOR BATTERY LEAKAGE FROM POS/NEG SIDE

OF BATTERY TERMINALS TO TRUCK FRAME - USING

THE 500 MA SCALE ON THE VOLT-OHM METER,

READING SHOULD BE LESS THAN 100MA.

Troubleshooting 2240 YRM 0001

18

Loading...

Loading...