7-83

Power unit

POWR

TIP:

In the second tightening stage for the con-

necting rod bolts b, mark the connecting rod

bolts and the connecting rod cap with identifi-

cation marks e, and then tighten the bolts

90° from the marks on the connecting rod

cap.

6. Remove the connecting rod cap, and

then measure the width of the

compressed Plastigauge (PG-1) on the

crankpin.

Selecting the crankpin bearing

When replacing the crankpin bearing, select

the bearing as follows:

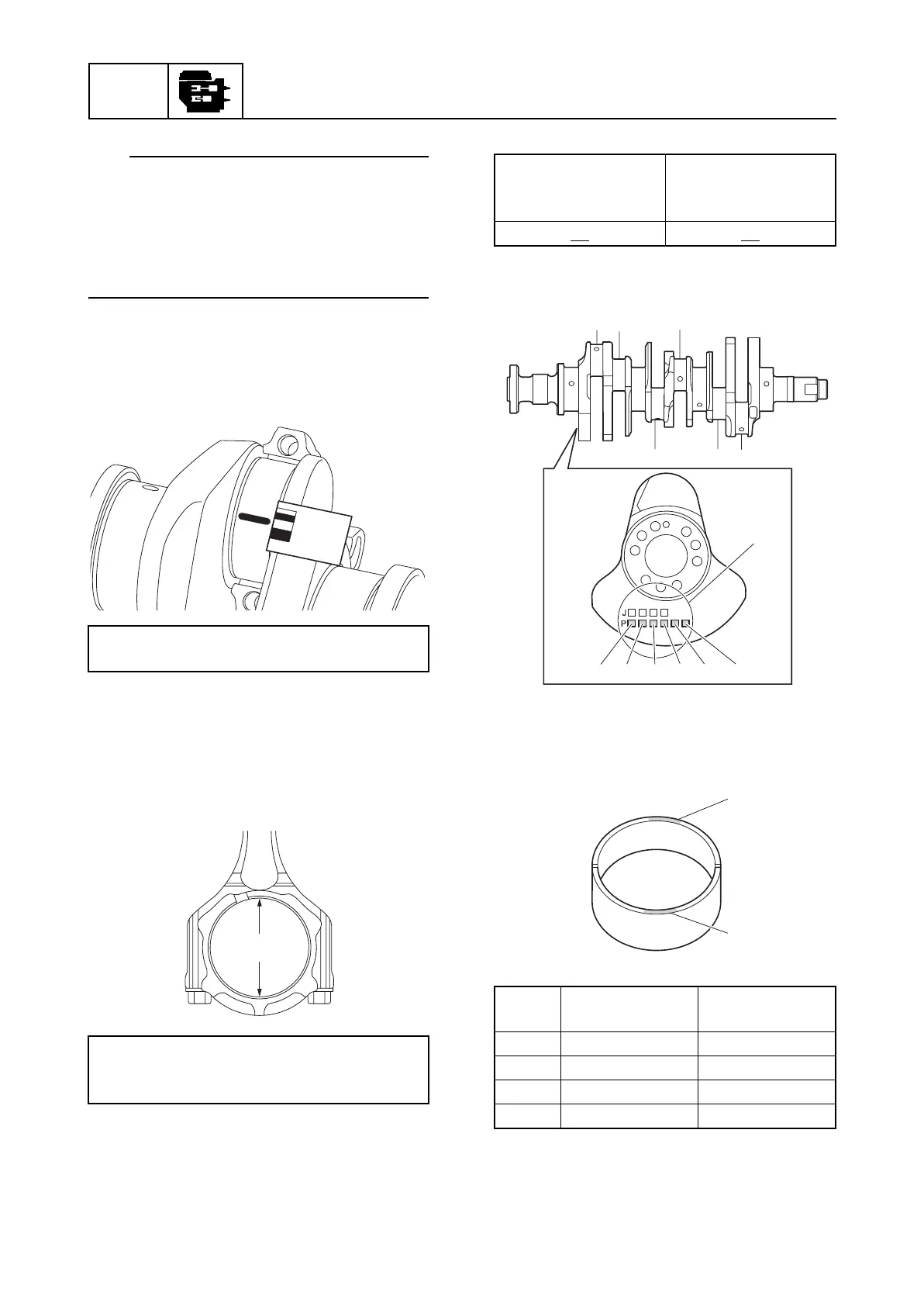

1. Measure the connecting rod big end

inside diameter a.

Example:

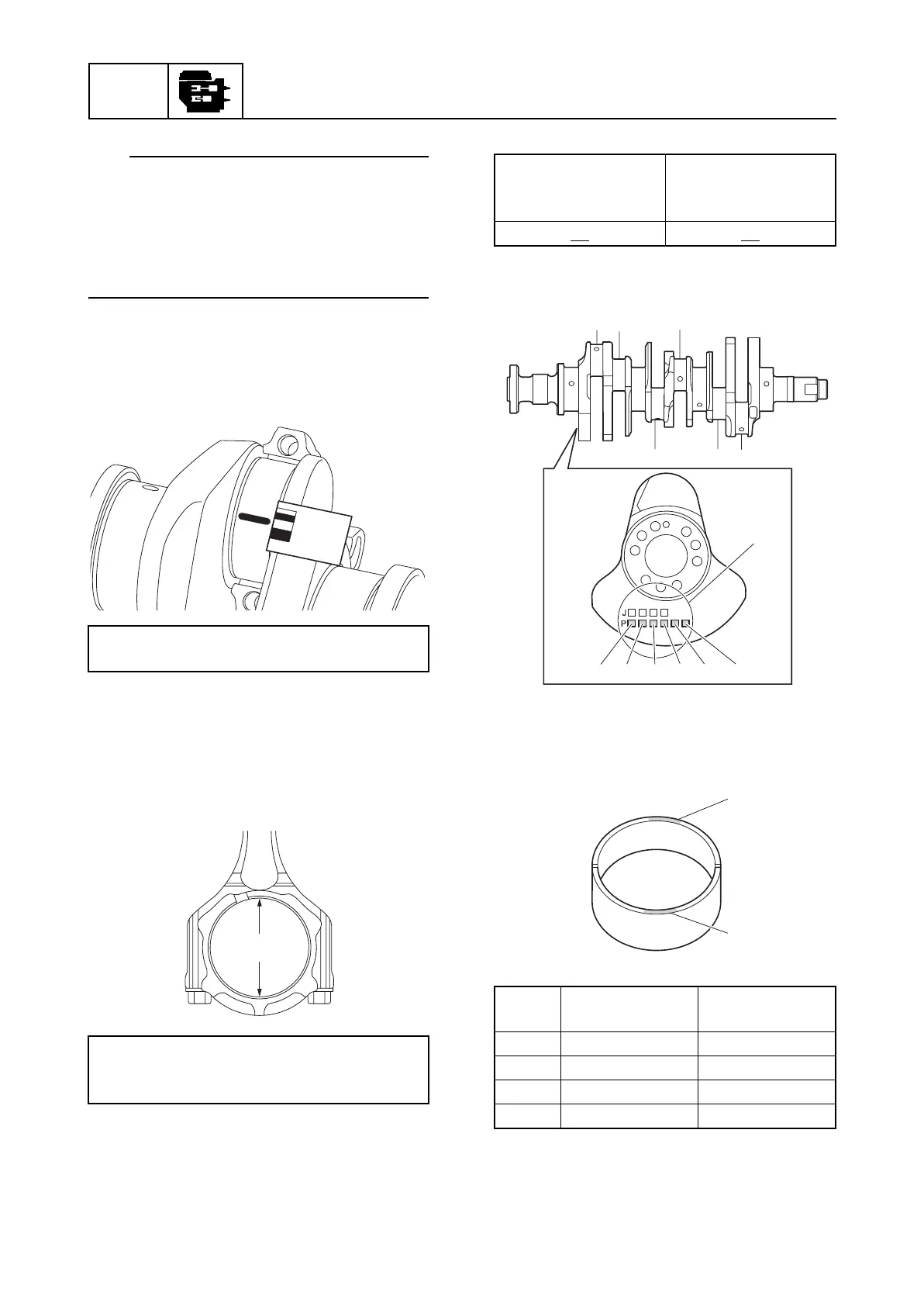

2. Check the crankpin mark b on the

crankshaft.

3. Select the suitable colors c for the

crankpin bearing from the “Crankpin

bearing selection table.”

Crankpin oil clearance (reference data):

0.025–0.050 mm (0.0010–0.0020 in)

Connecting rod big end inside diameter a:

55.990–56.010 mm

(2.2043–2.2051 in)

a

Connecting rod big

end inside diameter

a

Number in table

56.005

mm 05

Upper bearing

color

Lower bearing

color

d Ye ll o w Ye l l o w

e Yellow Green

f Green Green

g Blue Green

P1

P1

P2

P2

P3

P3

P4

P4

P5

P5

P6

P6

b

c

c

Loading...

Loading...