22

Operation Method

Program Operation

This operation is used to change the temperature according to the setting temperature and time.

Program types

Six patterns of program types maximum can be input.

PrG1 - 1 program pattern using 30 steps maximum can be created.

Pat1

PrG2

Pat2

2 program patterns using 15 steps maximum can be created.

Pat1

Pat2

PrG3

Pat3

3 program patterns using 10 steps maximum can be created.

Before inputting program

…

Input program patterns before program operation.

① Check the number of steps in a created program and their setting temperature/time. Use the

program preparation sheet in pages 29 and 30 to check.

② Check the temperature rise/fall capability of the unit. Set the time within the capability above.

Suppose, for instance, that in the unit which has capability of increasing or decreasing

temperature by 50℃ within 30 minutes, about 30 minutes is needed to increase or decrease

temperature by 100℃ from current temperature

Repeat function:

Repeat function is useful in case the operation uses the program repeating the same program

steps. Refer to page26 for the function.

③ Check if the controller has sufficient free pattern for the number of steps to be created. The steps,

however, using the repeat function mentioned above are not counted.

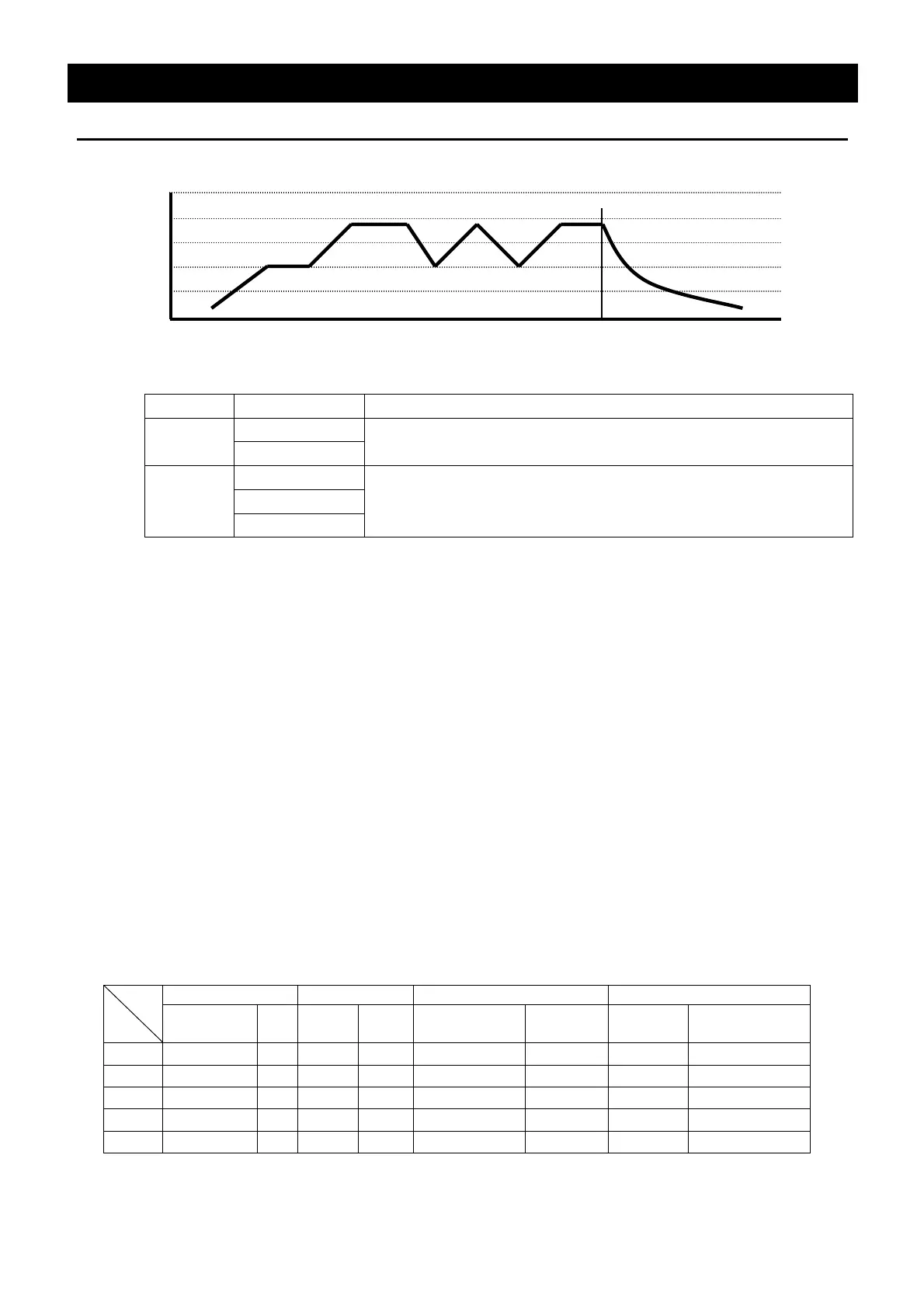

Temperature fall/rise curve for DPC type

The temperature fall curve and temperature rise curve for DP type are shown below.

The numeric value indicates the necessary time between temperatures (ex: about 15 minutes is

needed to increase temperature from 100℃ to 150℃ for DP33C). Temperature stability time after

reaching to the setting temperature is necessary to be added. Make sure to conduct a test run

before setting the optimum time.

Condition: room temperature 23℃, no load, exhaust opening fully opened (unit: minute)

DP23C DP33C DP43C DP63C

Rise

Fal

l

Rise

Fall

Rise

Fall

Rise

Fall

240℃ 10 - 10 - - - - -

200℃ 15 5 15 5 30 5 35 5

150℃ 15 15 15 20 20 20 30 25

100℃ 15 20 15 30 20 30 30 40

50℃ 5 45 5 60 10 75 25 120

Temp.

Time

△ Stop △ Start

Loading...

Loading...