5 SUPPLEMENT

5-2

5-1 Detail of Preparatory Function

1. G-code (Group00)

A. Dwell

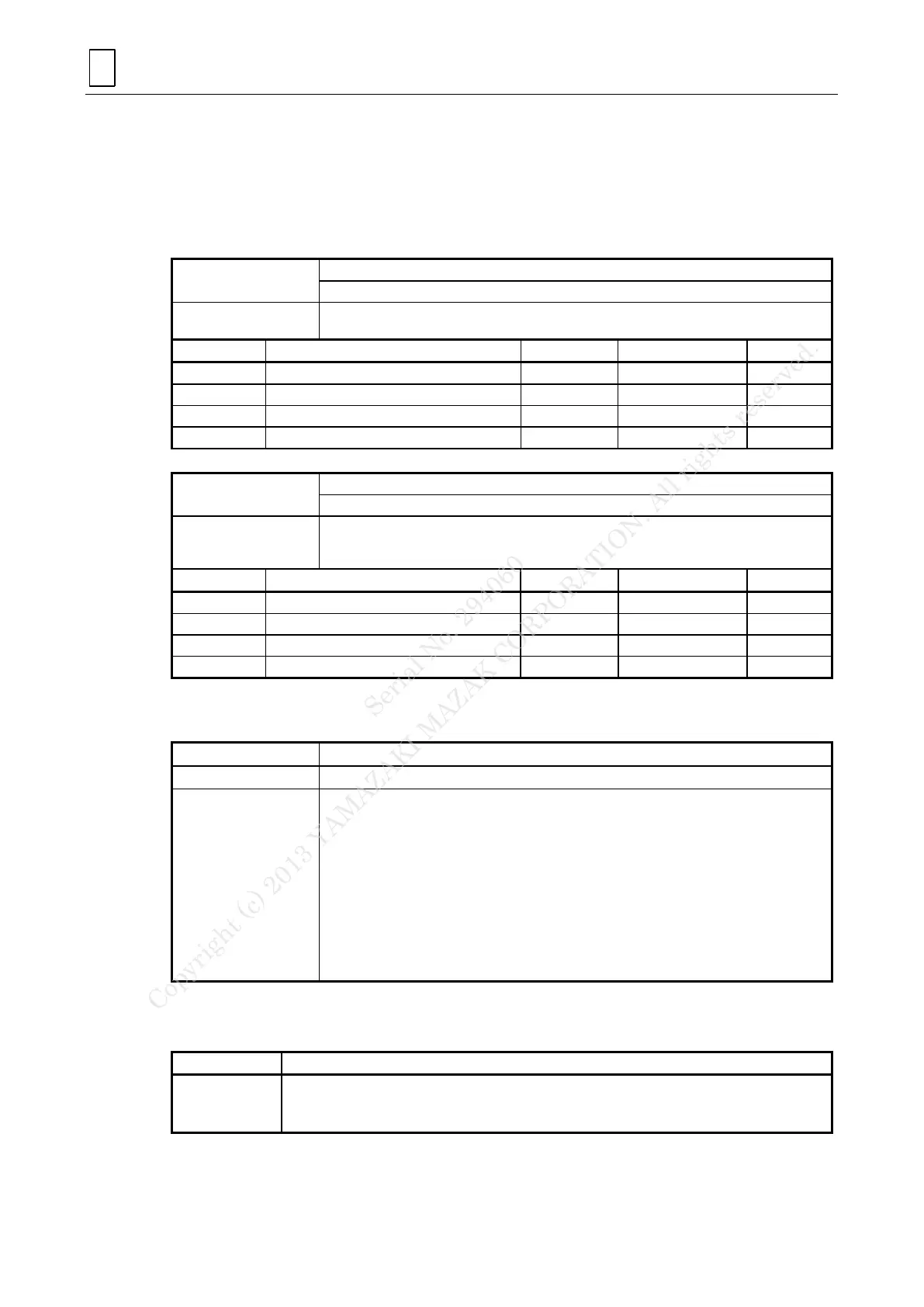

1. Command

Setting command G04 in the feed-per-second mode (command G94) delays the start of

execution of the next block for the specified time.

Delay that elapses before the next block

Delay that elapses before the next block

Setting command G04 in the feed-per-revolution mode (command G95) suspends the start

of execution of the next block until the spindle has rotated the specified number of

revolutions.

Number of revolutions to next block

Number of revolutions to next block

B. High-speed machining mode

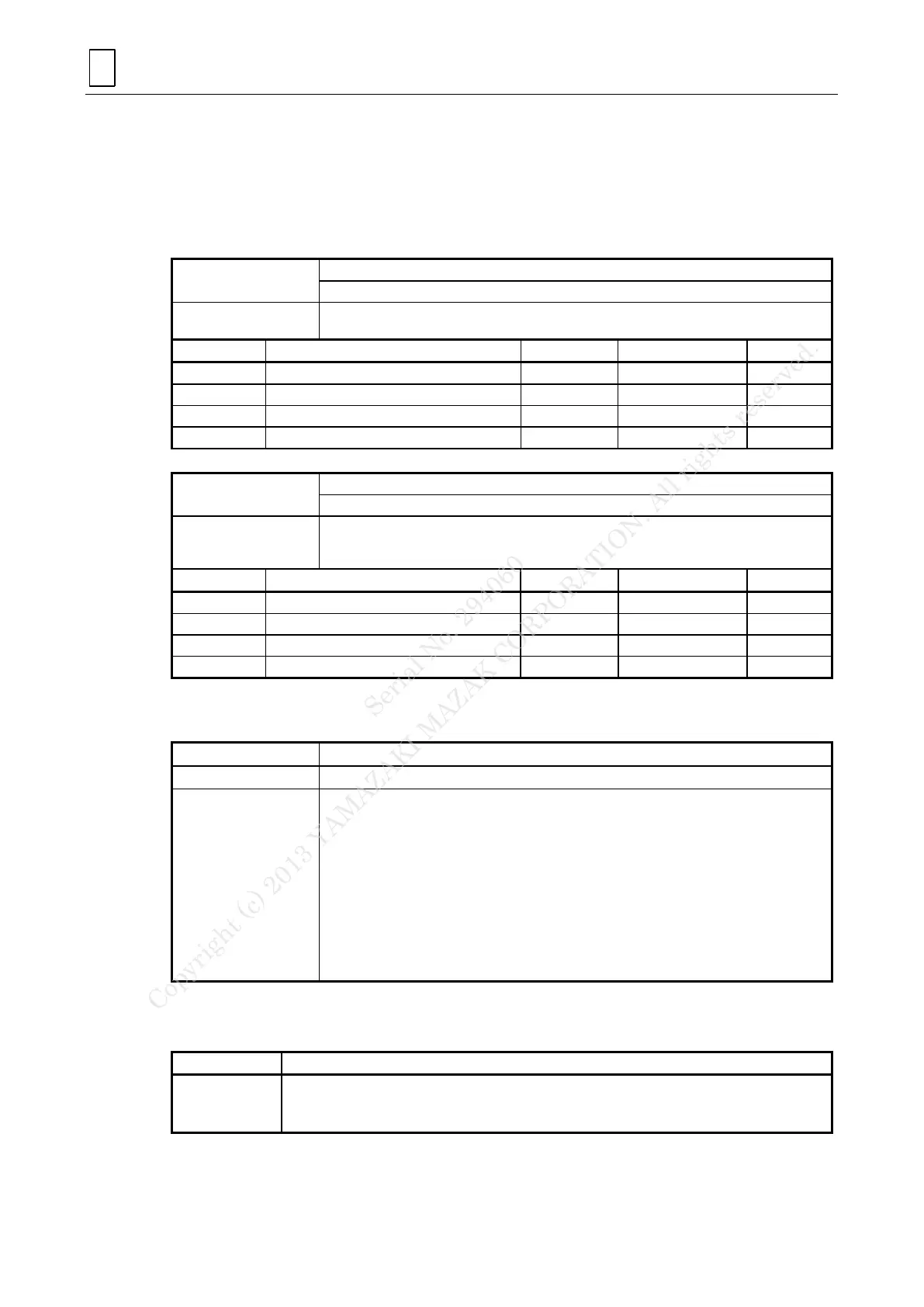

1. Command

The high-speed machining mode feature allows high-speed execution of programs used

for the machining of free-curved surfaces that have been approximated using very small

lines. In high-speed machining mode, microsegment machining capabilities improve by

several times, compared with conventional capabilities. This allows the same machining

program to be executed at several times the original feed rate, and thus the machining time

to be reduced significantly. Conversely, a machining program that has been approximated

using lines of several fractions of the original segment length, can also be executed at the

same feed rate, so more accurate machining is possible. Combined use of the high-speed

machining mode and the shape correction function allows more accurate machining to be

implemented. If, moreover, a protruding section exists in the microsegment machining

program, smooth interpolation can be conducted automatically by removing this illegal

path.

Absolute data input as well as incremental data input is applicable, indeed, but the former input

mode requires the validation of bit 5 of the F84 parameter.

Type of position data input in the high-speed machining mode

0: Always incremental data input

1: According to the input mode before selection of the high-speed machining mode

Serial No. 294060

Copyright (c) 2013 YAMAZAKI MAZAK CORPORATION. All rights reserved.

Loading...

Loading...