SUPPLEMENT 5

5-69

2. M-code (ATC)

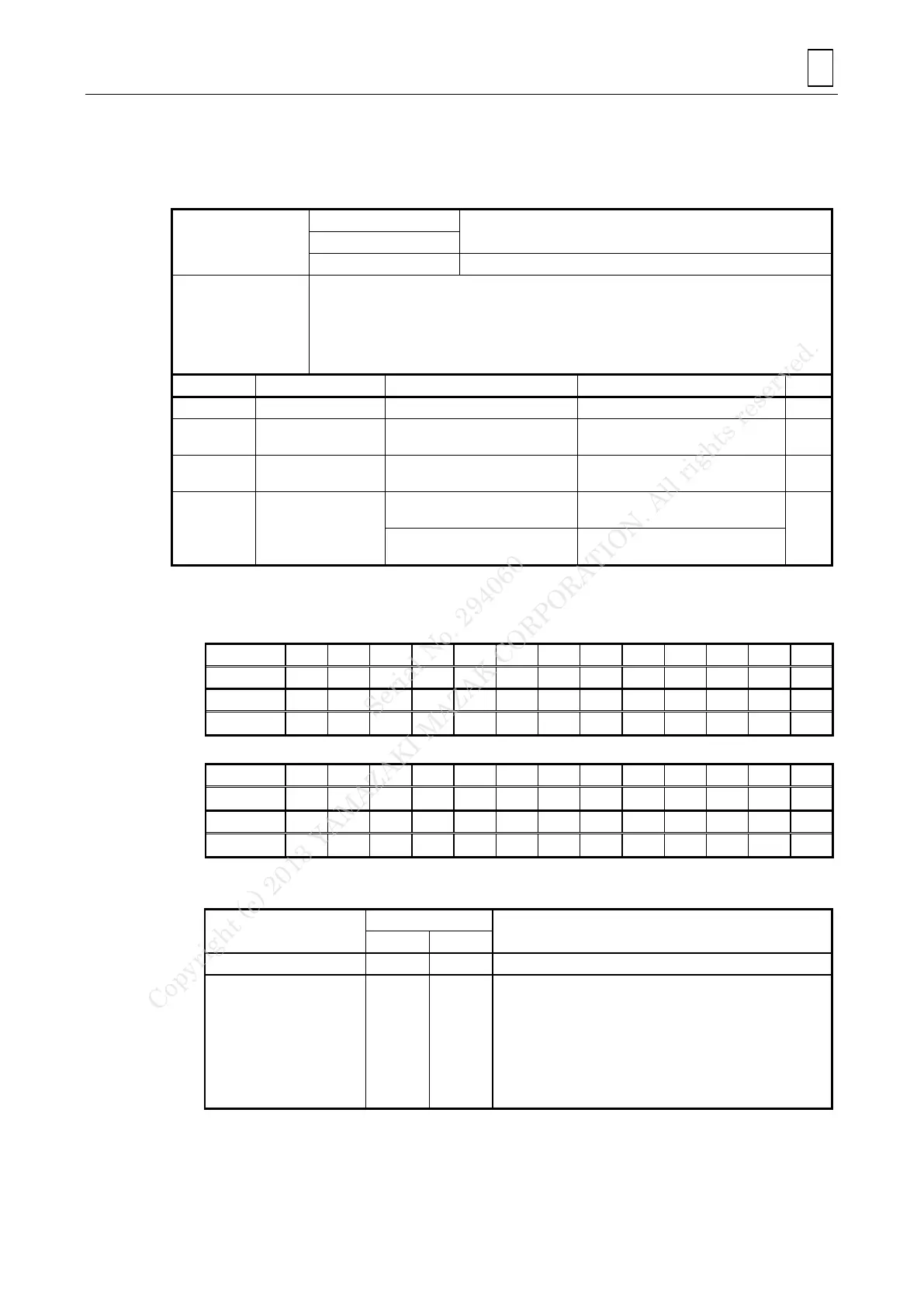

A. Tool function

1. Command

Tool change (with upper turret)

Tool change (with lower turret)

This function code mounts the specified tool in the spindle and returns the tool of the spindle

to the magazine or indexing turret. If the next tool is also specified, it will be set on the tool

carrier as the stand-by tool to be used next.

When MAZATROL tool data is validated (Note 2), tool length offsetting will be performed

according to the MAZATROL tool data LENGTH that corresponds to the designated tool

number.

Number of the tool

to be changed for

Tool number. Tool ID code

(Note 1)

[Tool number] 00 to Tool quantity

[Tool ID code] 00 to 26, 61 to 86

Number of the tool

to be used next

Tool number. Tool ID code

(Note 1)

[Tool number] 00 to Tool quantity

[Tool ID code] 00 to 26, 61 to 86

Number of the tool

to be changed for

(Note 3)

Tool number 000. Tool ID code

(Note 1)

[Tool number] 001 to Tool quantity

[Tool ID code] 00 to 26, 61 to 86

Tool number 00. Tool ID code

(Note 1)

[Tool number] 01 to Tool quantity

[Tool ID code] 00 to 26, 61 to 86

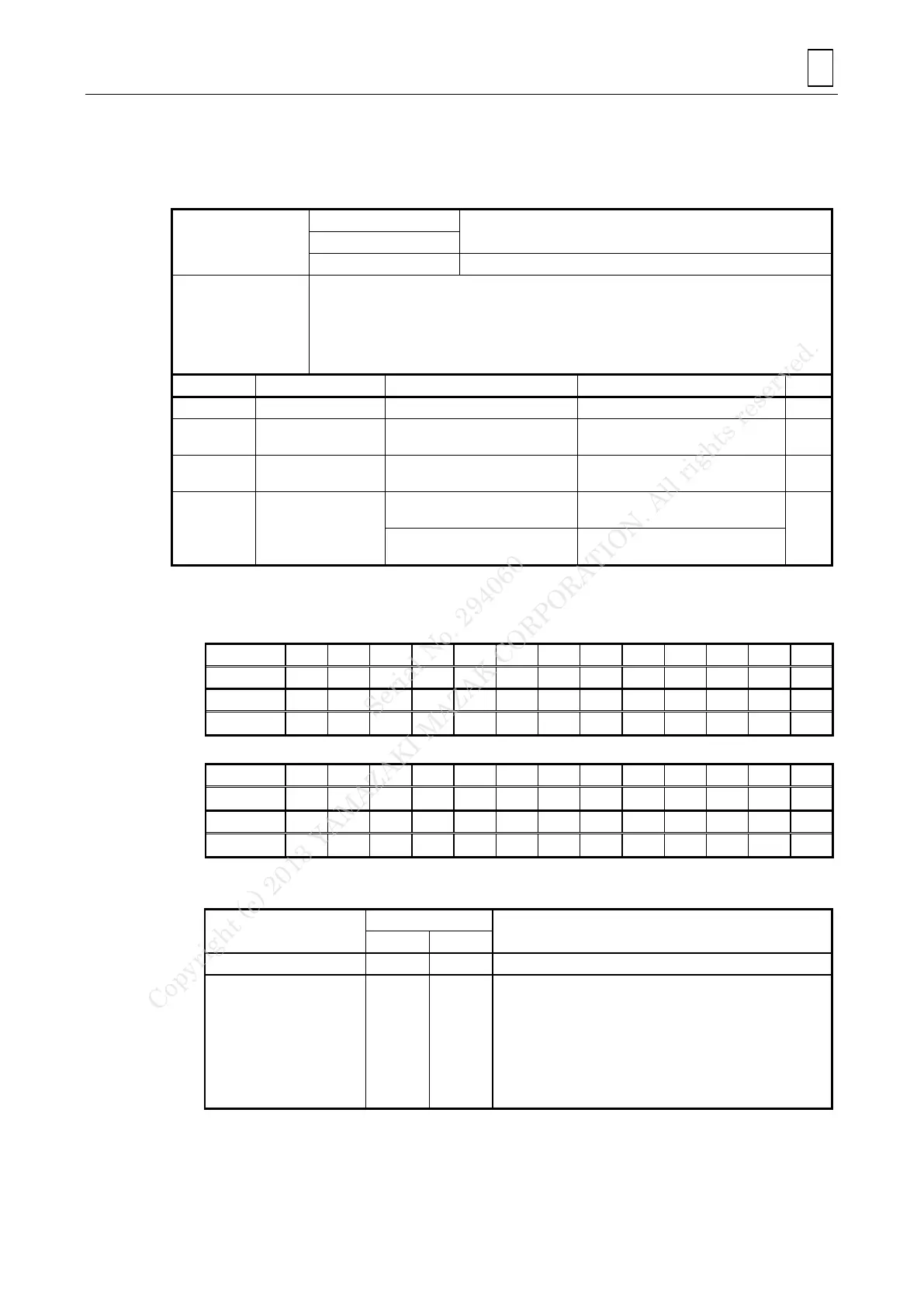

Note 1: Use two digits after the decimal point as follows to designate the tool ID code with

reference to the settings on the TOOL DATA display.

<Normal tools>

<Heavy tools>

Note 2: It depends on the setting of F93 bit3 and F94 bit7 whether TOOL OFFSET or

MAZATROL TOOL DATA is selected.

How and when the MAZATROL TOOL DATA actually

takes place

[For milling tools]:

Length offsetting in the first movement on the Z-axis.

[For turning tools]:

Offsetting by LENGTH A in the first movement on the

Z-axis, and by LENGTH B in the first movement on the

X-axis.

Serial No. 294060

Copyright (c) 2013 YAMAZAKI MAZAK CORPORATION. All rights reserved.

Loading...

Loading...