3. Operation

3.

Pour cooling water slowly into the fresh

water tank so that air

bubbles

do

not

develop. Supply until the water over-

flows from the filler port.

If the filler cap

is

loose, hot steam and

water will spout out

which may cause

burns.

4. After supplying cooling water, replace

filler

cap and tighten it firmly. Failure to

do

so will cause water leakage. To re-

place the cap, align the detents on the

bottom

of

the cap with the notches on

the

filler port and turn clockwise %

of

a

turn.

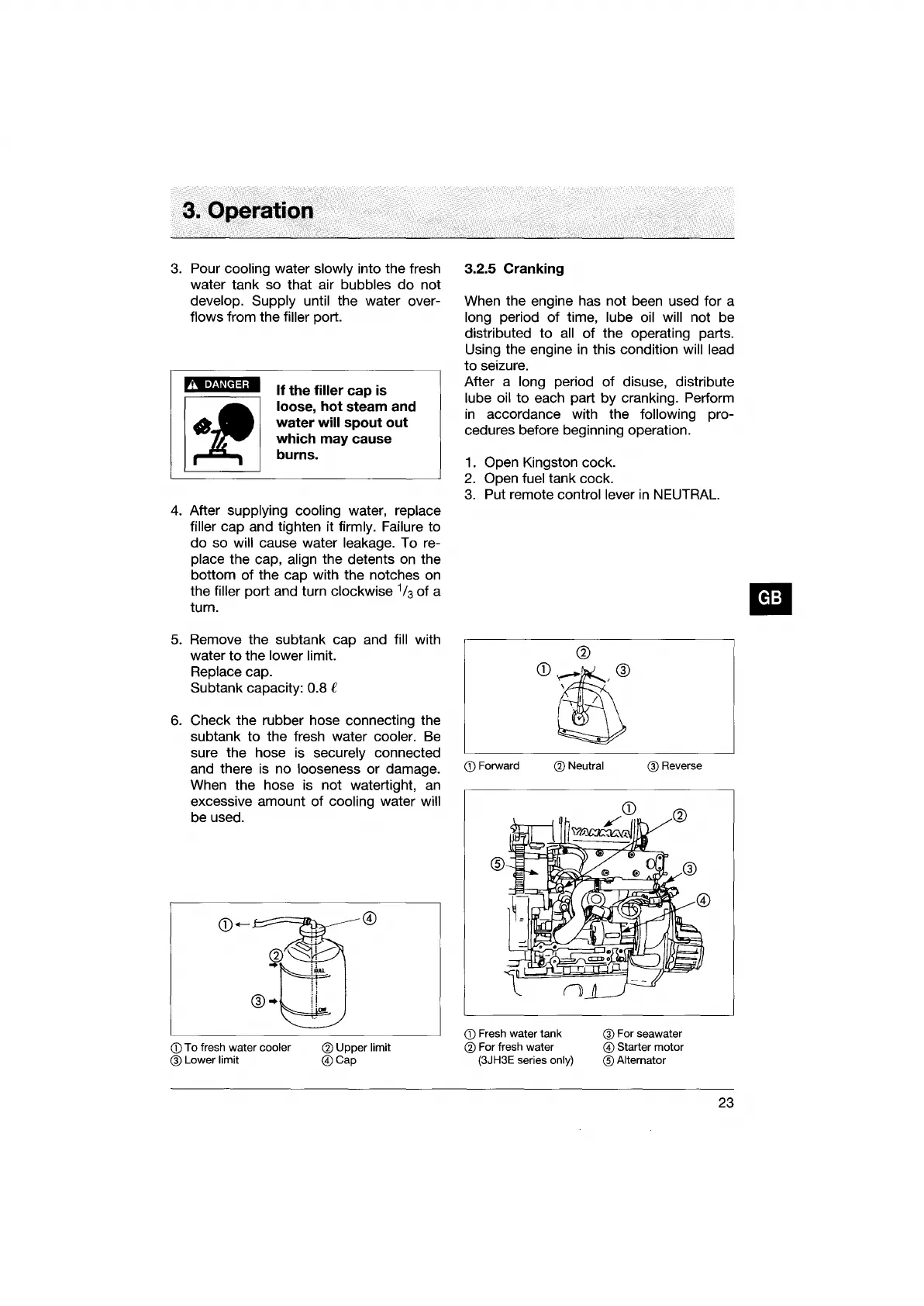

5.

Remove the subtank cap and fill with

water

to

the lower limit.

Replace

cap.

Subtank capacity:

0.8 e

6.

Check the rubber hose connecting the

subtank

to

the fresh water cooler. Be

sure the hose is

securely connected

3.2.5 Cranking

When the engine has not been used for a

long period

of

time, lube oil will not be

distributed

to

all

of

the operating parts.

Using the engine

in

this condition will lead

to

seizure.

After a

long period

of

disuse, distribute

lube oil

to

each part by cranking. Perform

in

accordance with the following pro-

cedures before beginning operation.

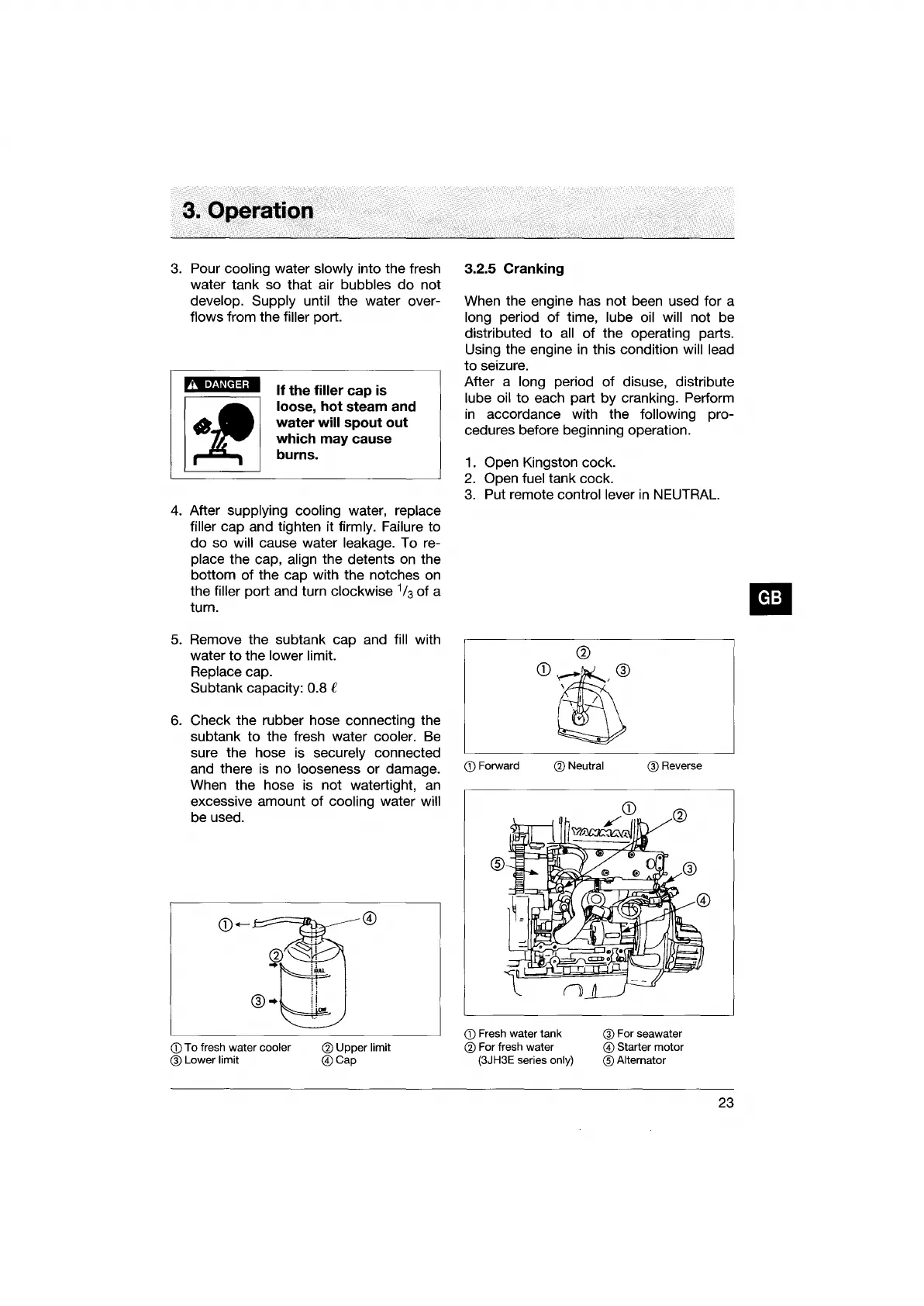

1.

Open Kingston cock.

2.

Open fuel tank cock.

3.

Put remote control lever

in

NEUTRAL.

@

0)~

...

,<d@

®

and there is no looseness or damage.

CD

Forward

@Neutral

® Reverse

When the hose is not watertight,

an

excessive amount

of

cooling water will

be used.

CD

To fresh water cooler

@ Lower limit

@

Upper limit

@:leap

®

CD

Fresh water tank

@ For fresh water

(3JH3E series

only)

® For seawater

@:l

Starter

motor

® Alternator

23

Loading...

Loading...