3. Operation

4.

Turn on the battery switch.

5. Insert the key into the key switch and

turn the key

to

ON. If the alarm buzzer

sounds and

alarm lamps come on, the

alarm devices are normal.

Note: The cooling water temp. warning

lamp does not come on.

(See

2.5.1.(3))

6.

Turn the key switch

to

start the engine.

Release the key switch when the en-

gine has started. The

alarm buzzer

should stop and the alarm lamps go

out.

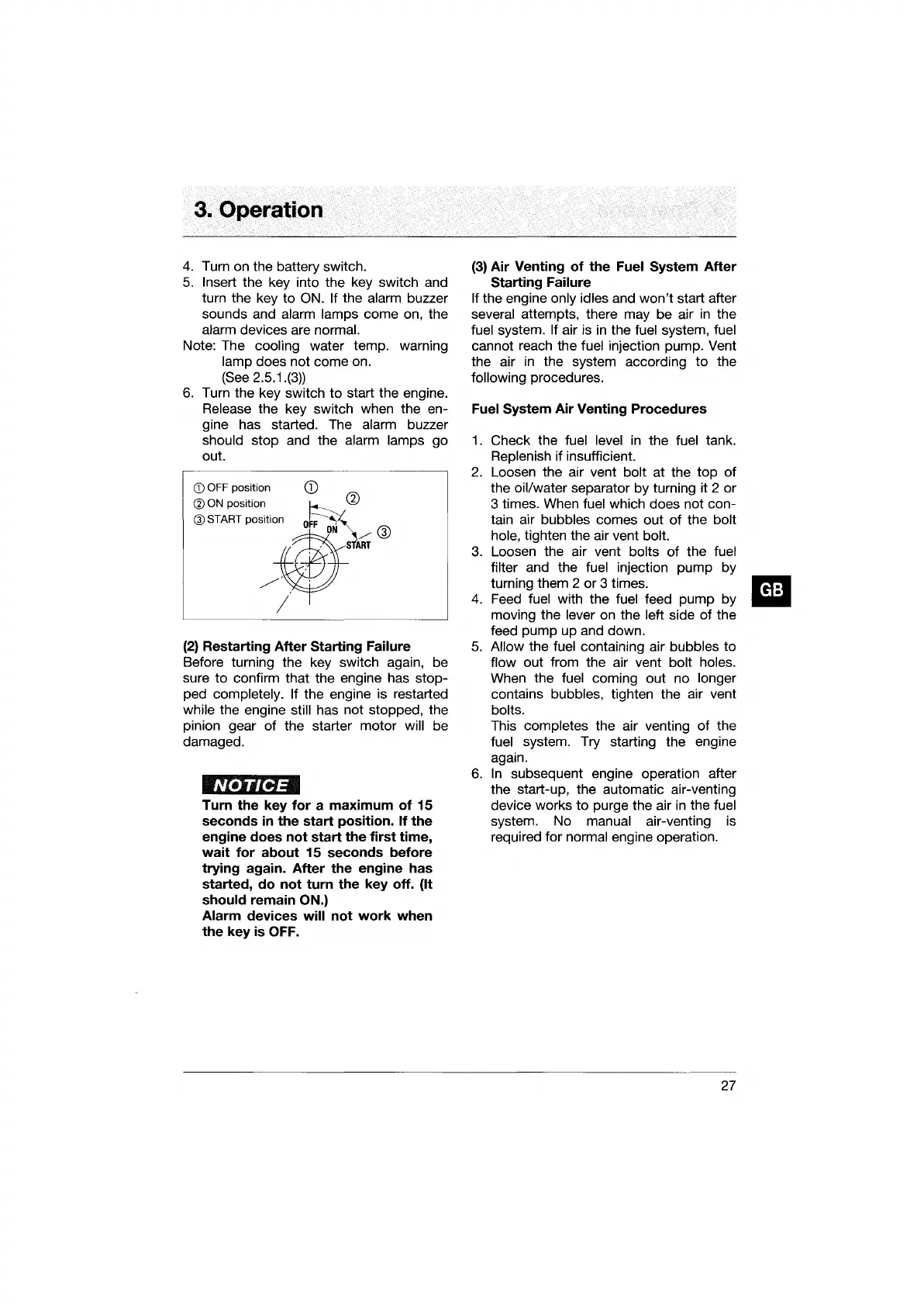

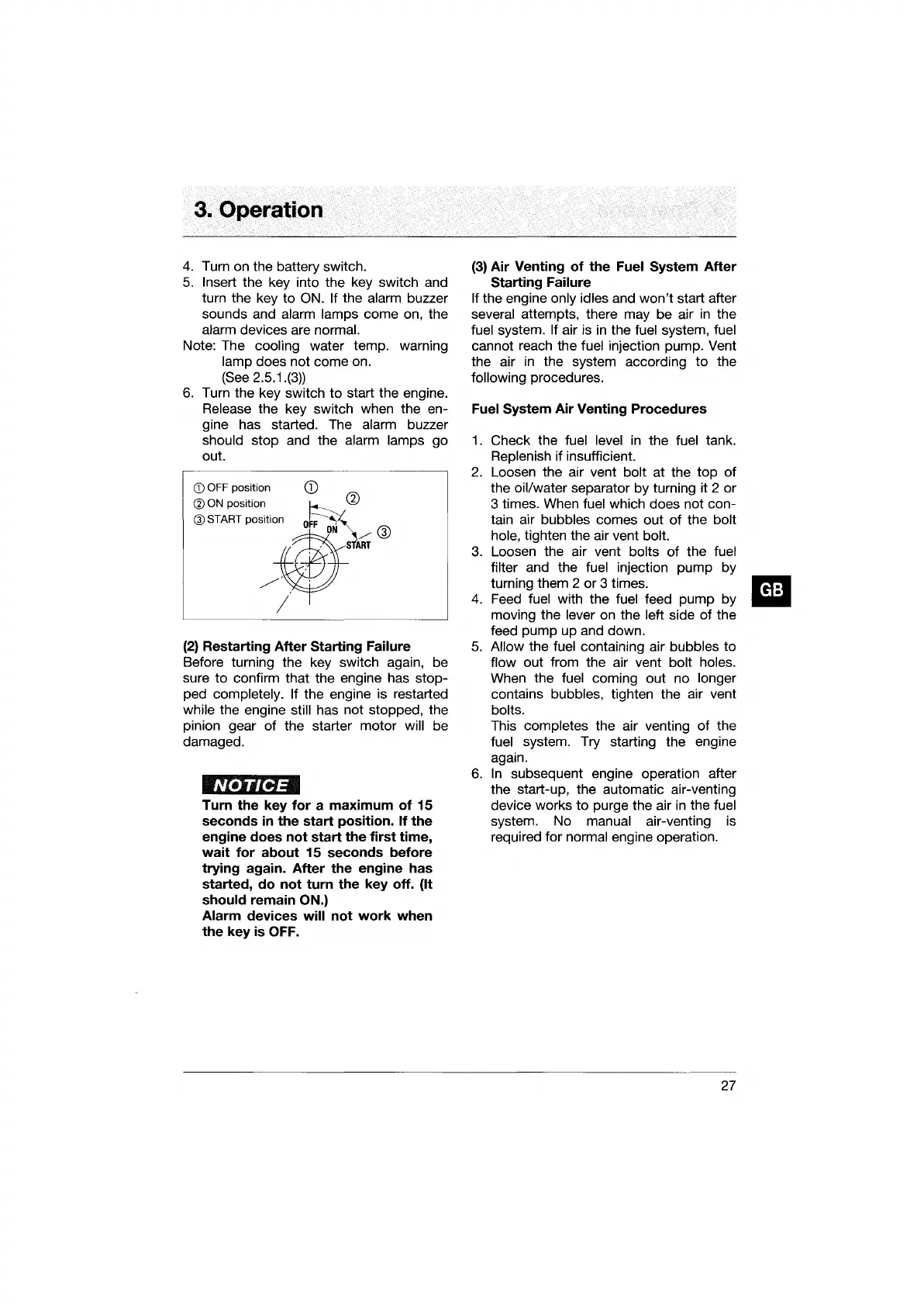

CD

OFF

position

CD

@ON

poo';oo

t~

®STARTPOSltIO~"

O~ ~

ST~

@

./'

'

/

(2)

Restarting After Starting Failure

Before turning the key switch again, be

sure

to

confirm that the engine has stop-

ped

completely. If the engine is restarted

while the engine still has not stopped, the

pinion gear of the starter motor

will be

damaged.

Turn the key for a maximum of 15

seconds

in

the start position. If the

engine does not start the first time,

wait for about 15 seconds before

trying again. After the engine has

started, do not turn the key off.

(It

should

remain ON.)

Alarm

devices will not work when

the key

is

OFF.

(3)

Air Venting of the Fuel System After

Starting

Failure

If

the engine only idles and

won't

start after

several attempts, there may be air

in

the

fuel system. If air is

in

the fuel system, fuel

cannot reach the fuel injection pump. Vent

the air

in

the system according

to

the

following procedures.

Fuel System Air Venting Procedures

1.

Check the fuel level

in

the fuel tank.

Replenish if insufficient.

2.

Loosen the air vent bolt at the

top

of

the oil/water separator by turning it 2 or

3 times. When

fuel which does not con-

tain air

bubbles comes out

of

the bolt

hole,

tighten the air vent bolt.

3.

Loosen the air vent bolts of the fuel

filter

and the fuel injection pump by

turning them 2 or 3 times .

4.

Feed fuel with the fuel feed pump by

moving the

lever on the left side of the

feed pump up and down.

5.

Allow the fuel containing air bubbles to

flow out from the air vent bolt holes.

When the fuel coming out no longer

contains bubbles, tighten the air vent

bolts.

This completes the air venting of the

fuel system. Try starting the engine

again.

6.

In

subsequent engine operation after

the start-up, the automatic air-venting

device works

to

purge the air

in

the fuel

system. No manual air-venting is

required for

normal engine operation.

27

Loading...

Loading...