YASKAWA TM.iQp.02 iQpump Drive Programming Manual 193

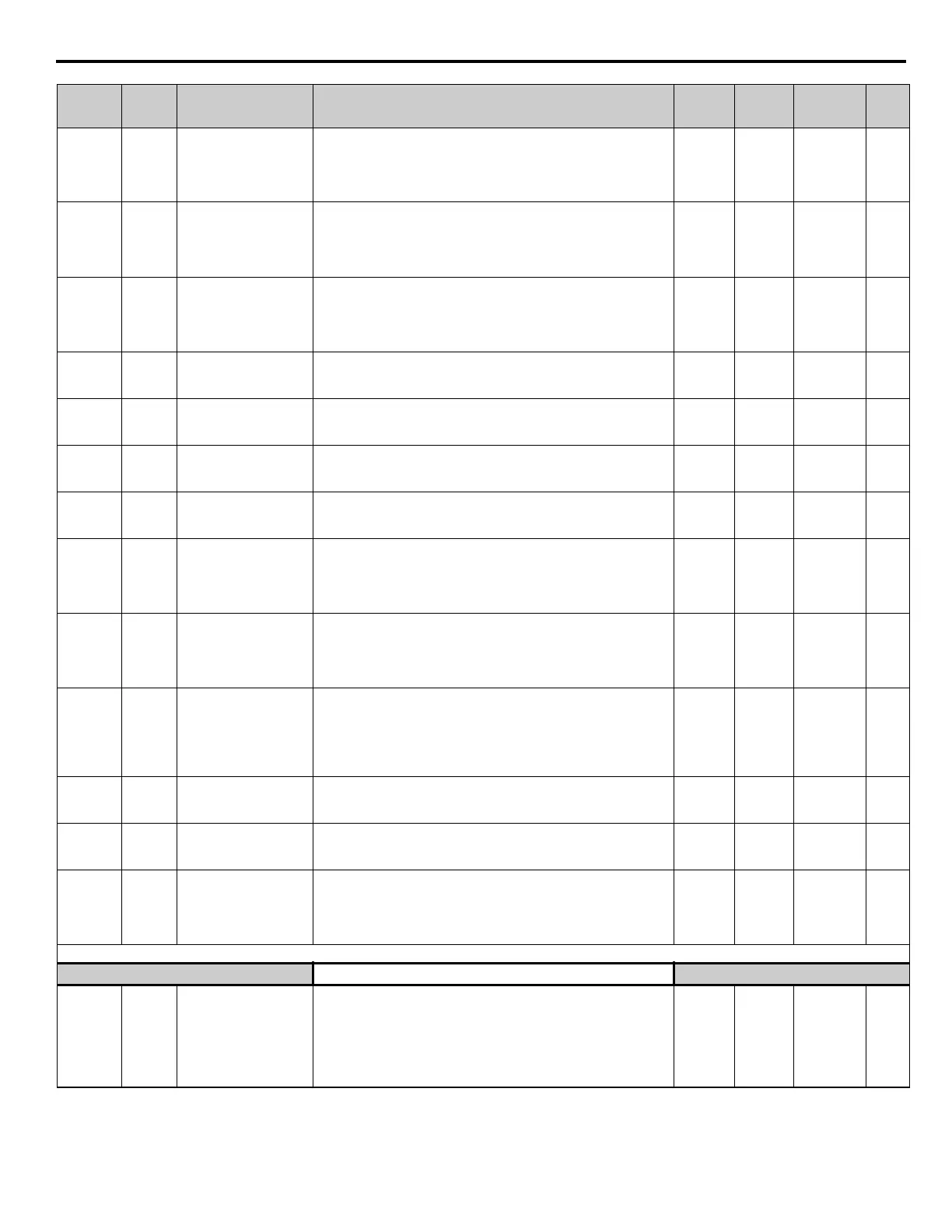

P2-08 0611H

Over Cycling Mode

Over Cycle Mode

Sets the Over Cycle Mode:

0: Disabled

1: Alarm

2: Pump Over Cycle Fault (POC)

3: Auto Compensation

0 to 3 0 Programming

135

P2-09 0612H

Setpoint compensation

Setpoint Comp.

Allows for the software to automatically compensate the setpoint in

case of excessive cycling.

0.0 to

6000.0

(system

units P1-

02)

0.0

(system

units P1-

02)

Programming

136

P2-10 0613H

Maximum Setpoint

compensation

Max. SP Comp.

Maximum allowable setpoint compensation for the over-cycling

function.

0.0 to

6000.0

(system

units P1-

02)

0.0

(system

units P1-

02)

Pump Quick

Setup

136

P2-11 010BH

No-Flow Activation

Level

NF Act. Level

When the motor RPM falls below the programmed level in P2-12, the

no-flow detection will activate. A value of 0 disables this function.

0 to 24000 0 RPM Programming

136

P2-12 010CH

No-Flow Detection

Bandwidth

NF Det.Bandwidth

Sets the motor RPM fluctuation bandwidth. No-flow activates when

the motor RPM remains within the programmed bandwidth in P2-12

for a time specified in parameter P2-13.

0 to 1000 15 RPM Programming

139

P2-13 010DH

No-Flow Detection Time

NF Detect Time

No-flow activates when the motor RPM remains within the

programmed bandwidth (P2-12) for a time specified in parameter P2-

13.

0.0 to

1000.0

5.0 sec Programming

139

P2-14 010EH

No-Flow Stabilization

Time

NF StabilizeTime

Time delay when setpoint returns to the original setting after being

changed for no-flow detection.

0.0 to

1000.0

5.0 sec Programming

139

P2-15 010FH

No-Flow Delta Feedback

Level

NF FB Level

No-flow feedback (PID-Error: setpoint minus feedback) level used to

detect no-flow condition based on feedback value.

Delta feedback (setpoint minus feedback) has to exceed the

programmed level for the time programmed in P2-17 to detect a no-

flow condition.

0.0 to

6000.0

(system

units P1-

02)

1.0

(system

units P1-

02)

Programming

139

P2-16 011FH

No-Flow Setpoint

Compensation

NF SP Comp.

Setpoint compensation used in the no-flow detection function.

0.0 to

6000.0

(system

units P1-

02)

1.5

(system

units P1-

02)

Programming

140

P2-17 0120H

No-Flow Feedback Delay

Time

NF FB.Delay Time

Delay timer used in combination with the no-flow feedback (PID-

Error: setpoint minus feedback) level (P2-15) used to detect the no-

flow condition based on the feedback value.

Delta feedback (Setpoint minus feedback) has to exceed the

programmed level (P2-15) for the time programmed to detect a no-flow

condition.

0.0 to

1000.0

2.0 sec Programming

140

P2-18 0121H

No-Flow Motor RPM

Sample Time

NF RPM Sample Tm

No-flow detection motor RPM sample rate.

0.1 to

1000.0

2.0 sec Programming 140

P2-19 0122H

No-Flow Feedback

Detection Direction

NF FB Det.Direct

Direction of feedback detection upon return of no-flow detection.

0: Outside Bandwidth (P2-15)

1: Inside Bandwidth (P2-15)

0 or 1 0 Programming

140

P2-20

0123H

Alternative Sleep

Activate Level

SLP Act. Level

When P2-01 Sleep Level Type is set for 0 (Output Frequency), the

sleep function becomes active when the output frequency is greater or

equal to the level in P2-20. When programmed to 0, the sleep function

will become active above the P2-02 Sleep Level.

A value of 0 disables this function.

0.0 to

120.0

0.0 Hz Programming

141

Denotes that parameter can be changed when the Drive is running.

Pump Multiplex

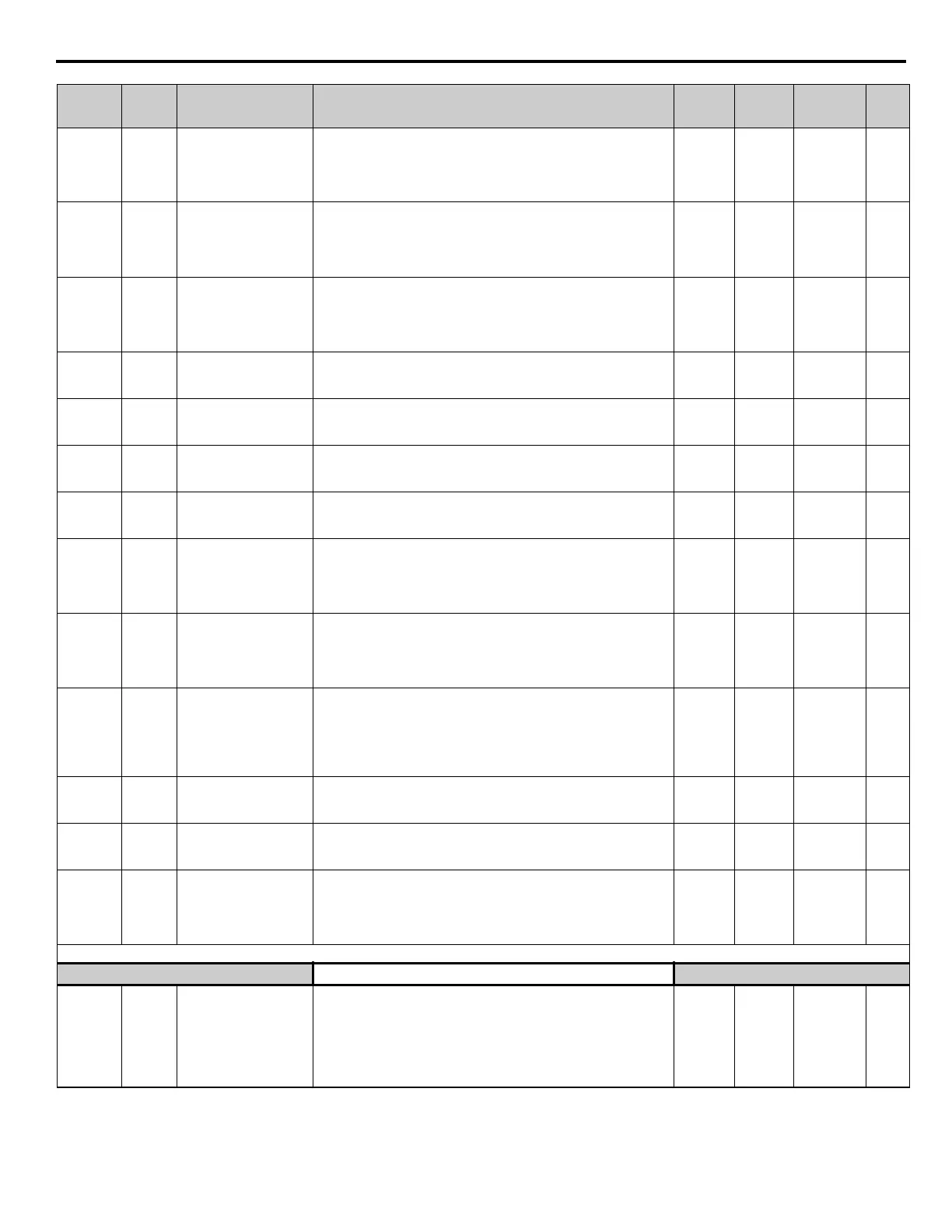

P3-01 0614H

Lead-Lag Control

Lead-Lag Control

Selects lead-lag detection operation.

0: Output Frequency (Output Frequency). 0: Uses P3-02, P3-04, P3-06,

P3-09, P3-10.

1: Feedback (Feedback Level). 1: Uses P3-03,P3-04,P3-05,P3-06.

2: Feedback + Fout (Feedback Level and Output Frequency). 2: Uses

P3-02,P3-03,P3-05,P3-06,P3-07, P3-08,P3-10.

Works in conjunction with parameters P2-11 to P2-19.

0 to 2 0 Programming

143

Parameter

No.

Modbus

Address

Parameter Name

Digital Operator

Display

Description

Setting

Range

Factory

Setting

Menu

Location

Page

No.

Loading...

Loading...