IM 12B07D02-01E

Troubleshooting 8-3

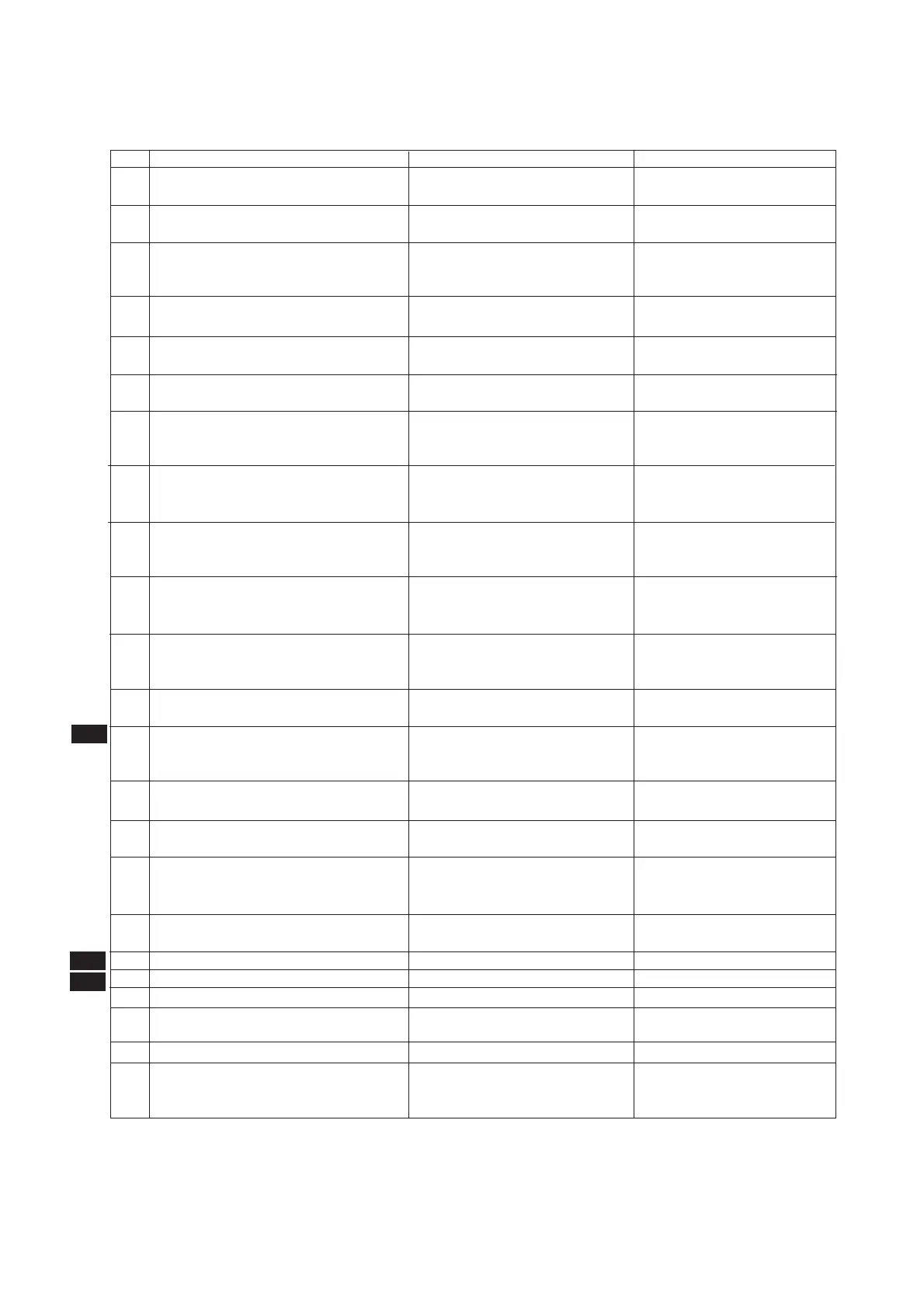

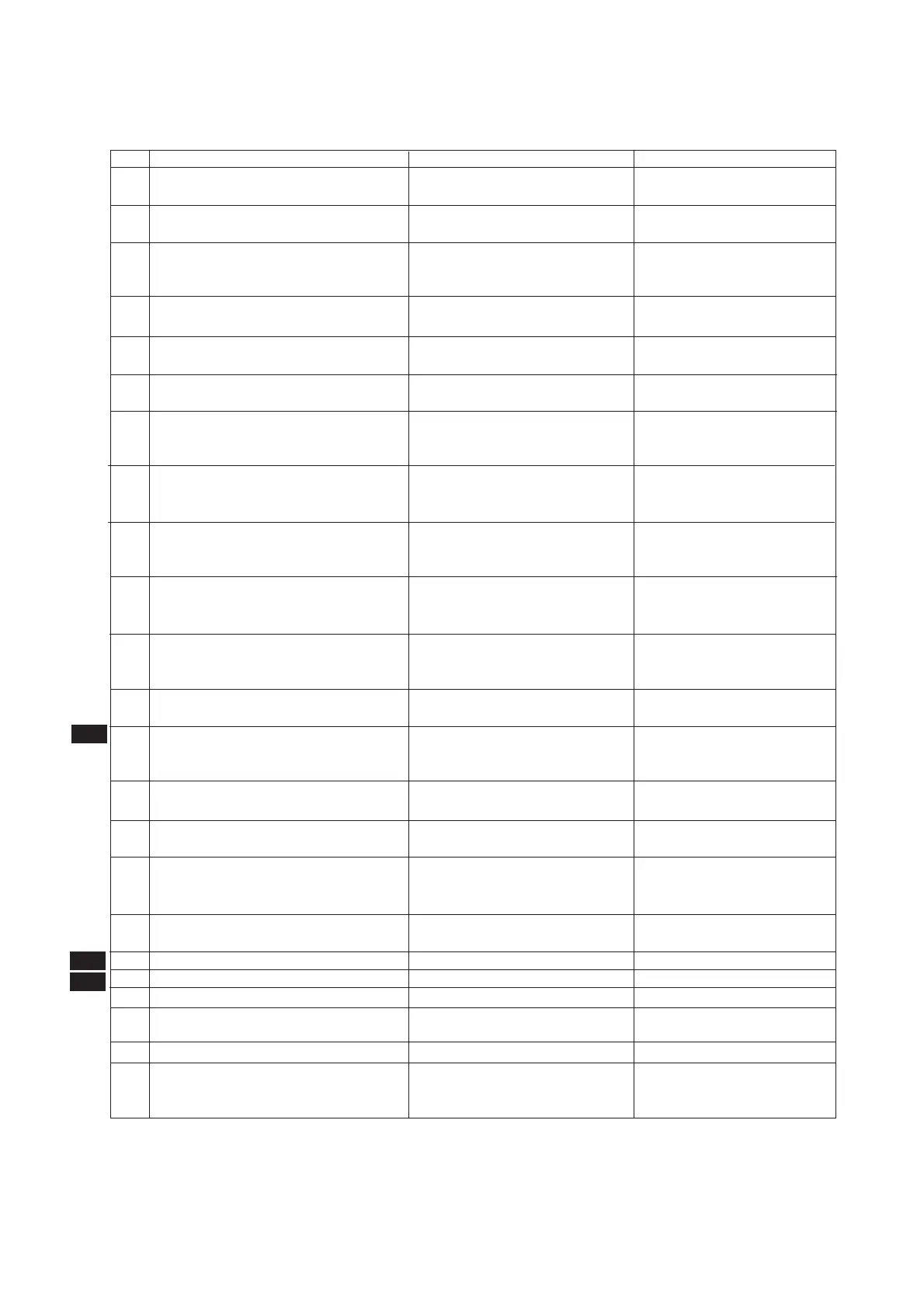

Table 8-1. Error Codes

Code Error description Possible cause Suggested remedy

E0 Buffer solution temperature Buffer solution too hot or too cold Adjust buffer temperature

outside the programmed range Check cabling

E1 Measurement failed to stabilize. Sensors fouled Clean sensors

during the calibration Sensors too slow (aged sensor) Replace sensors

E2 Asymmetry potential too high. Sensors are aged or polluted Check buffer solution

(Limits set in service code 21.) Mistake in calibration Recalibrate at pH7

Replace sensor

E3 Slope (sensitivity) is outside limits. Measuring sensor aged Replace measuring sensor

(Limits set in service code 22.) Poor insulation at the connector Replace or dry cables

E4.1 Impedance of input 1 too low. Measuring sensor broken Replace measuring sensor

(Limits set in service code 03.) Damaged or damp connections Replace or dry cable

E4.2 Impedance of input 2 too low. Reference sensor broken Replace reference sensor

(Limits set in service code 04.) Damaged connections Replace cables

E5.1 Impedance of input 1 too high. Measuring sensor disconnected Check connections

(Limits set in service code 03.) Sensors not immersed in process Check process

Liquid earth disconnected Check connections

E5.2 Impedance of input 2 too high. Reference sensor fouled Clean or replace sensor

(Limits set in service code 04.) Liquid earth disconnected Check sensor immersion

Insufficient electrolyte Check electrolyte reservoir

E7 Temperature sensor open Process too hot or too cold Check process

> 140°C (or <-10°C for 8k55) Wrong temperature sensor setting Check sensor & setting

Temperature sensor damaged Check connections

E8 Temperature sensor shortened Process too cold or too hot Check process

< -30 °C (or > 120 °C for 8k55) Wrong temperature sensor used Check sensor & setting

Temperature sensor damaged Check connections

E9 Measurement out of range (-2 to 16 pH) Sensors disconnected Check cabling

Sensor wrongly connected Check cabling

Sensor(s) defective Replace sensor(s)

E10 EEPROM write failure Fault in electronics Try again, if unsuccessful

contact Yokogawa

E11 Wash recovery check error Measuring sensor aged Replace measuring sensor

(if communication is set to pH201*B in code Sensor still coated after washing Check cleaning system

60) Defective wash system If needed adjust timings

E12 ORP / rH outside of preset limits Sensors disconnected or wrongly Check cabling

connected

E14 No valid calibration data. Data lost after switching from Recalibrate

pH to ORP

E15 Cable resistance to temperature Cable resistance too high Use Pt1000

sensor exceeds limit value. Corroded contacts Clean and reterminate

Wrong sensor programmed Reprogram

E16 Call for maintenance interval time exceeded. System not maintained in Perform maintenance

preset time period Reset interval

E17 Output span too small < 1pH Incorrect configuration by user Reprogram

E18 Table values make no sense

E19 Programmed values outside acceptable limits Incorrect configuration by user Reprogram

E20 All programmed data lost Fault in electronics Contact Yokogawa

Very severe interference

E21 Checksum error Software problem Contact Yokogawa

E23 Zero point outside limits Sensors are aged or polluted Check buffer solution

Mistake in calibration Recalibrate at pH7

Replace sensor

mA

mA

mA

Loading...

Loading...