YORK INTERNATIONAL

24

FORM 160.73-N1 (904)

springs are out of align ment, the misalignment must

be corrected by properly sup port ing the piping or by

ap ply ing heat to anneal the pipe.

If the piping is annealed to relieve

stress, the in side of the pipe must be

cleaned of scale be fore it is fi nal ly

bolt ed in place.

EVAPORATOR AND CONDENSER WATER PIPING

The evaporator and condenser liquid heads of chiller

have nozzles which are grooved, suitable for welding

150 PSIG DWP fl anges or the use of Victaulic cou plings.

Factory mount ed fl anges are optional.

The nozzles and water pass arrangements are fur nished

in accordance with the job requirements (see Product

Draw ings) furnished with the job. Standard units are

de signed for 150 PSIG DWP on the water side. If job

re quire ments are for greater than 150 PSIG DWP, check

the unit data plate before applying pressure to evap o ra tor

or con dens er to determine if the chiller has pro vi sions

for the required DWP.

Inlet and outlet connections are identifi ed by labels

placed adjacent to each nozzle.

Chilled Water

Foreign objects which could lodge in, or block fl ow

through, the evaporator and condenser tubes must be

kept out of the water circuit. All water piping must be

cleaned or fl ushed before being connected to the chiller

pumps, or other equipment.

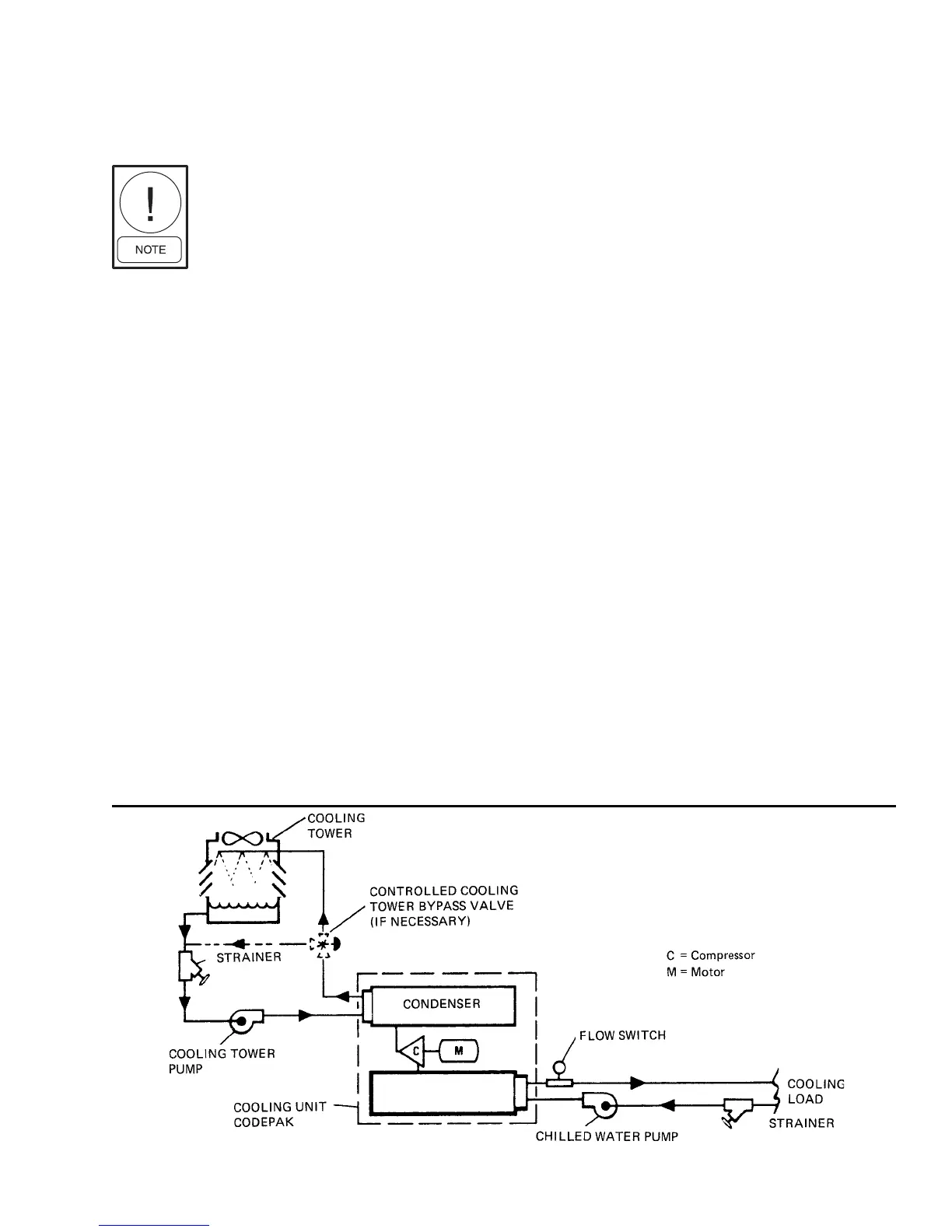

Permanent strainers (supplied by others) are re quired

in both the evaporator and condenser water circuits to

pro tect the chiller as well as the pumps, tower spray

noz zles, chilled water coils and controls, etc. The

strain er must be installed in the entering chilled water

line, di rect ly up stream of the chiller.

Water piping circuits should be arranged so that the

pumps discharge through the chiller, and should be

con trolled as necessary to maintain essentially constant

chilled and condenser water fl ows through the unit at

all load con di tions.

If pumps discharge through the chiller, the strainer may

be located upstream from pumps to protect both pump

and chiller. (Piping between strainer, pump and chiller

must be very carefully cleaned before start-up.) If pumps

are remotely installed from chiller, strainers should be

located directly upstream of the chiller.

Condenser Water Circuit

For proper operation of the unit, condenser refrigerant

pres sure must be maintained above evaporator pres sure.

If op er at ing con di tions will fulfi ll this requirement, no

at tempt should be made to control condenser water

tem per a ture by means of automatic valves, cycling of

the cooling tow er fan or other means, since chillers are

de signed to function satisfactorily and effi ciently when

con dens er water is al lowed to seek its own temperature

lev el at reduced loads and off-peak seasons of the year.

How ev er, if entering con dens er water temperature can

go be low the required min i mum, (refer to 160.73-O1)

con dens er water temperature must be maintained equal

to or slightly higher than the required minimum. Refer

to Fig. 13 for typical water pip ing schematic.

FIG. 13 – SCHEMATIC OF A TYPICAL PIPING ARRANGEMENT

LD08529

EVAP O RA TOR

Loading...

Loading...