YORK INTERNATIONAL

26

FORM 160.73-N1 (904)

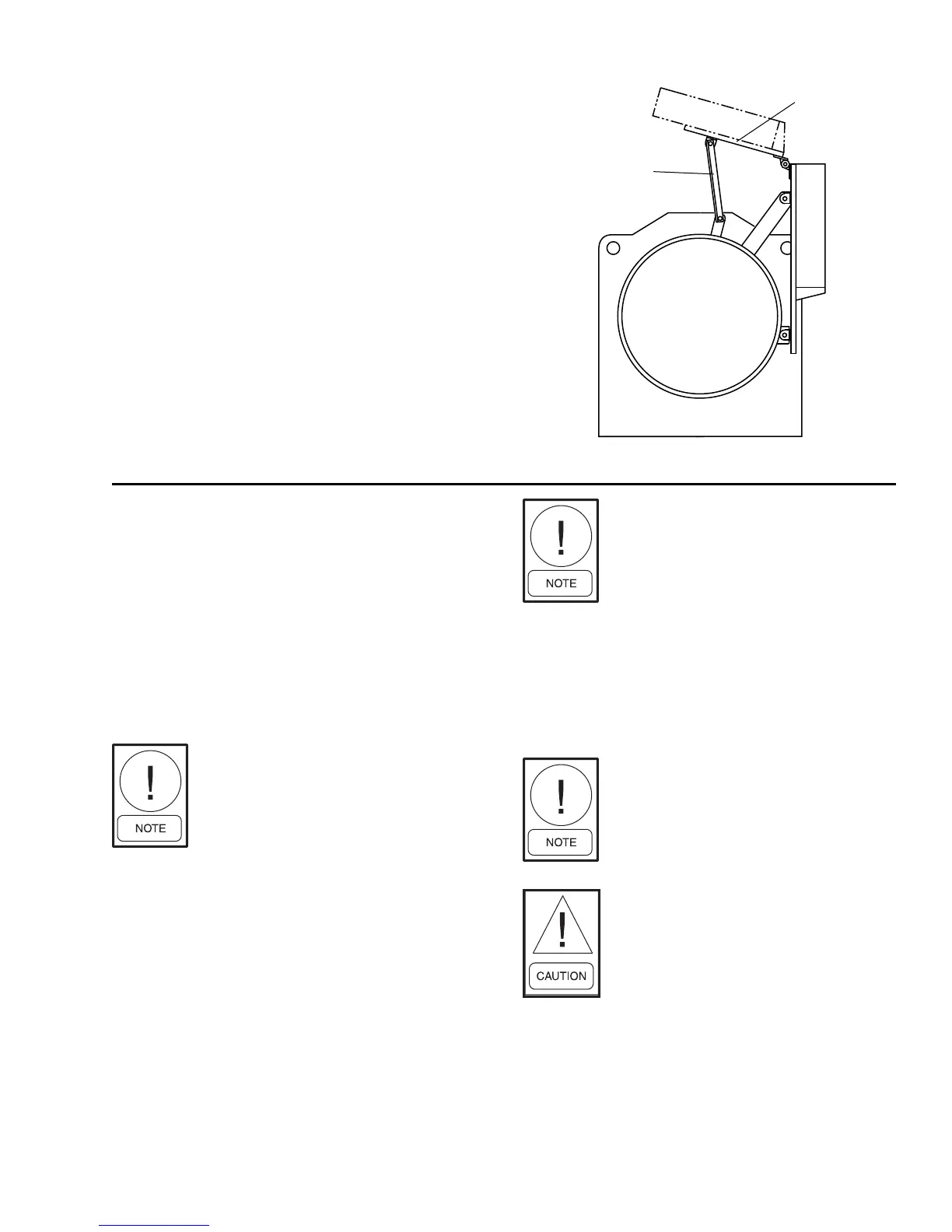

CONTROL PANEL POSITIONING (See Fig. 15)

On units with evaporator codes G thru X, the

OptiView™ Con trol Center is placed in a position above

the evaporator for shipping. To move the con trol center

into position for operation, pro ceed as follows:

1. While supporting the control center, remove

the hardware between the support arms and the

evap o ra tor.

2. Swing the control center into a vertical position.

3. Slide the control center down the guide rails to the

proper position. Tighten securely.

4. Discard unused hardware.

CONTROL WIRING

On units shipped disassembled, after in stal la tion of

the con trol center, control wiring must be completed

be tween unit com po nents and control center, solid state

starter, or vari able speed drive, when used, using wir ing

har ness fur nished. Refer to Form 160.73-N3.

Field wiring connections for commonly encountered

con trol modifi cations (by others) if required, are shown

on Form 160.73-PW4.

No deviations in unit wiring from that

shown on draw ings furnished shall be

made with out pri or ap prov al of the

YORK representative.

POWER WIRING

Chiller with Electro-Mechanical Starter

A 115 volt – single phase – 60 or 50 Hertz power sup ply

of 20 amperes must be fur nished to the control cen ter,

from the con trol trans form er (2 KVA required) in clud ed

with the com pres sor motor starter. DO NOT make fi nal

power con nec tions to con trol center until approved by

YORK rep re sen ta tive.

OIL PUMP – 3 PHASE STARTER

Separate wiring or a fused disconnect switch should be

sup plied by the installer.

SUPPORT

ARMS

PANEL

TRACK

FIG. 15 – CONTROL PANEL POSITIONING

Remote Electro-Mechanical starters

for the chill er must be furnished in ac-

cor dance with YORK Starter Specifi ca-

tions Product Draw ing Form 160.73-

PA1 to pro vide the fea tures nec es sary

for the start er to func tion prop er ly with

the YORK con trol system.

Each chiller unit is furnished for a specifi c electrical

pow er supply as stamped on the Unit Data Plate, which

also details the motor connection di a grams.

To in sure proper motor ro ta tion the

start er pow er in put and starter to mo-

tor con nec tions must be checked with

a phase se quence in di ca tor in the pres-

ence of the YORK rep re sen ta tive.

DO NOT cut wires to final length

or make fi nal con nec tions to motor

ter mi nals or start er power input ter-

mi nals until ap proved by the YORK

rep re sen ta tive.

YK Motors (Electro-Mechanical Starter)

Fig. 16 shows the power wiring hook-up for Motor

Con nec tions. (Refer to Wiring Labels in Motor Ter mi nal

Box for hook-up to suit motor voltage and am per age.)

Motor leads are furnished with a crimp type con nec tion

LD03826

Loading...

Loading...