FORM 160.73-N1 (904)

7

YORK INTERNATIONAL

NOTES:

1. All dimensions are approximate. Certifi ed dimensions are avail able on request.

2. For compact water boxes (shown above), determine overall unit length by adding water box depth to tube sheet length.

3. Water nozzles can be located on either end of unit. Add 13 mm (1/2 inch) to nozzle length for fl anges connections.

4. To determine overall height, add 22 mm (7/8 inch) for isolators.

5. Use of motors with motor hoods may increase overall unit di men sions.

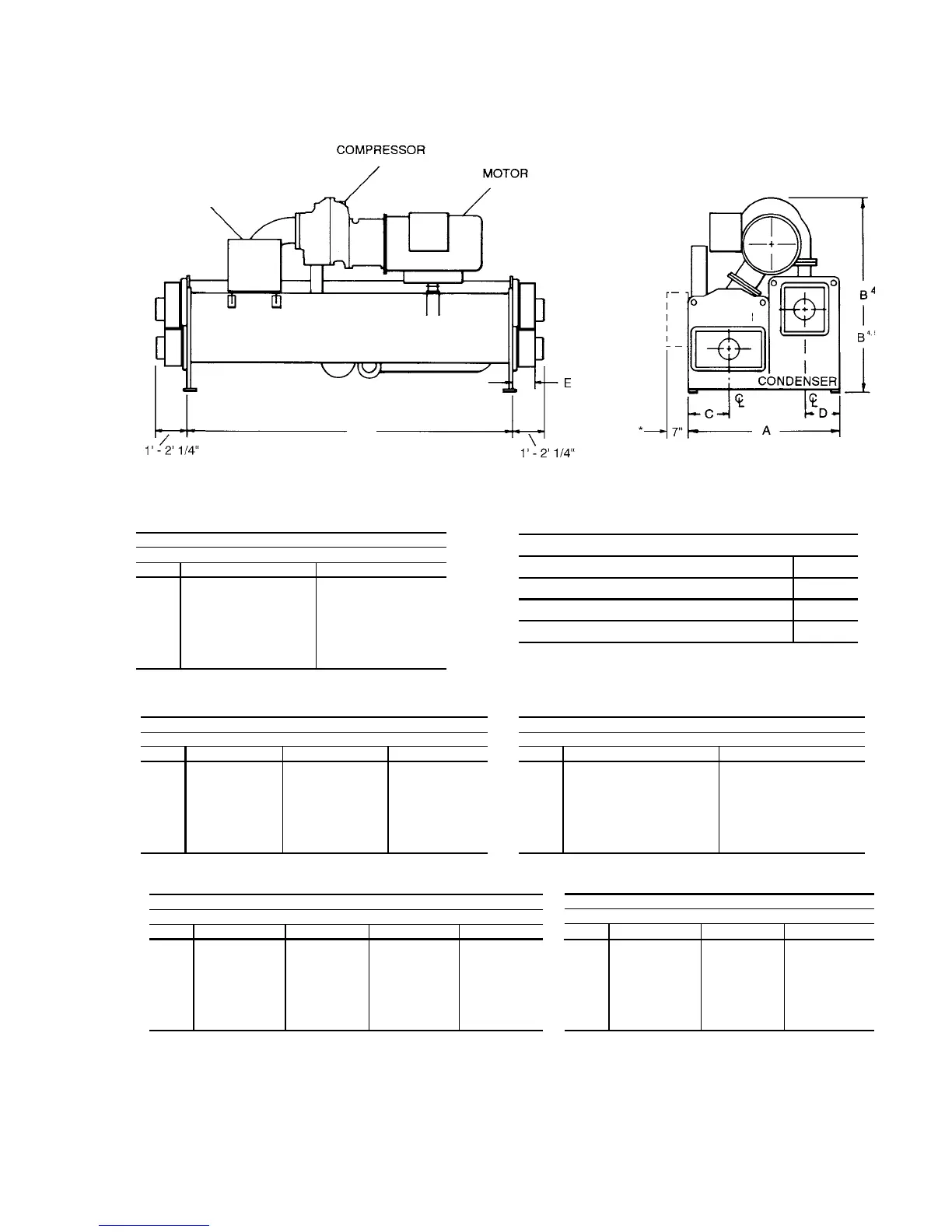

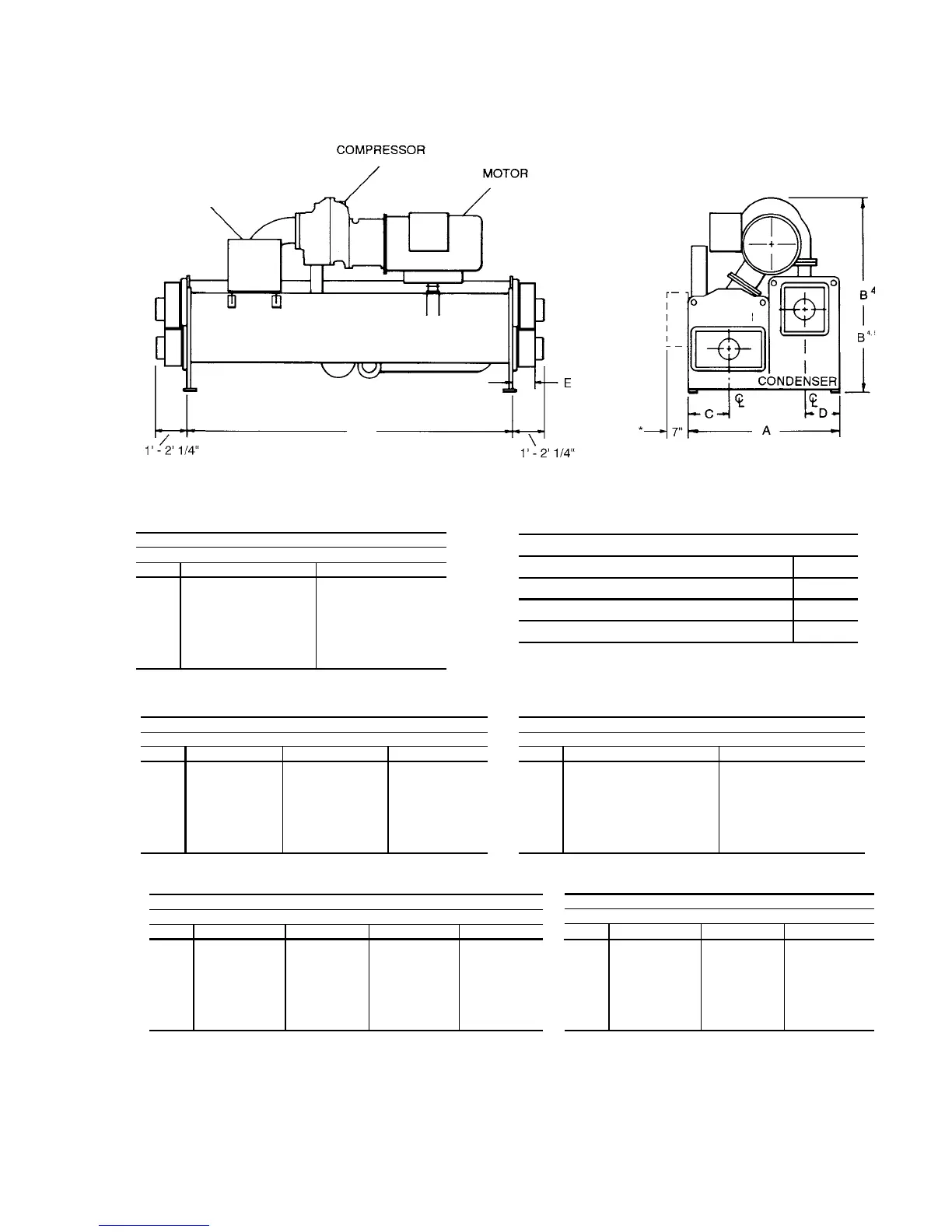

FIG. 3 – DIMENSIONS – P COMPRESSOR UNITS (mm)

LD03885

* Operating Location

of Control Center on

Evap o ra tor Codes G thru

W.

P COMPRESSOR UNITS

F

OPTIVIEW™

CONTROL

CENTER

EVAPORATOR

P8 COMPRESSOR

EVAPORATOR–CONDENSER SHELL CODES

E–E F–F G–G H–H

A 2,108 2,108 2,299 2,299

B 3,137 3,137 3,289 3,289

C 610 610 641 641

D 445 445 508 508

E 378 378 397 397

F 3,658 4,877 3,658 4,877

P9 COMPRESSOR

EVAPORATOR–CONDENSER SHELL CODES

F–F G–G H–H

A 2,108 2,299 2,299

B 3,045 3,200 3,200

C 610 641 641

D 445 508 508

E 378 379 397

F 4,877 3,658 4,877

P1, P2, P3, P4 COMPRESSORS

EVAPORATOR–CONDENSER SHELL CODES

A–A B–B

A 1,676 1,676

B 2,077 2,077

C 445 445

D 394 394

E 143 143

F 3,658 4,877

P5 COMPRESSOR

EVAPORATOR–CONDENSER SHELL CODES

A–A B–B C–C

A 1,676 1,676 1,880

B 2,248 2,248 2,299

C 445 445 495

D 394 394 445

E 143 143 143

F 3,658 4,877 3,658

P6, P7, Q7 COMPRESSOR

EVAPORATOR–CONDENSER SHELL CODES

C–C D–D

A 1,880 1,880

B 2,299 2,299

C 495 495

D 445 445

E 143 143

F 3,658 4,877

ADDITIONAL OPERATNG HEIGHT CLEARANCE

TYPE OF CHILLER MOUNTING M

NEOPRENE PAD ISOLATORS 44

SPRING ISOLATORS 25mm DEFLECTION 25

DIRECT MOUNT 19

Loading...

Loading...