JOHNSON CONTROLS

27

SECTION 3 - HANDLING, STORAGE, INSTALLATION AND REASSEMBLY

FORM 201.30-ICOM1 (519)

ISSUE DATE: 05/22/2019

3

MOVING THE CHILLER FOR FORMS 1 AND 2

Prior to moving the unit, make sure that the installa-

tion site is suitable for installing the unit and is easily

capable of supporting the weight of the unit and all as-

sociated services.

The unit is designed to be lifted using chains or cables.

The unit is provided with lifting eyes in the corners of the

end sheets, which can be attached directly using shackles

or safety hooks as shown in Figure 6 on page 28.

Improper Unit/Component Lift! Test

lift the unit/component approximately

24 in. (610 mm) to verify the proper

center of the gravity lift point. To avoid

dropping the unit/component, reposition

the lifting point if the unit/component

is not level. Failure to properly lift the

unit/component could result in death or

serious injury or possible equipment or

property-only damage.

RIGGING

The complete standard unit (Forms 1 and 2) is shipped

without skids. When optional skids are used, it may

be necessary to remove the skids so that the riggers

skates can be used under the unit end sheets to reduce

the overall height.

Each unit has provided lifting holes (two on each end

sheet), which should be used to lift the unit. Be care-

ful during rigging and handling to avoid damage to the

unit and its external connections. Lift only using the

holes specified.

The unit must be special ordered if it is necessary to

rig a unit on one end to permit lifting or dropping it

through a vertical passageway (e.g., an elevator shaft).

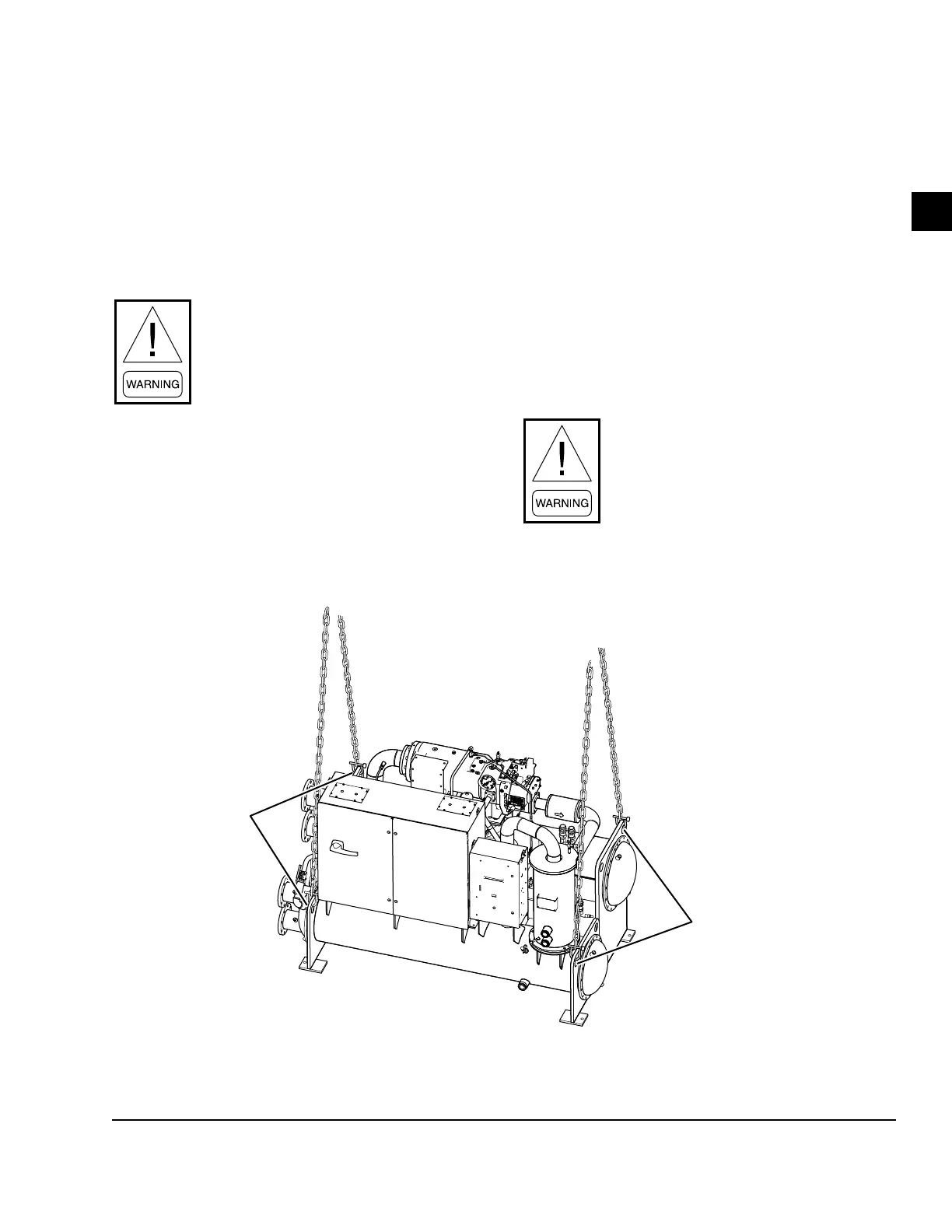

Never lift the entire unit with slings

around the compressor/motor assembly or

by the eyebolts in the tapped holes of the

compressor/motor assembly. Do not turn

the unit on its side for rigging or rig it

with the driveline in a vertical orientation.

FIGURE 7 - UNIT RIGGING FOR FORMS 1 AND 2

LD17277a

LIFTING

HOLES

LIFTING

HOLES

Loading...

Loading...