86

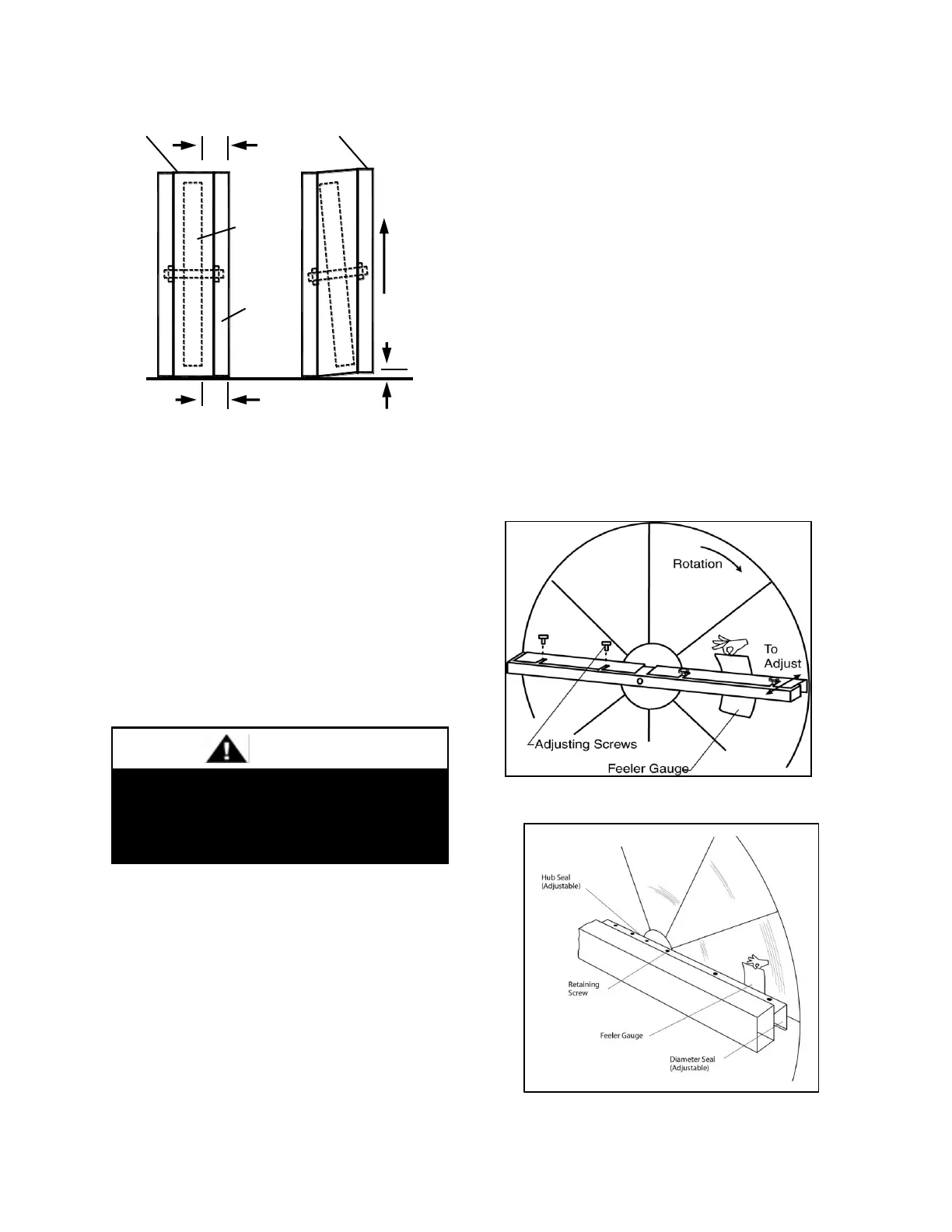

Avoid Racking of Cassette Frame

To verify, make certain that the distance

between wheel rim and bearing beam is the

same at each end of the bearing beam, to

within 1/4 of an inch (dimension A & B).

This amount of racking can be compensated

for by adjusting the diameter seals.

If greater than 1/4 inch (dimension C),

racking must be corrected to ensure that drive

belt will not disengage from wheel.

Polymer Wheel Startup Procedure

1. By hand, turn wheel clockwise (as

viewed from the pulley side), to verify

wheel turns freely through 360º rotation.

2. Before applying power to drive motor,

confirm wheel segments are fully

engaged in wheel frame and segment

retainers are completely fastened. (See

Segment Installation Diagram).

3. With hands and objects away from

moving parts, activate unit and confirm

wheel rotation. Wheel rotates clockwise

(as viewed from the pulley side).

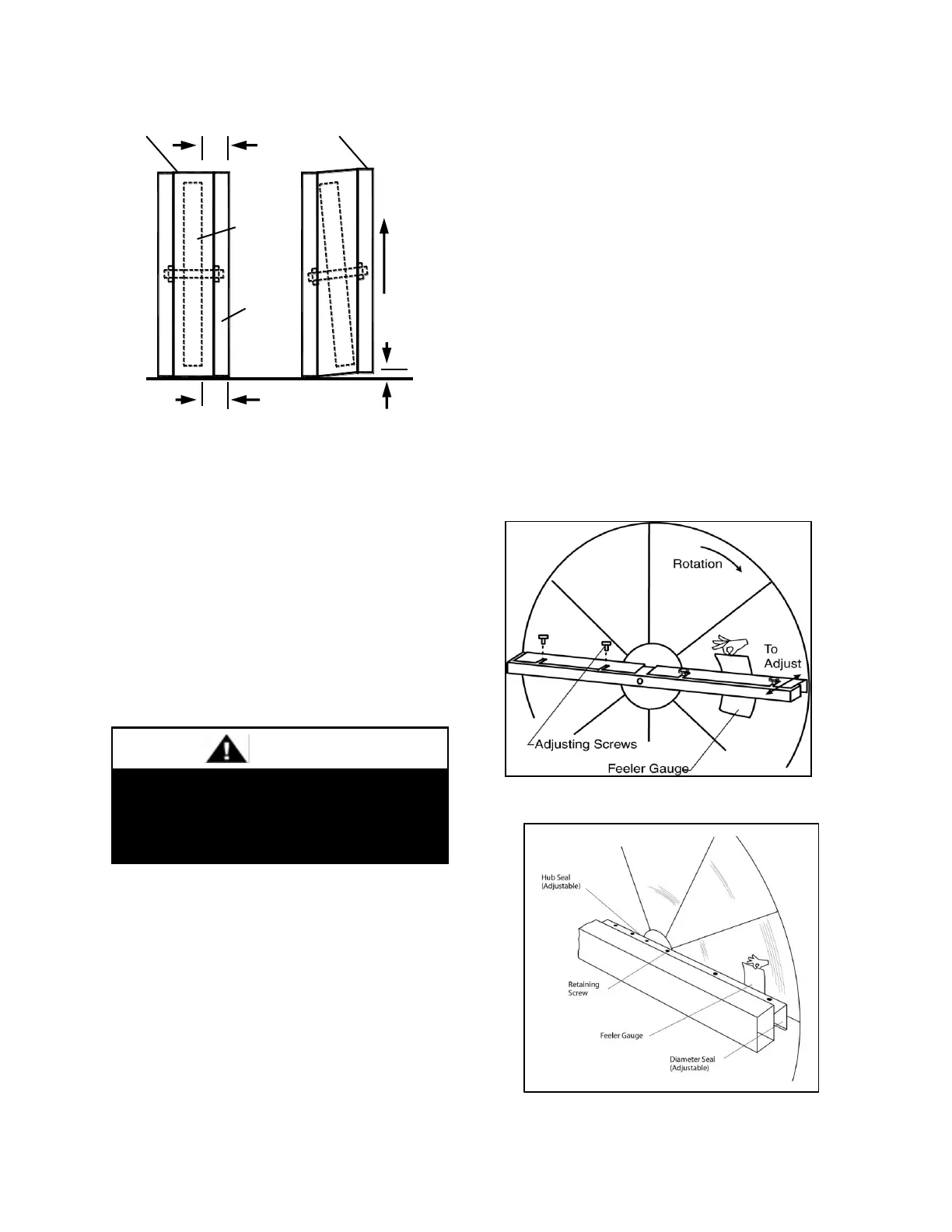

4. If wheel has difficulty starting, turn

power off and inspect for excessive

interference between the wheel surface

and each of the four (4) diameter seals.

To correct, loosen diameter seal

adjusting screws and back adjustable

diameter seals away from surface of

wheel, apply power to confirm wheel is

free to rotate, then re-adjust and tighten

hub and diameter seals, as shown in hub

seal adjustment diagram.

5. Start and stop wheel several times to

confirm seal adjustment and to confirm

belt is tracking properly on wheel rim

(approximately 1/4” from outer edge of

rim).

Diameter Seal Adjustment

Hub Seal Adjustment

Loading...

Loading...