90

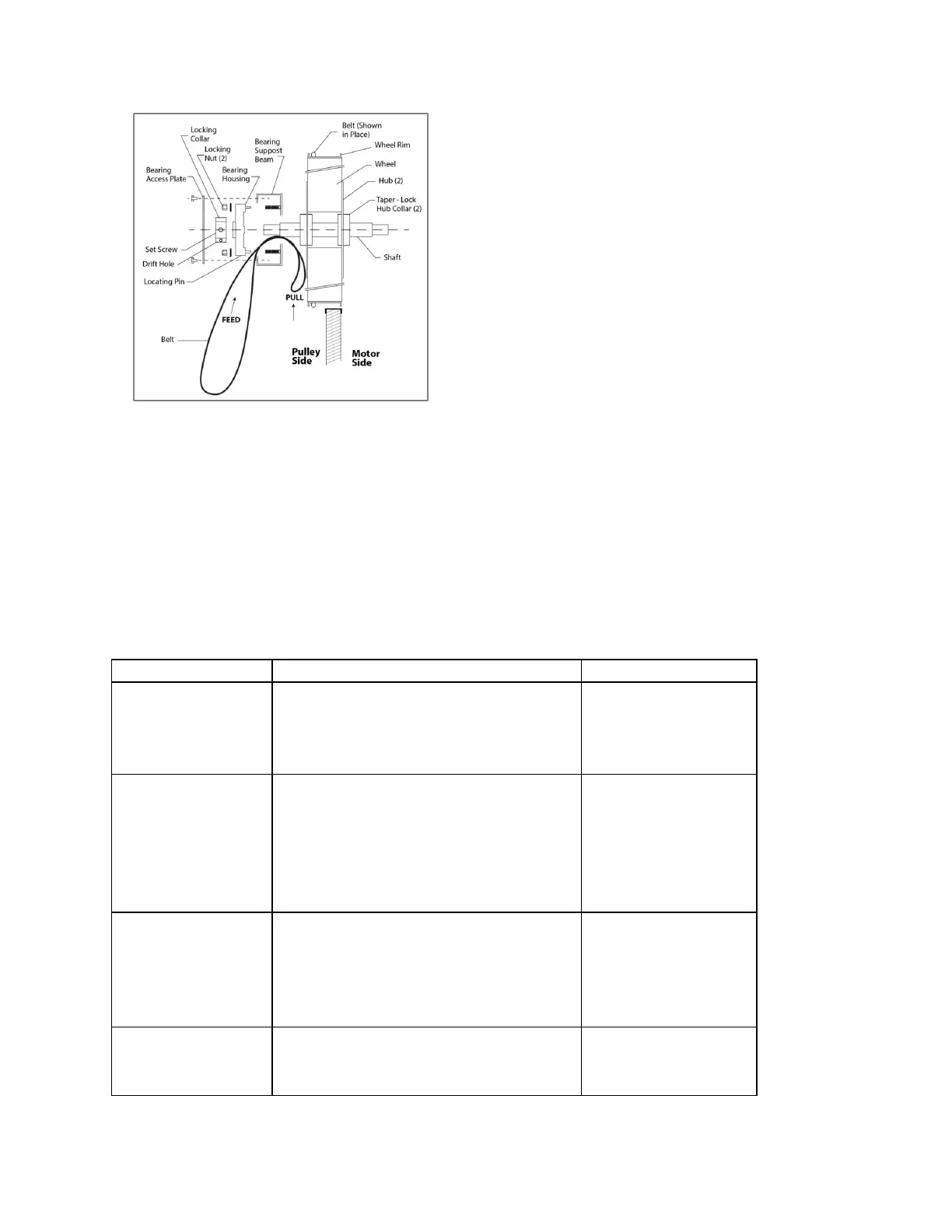

Belt Replacement

Energy Recovery Wheel General Cleaning

Routine maintenance of the Energy Recovery

Wheel includes periodic cleaning of the

Energy Recovery Wheel as well as inspection

of the Air Seals and Wheel Drive

Components.

Cleaning the energy transfer media will help

maintain optimal performance. The

frequency of cleaning is largely dependent on

the application and air quality. Use

ASHRAE’s Classes of Air categories, to

create a routine cleaning schedule.

Class 1 air has low contaminant

concentration with inoffensive odor and

sensory irritation intensity.

Class 2 air has moderate contaminant

concentration, with mildly offensive odors or

sensory-irritation intensity.

Class 3 air has significant contaminant

concentration and significant offensive odor

or sensory-irritation intensity.

Class 4 air has highly objectionable fumes or

gases and potentially contains dangerous

particles, bio-aerosols, or gases at a

concentration high enough to be considered

harmful, not suitable for recirculation or

transfer to any other space.

Table 26 - Energy Recovery Wheel Cleaning Frequency

Loading...

Loading...