Operation Manual / A170-M.. - A175-M..

9 Disassembly and assembly / 9.10 Fitting the spinner nose cone

© Copyright 2022 ABB. All rights reserved. HZTL4033_EN Rev.K January 2022

3. Coat the outer contact surface(A) between the spinner nose cone and the compressor

wheel over its entire circumference with Molykote® TP42.

4. Apply Loctite® 542 to the inner thread of the threaded stud.

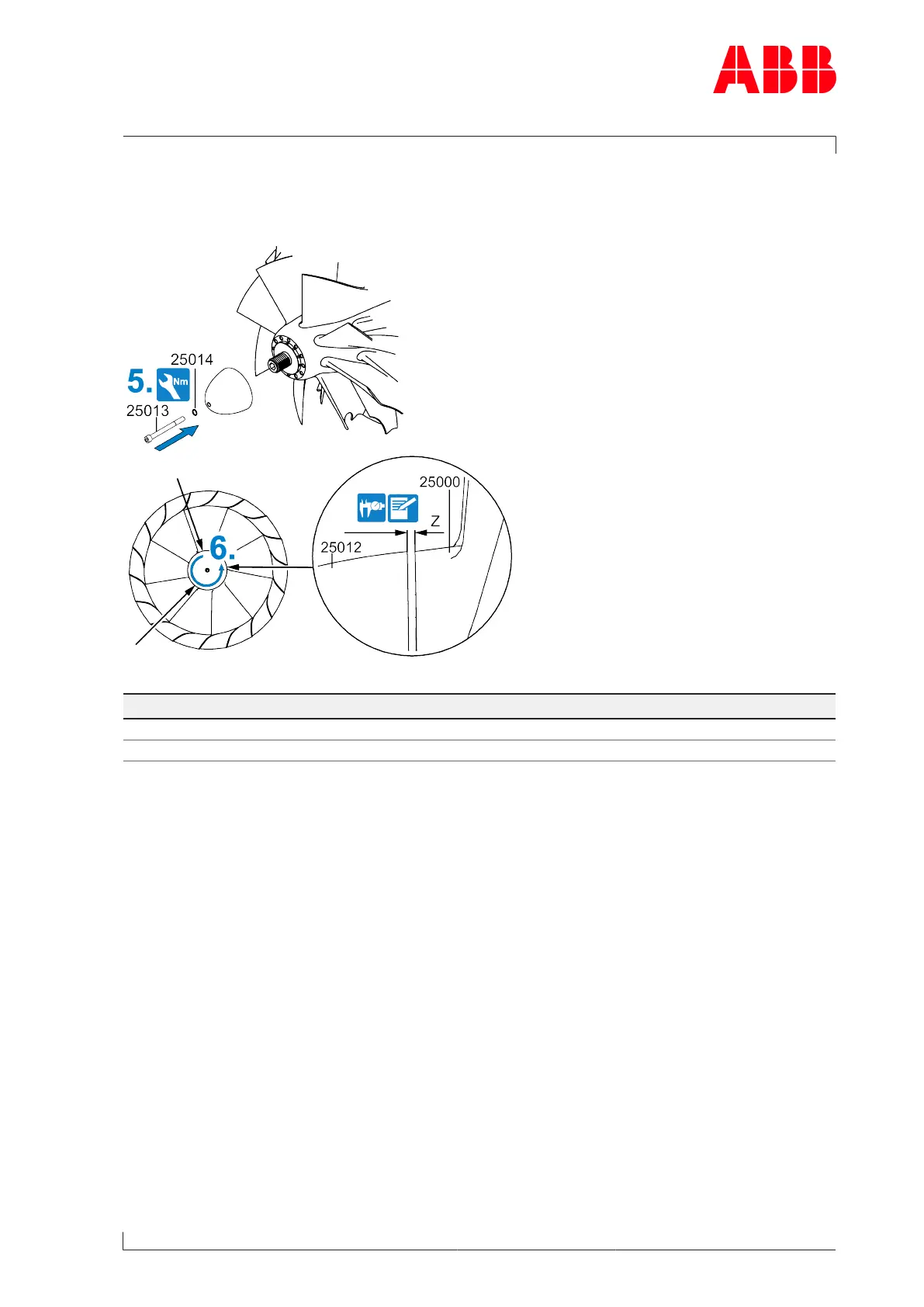

Fig.59: Fitting the spinner nose cone(25012)

Product Size Tightening torque [Nm]

A170-M M8 20

A175-M M10 40

Table43: Tightening torque (25013)

Always use a new socket screw (25013) and washer (25014) from the customer spare part set

(97070).

5. Fit the spinner nose cone and secure with washer (25014) and socket screw(25013). Ob-

serve tightening torque. The following must be taken into account:

u The tightening torque must be applied by two people. One person tightens socket

screw(25013), while the second person holds the compressor wheel (25000).

u Apply tightening torque constantly, avoid jerky movements. Observe tightening torque.

u Do not repeat the tightening of socket screw(25013).

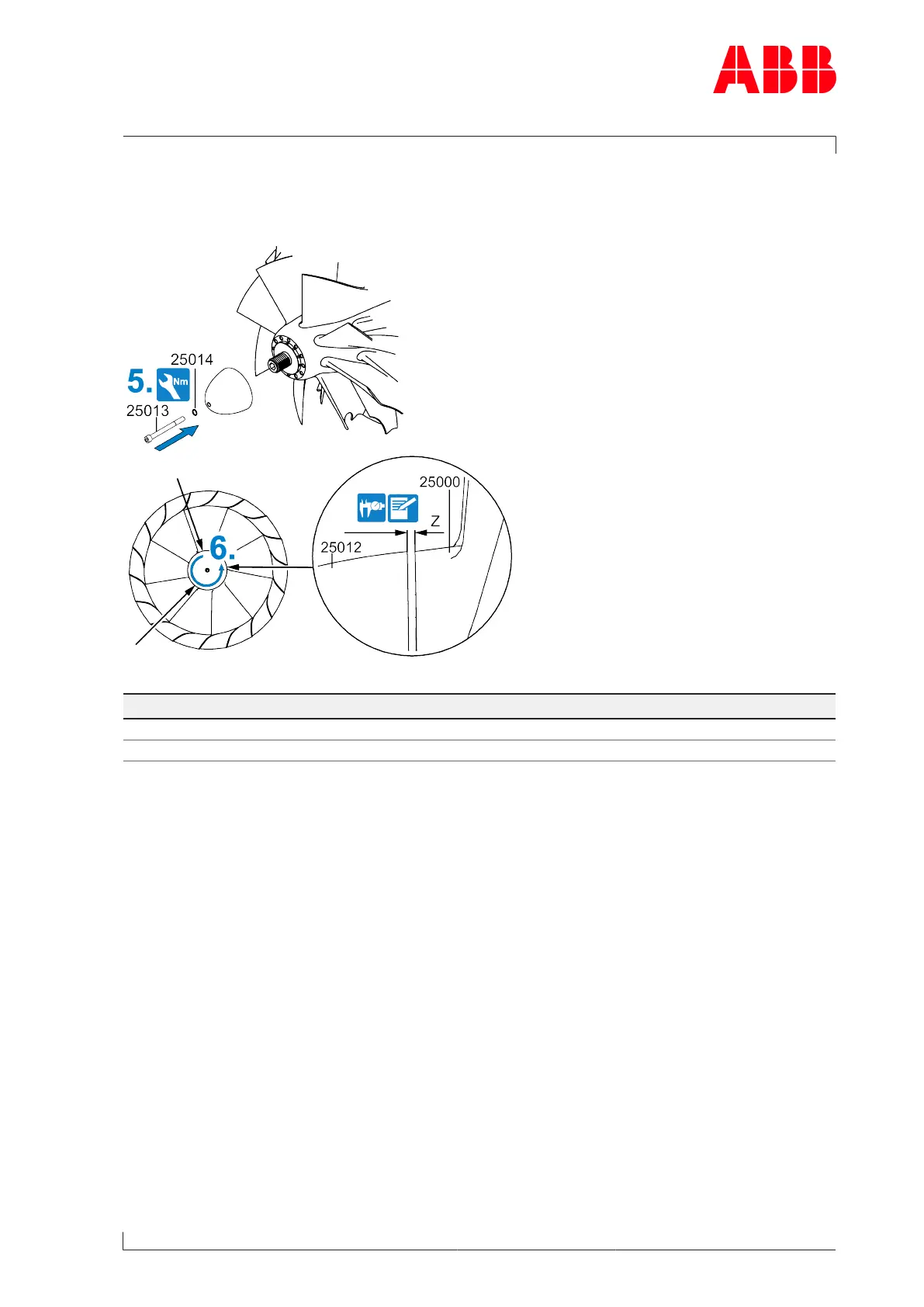

6. Measure and note down distance Z between spinner nose cone and compressor wheel at

no less than three points around the circumference.

Permissible distance Z: 0.1 – 0.7 mm

Permissible difference of the measurements: ± 0.1 mm

Page 103 / 146

Loading...

Loading...