26 EL3000 CONTINUOUS GAS ANALYZERS | CI/EL3000-EN REV. C

… 3 Preparation for Installation

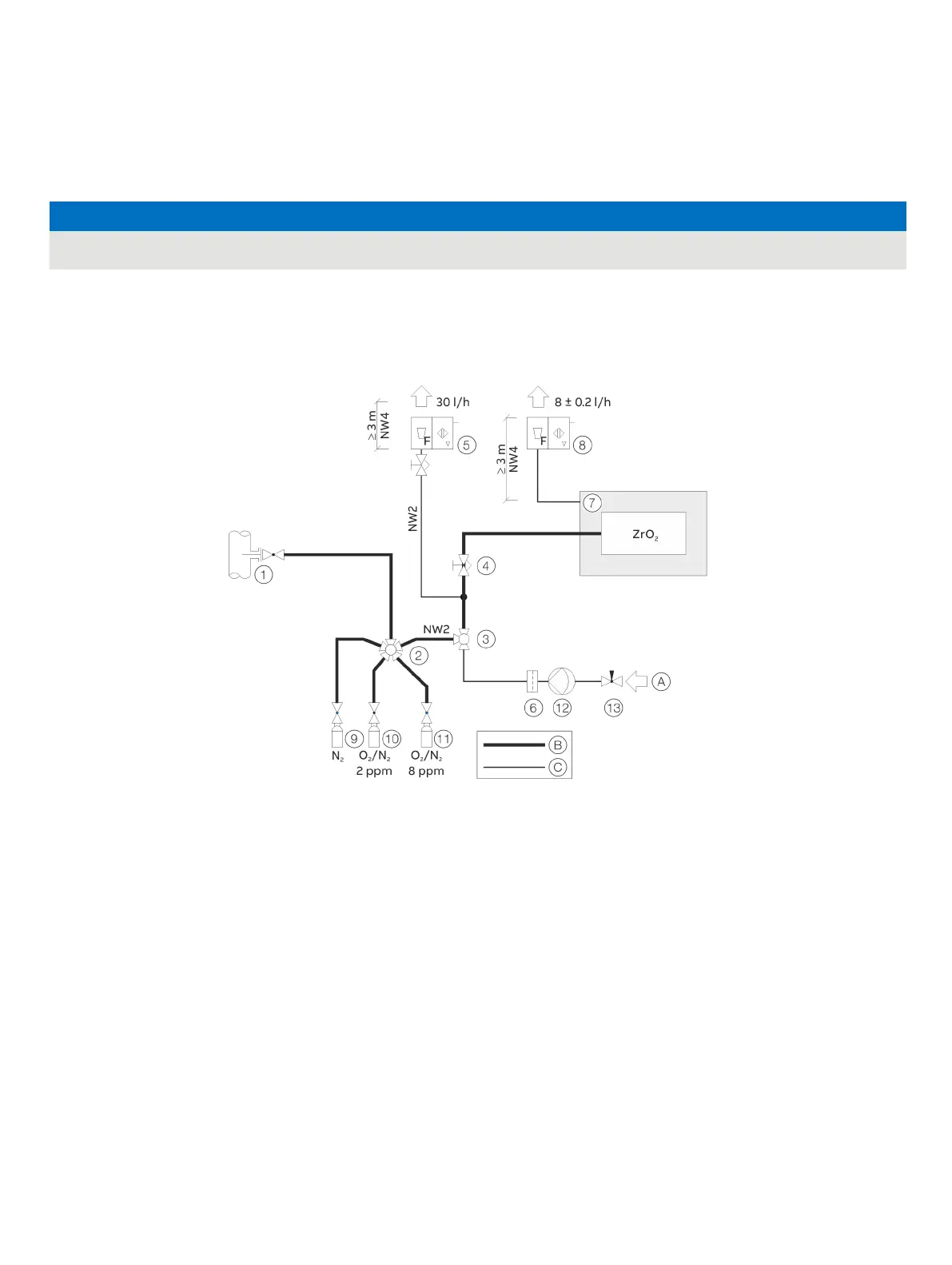

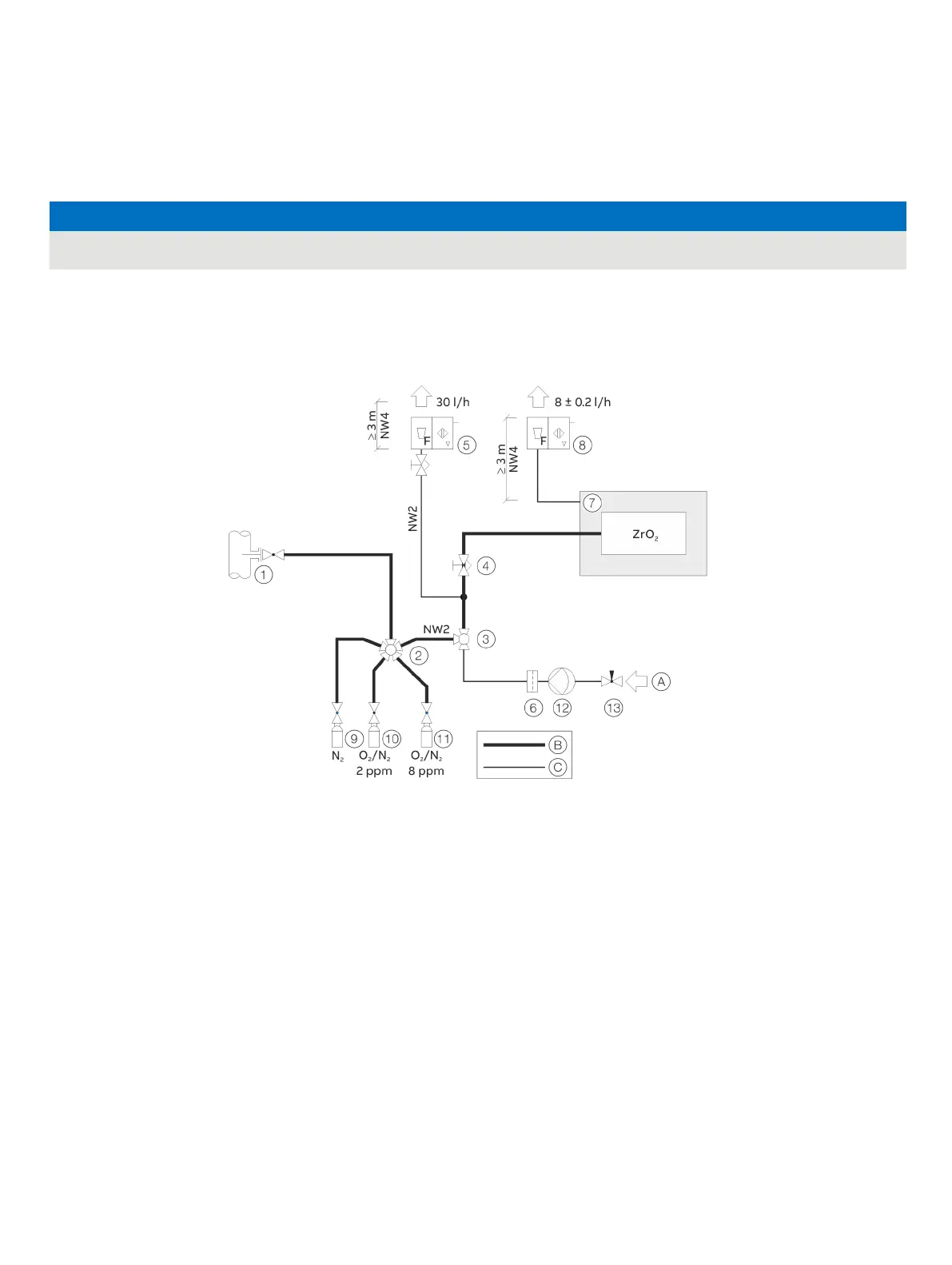

… ZO23

Installation and sample handling

Damage to the measuring cell

The ingress of liquids into the analyzer module can cause serious damage including destruction of the sample cell.

Note

The following information on installation and the sample handling must be considered for the measurement and the execution of

controlled calibrations (manual, automatic and externally controlled calibration).

Manually operated cocks and valves must be replaced by controlled valves suitable for the oxygen trace measurement, as required.

Reference air

Stainless steel pipe

FPM hose

Sampling point with primary shut-off valve

Multi-way ball valve

3/2-way ball valve

*

Fine-control and shut-off valve

Flowmeter with needle valve and fault-signalling contact

Air filter

*

Gas analyzer

Flowmeter without needle valve, with fault-signalling contact

Purge gas cylinder N

2

*

Test gas cylinder with for example 2 ppm O

2

in N

2

**

Test gas cylinder with 8 ppm O

2

in N

2

*

Pump*

Needle valve*

Option

A hard-mounted test gas cylinder is normally adequate.

The annual check of the reference point can also be carried out with a non-stationary air supply.

Figure 1: Sample handling example

Loading...

Loading...