84 EL3000 CONTINUOUS GAS ANALYZERS | CI/EL3000-EN REV. C

… 4 Installation

Fidas24 – Connect gas lines

Safety instructions

Explosion hazard

Explosion hazard due to leaking combustion gas in the gas

analyzer.

• The leak tightness of the combustion gas supply line

outside the gas analyzer as well as the combustion gas

path in the gas analyzer must be checked regularly.

• The relevant safety regulations for working with combustion

gases must be complied with!

• The screwed connections of the gas paths in the gas analyzer

may not be opened! The gas paths can become leaky as a

result.

– However, if the screwed connections of the gas paths in

the gas analyzer have been opened (only by trained

personnel), a leak tightness test must be performed

using a hydrogen detector (for example, based on

thermal conductivity) must always be carried out after

they have been sealed again. The leakage rate must not

exceed 10

-4

hPa⋅l/s.

• The lines and fittings must be clean and free of any residues

(for example, particles left from manufacturing)!

– Contaminants can enter the analyzer and damage it or

lead to false measurement results!

Notes

• The installation of gas connections is described in Mounting

the fittings on the gas analyzer on page 41.

• Follow the manufacturer's installation instructions for the

fittings! In particular, hold the male fittings (gas

connections) in place when connecting the gas lines.

• When laying and connecting the gas lines, adhere to the

installation instructions provided by the manufacturers of

the piping!

• If gas lines made of stainless steel are connected to the

analyzer modules, the lines must be connected to the

building-side potential equalization.

• Never connect more than three analyzer modules in a series!

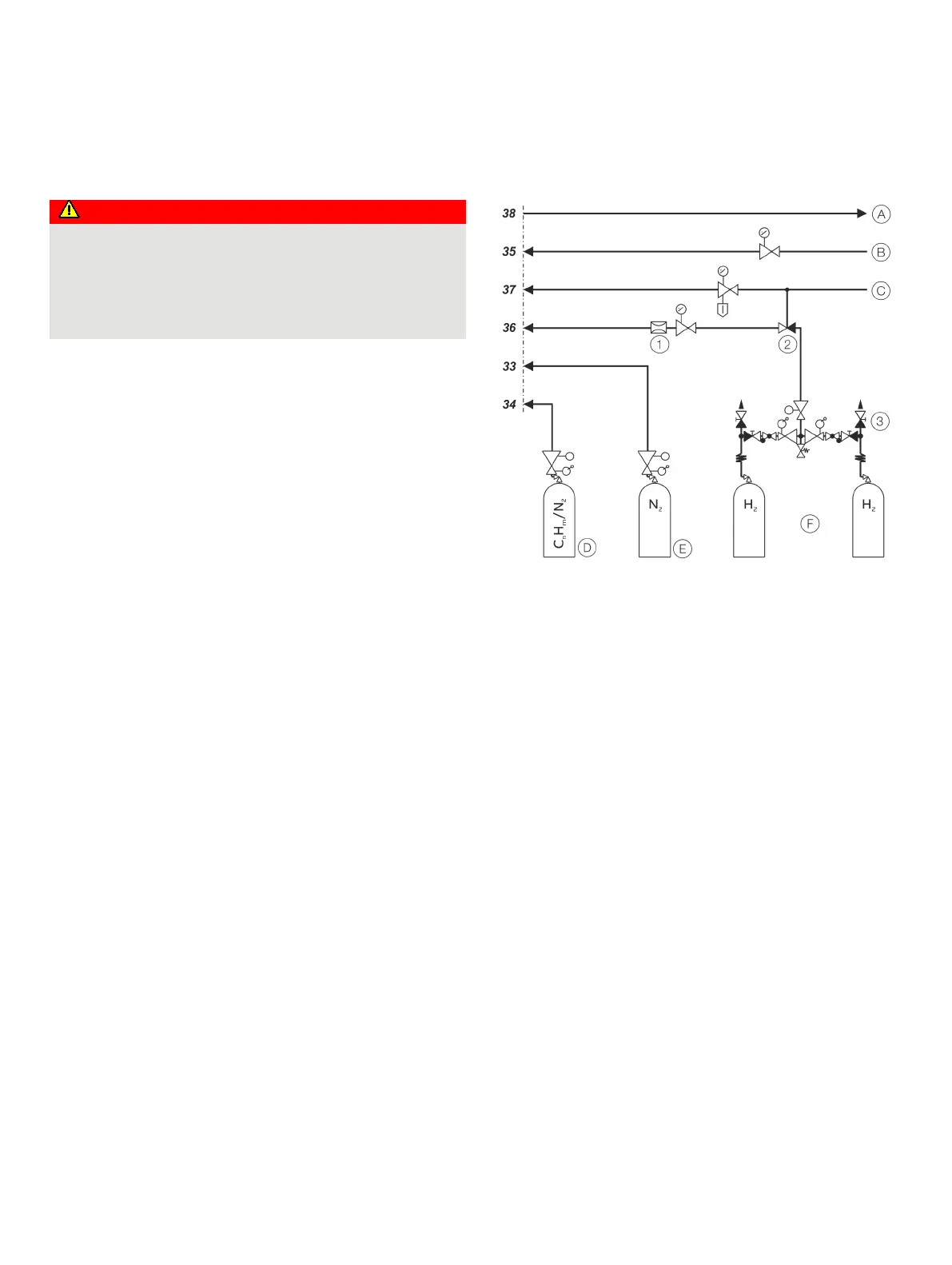

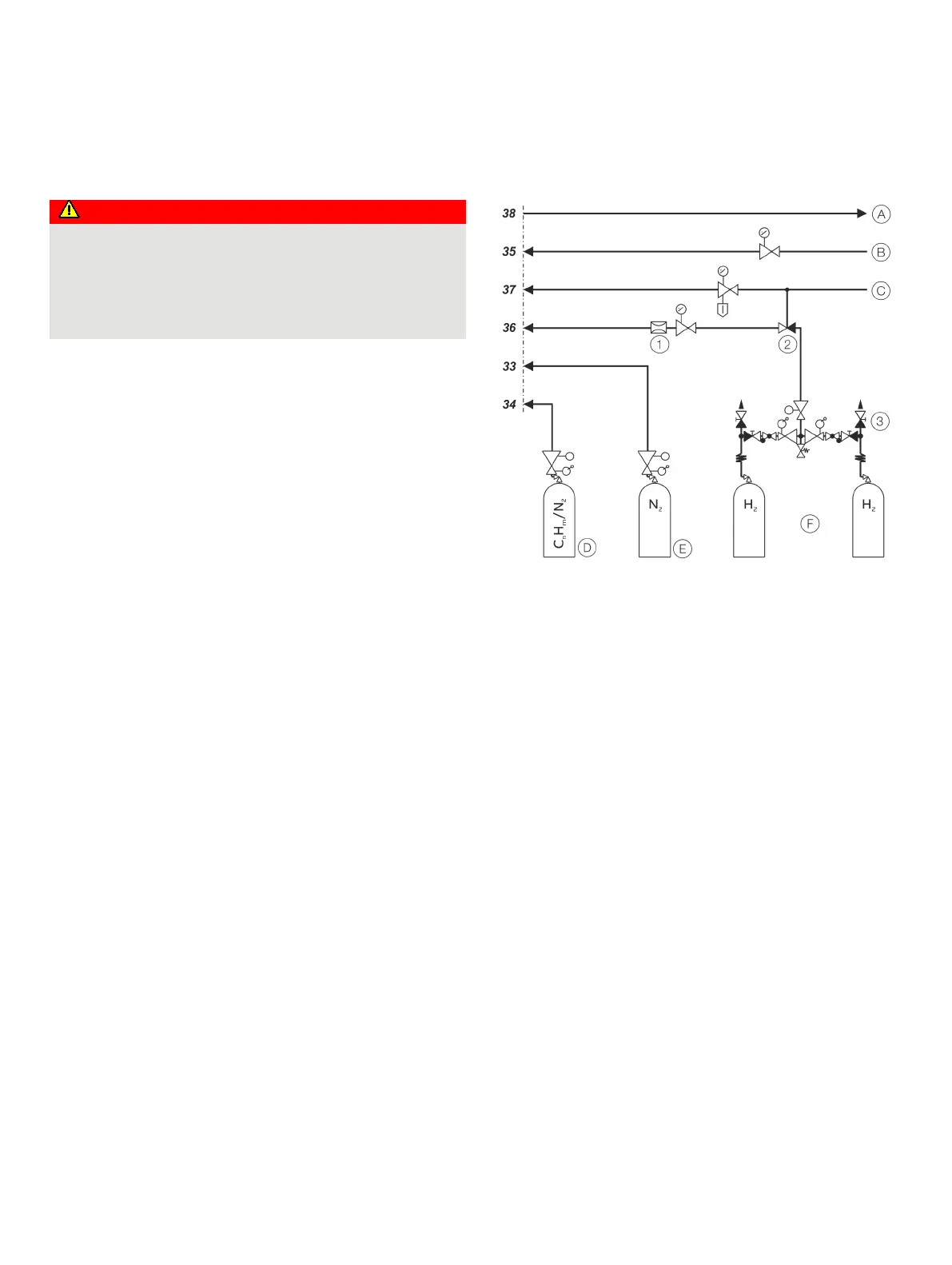

Connection of process gases and test gases

Flow restrictor

Pneumatic shutoff valve

Switching station with safety

valve

Exhaust air

Combustion air

pe = 1200 hPa, ±100 hPa

Instrument air

pe = 4000 hPa, ±500 hPa

Span gas

pe = 1000 hPa, ±100 hPa

Zero point gas

p

e

= 1000 hPa, ±100 hPa

Switching station with safety

valve

combustion gas pe = 1200 hPa,

±100 hPa

Figure 34: Connection of process gases and test gases

The numbering of the gas connections corresponds to the

numbering in Figure 32 and Figure 33 as well as the labeling on

the rear of the gas analyzer.

Instrument Air Connection

The instrument air is used as propulsion air for the air jet

injector, and as purging air for the housing purging, see Housing

purge on page 33.

Connect the instrument air line to the instrument air inlet 37 of

the gas analyzer via a pressure regulator (0 to 6 bar).

Combustion air connection

Connect. the combustion air line to the combustion air inlet 35

of the gas analyzer via a pressure regulator (0 to 1.6 bar).

Combustion gas connection

See section Combustion gas connection on page 84.

Loading...

Loading...