Installing the Gas Analyzer 41

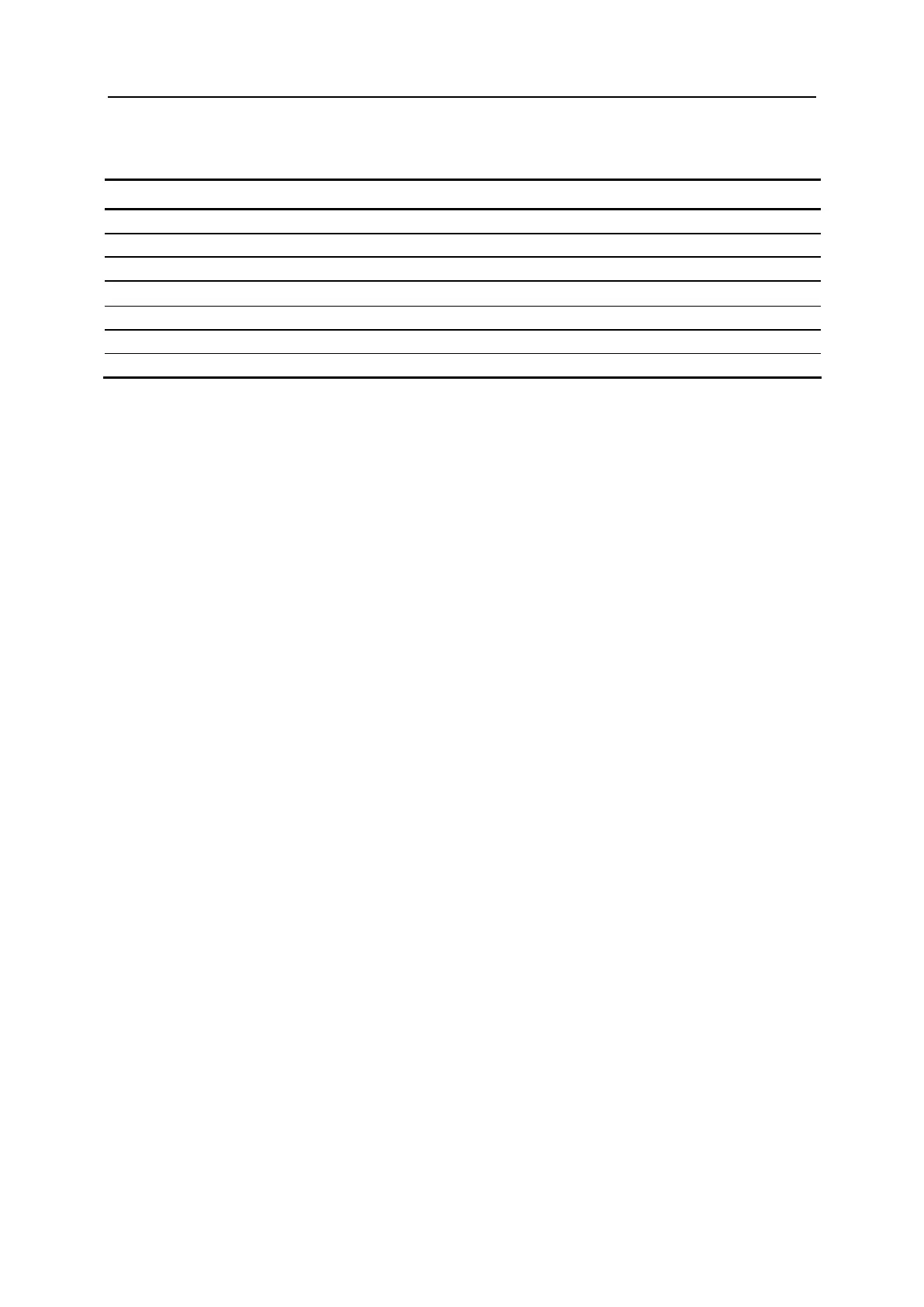

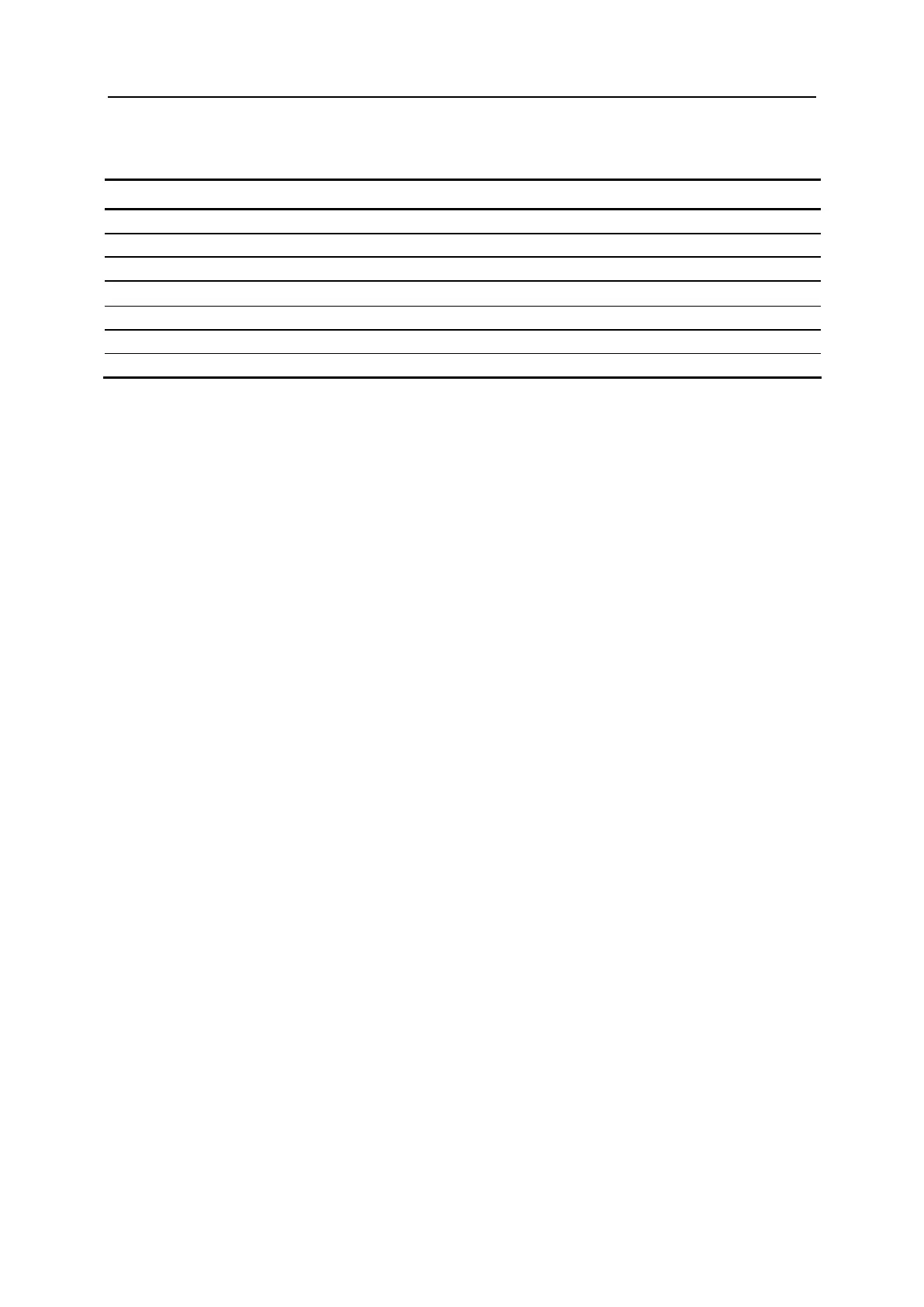

Assignment of the Connecting Cables to the Cable Connectors

Connecting Cable Screwed Cable Gland Permissible External Diameter of Cable

Gas analyzer power supply Plastic M16 4…8 mm

Power supply to EL3060-Uras26 Metal M20 7…12 mm

Data transfer for EL3060-Uras26 Metal M20 7…12 mm

Ethernet Metal M16 3…7 mm

Profibus/Modbus Metal M16 3…7 mm

Analog outputs Plastic M20 6.5…12 mm

Digital inputs/outputs Plastic M20 6.5…12 mm

Loading...

Loading...