Electrical connection

14 TTR200 OI/TTR200-EN

Pos: 14.5 /Überschri ften/1.1/1-spa ltig/A - C/Anschlussbe legung @ 16\mod_1199260233 671_3101.doc @ 146854

5.2 Pin configuration

Pos: 14.6 /Überschri ften/1.1.1/1-spal tig/Versorgungs- / Sensoranschluss @ 16\ mod_1199260387640_3101. doc @ 146877

5.2.1 Supply voltage / sensor connection

Pos: 14.7 /Elektri scher Anschluss/Temper atur/TTR200/Anschl ussplan (BA) @ 18\mod_12 03682458036_3101.doc @ 164662

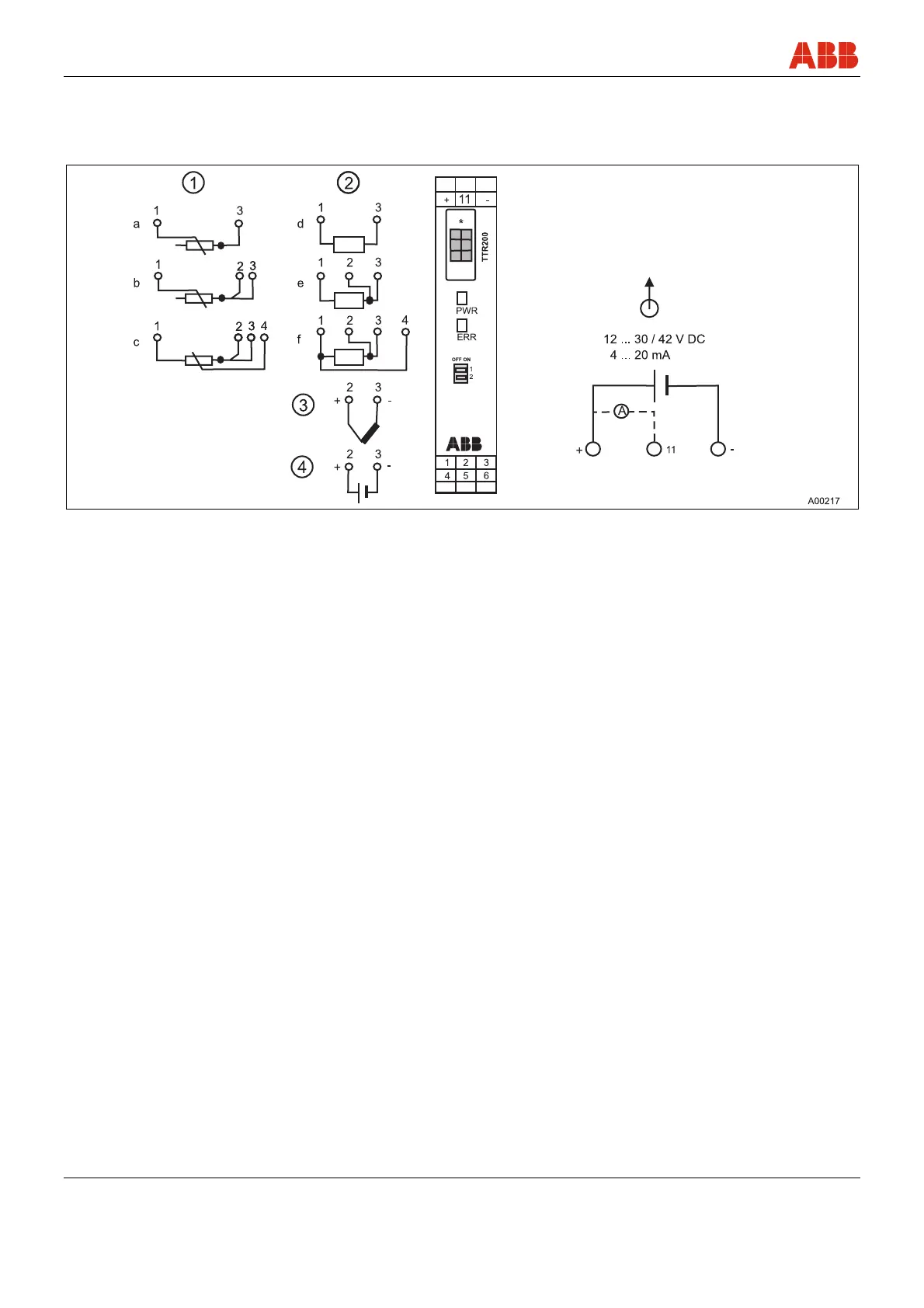

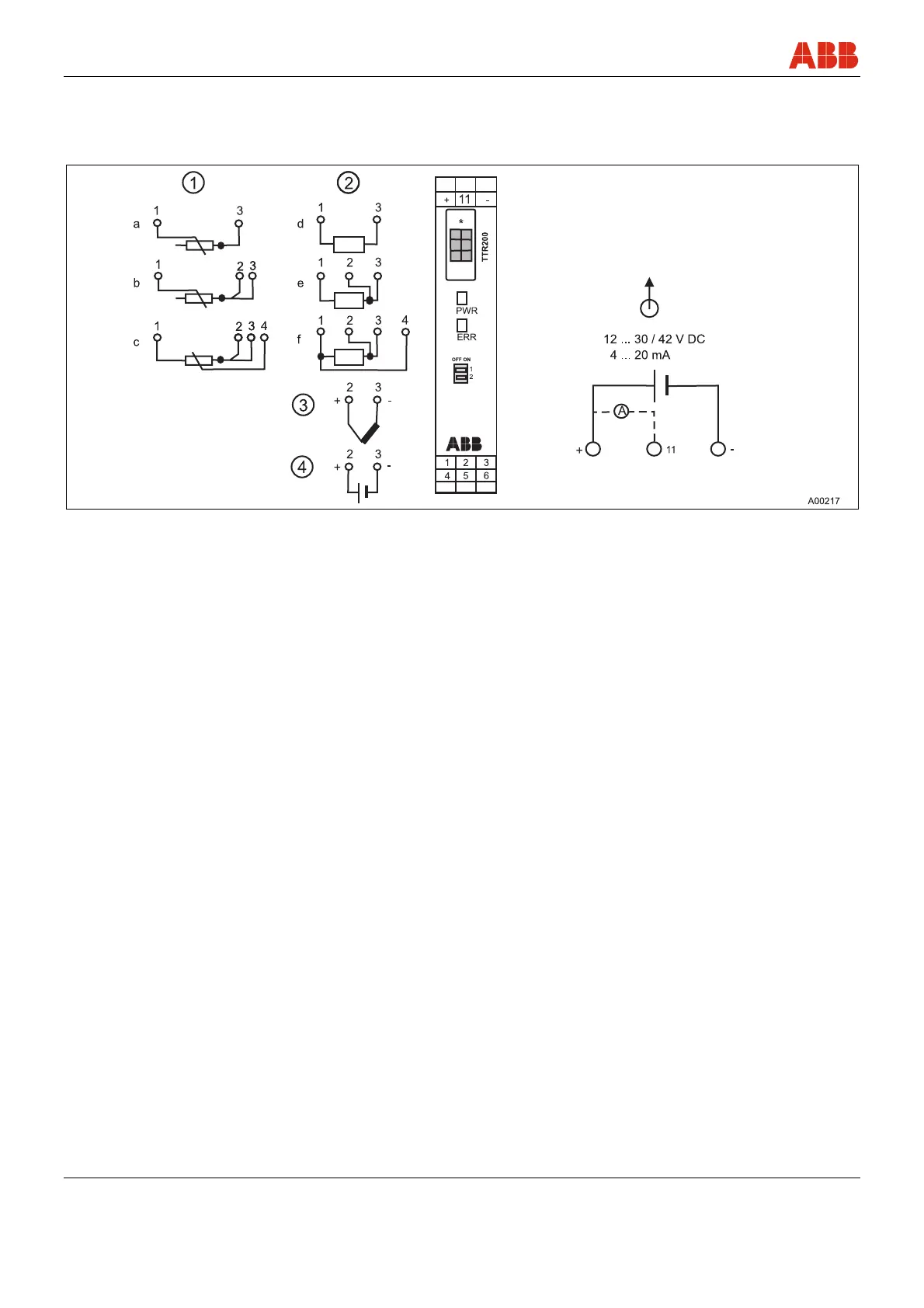

Fig. 3: *(planned local configuration interface/inoperable)

1 Potentiometer: 0 … 500 Ω or 0 … 5000 Ω

a Potentiometer, 2-wire circuit

b Potentiometer, 3-wire circuit

c Potentiometer, 4-wire circuit

2 RTD resistance sensors (e.g., Pt100)

d RTD, 2-wire circuit

e RTD, 3-wire circuit

f RTD, 4-wire circuit

3 Thermocouple

Depending on the sensor model, a variety of line materials can be used

for sensor connections. The integrated reference point makes it possible

to directly connect thermal compensating lines.

4 Voltage measurement

Pos: 14.8 /Elektri scher Anschluss/Temper atur/TTR200/Anmerkun g zu Anschlussplan ( BA) @ 18\mod_1205827740529 _3101.doc @ 170993

Note

Terminal 11: Measurement of 4 … 20 mA output current without opening / interrupting the current loop (see chapter

5.3 Block diagram )

• PWR / green LED: Supply voltage display

• ERR / red LED: sensor, sensor lead & unit fault signaling

• DIP switch 1: on -> Hardware write protection is enabled

• DIP switch 2: no function

Pos: 14.9 /====== = Seitenumbruch ======= = @ 0\mod_1126532365768_3101.doc @ 3830

Loading...

Loading...