2 I

I - 1 Fundamentals of Positioning

I - 1 Fundamentals of Positioning

Datums

The workpiece drawing identifies a certain point on the workpiece

(example: “a corner”) as the absolute datum, and perhaps one, or

more other points as relative datums.

The datum setting procedure establishes these points as the origin of

the absolute, or relative coordinate systems. The workpiece, which is

aligned with the machine axes, is moved to a certain position relative

to the tool. The display is set either to zero, or to another appropriate

value (e.g., to compensate for tool radius).

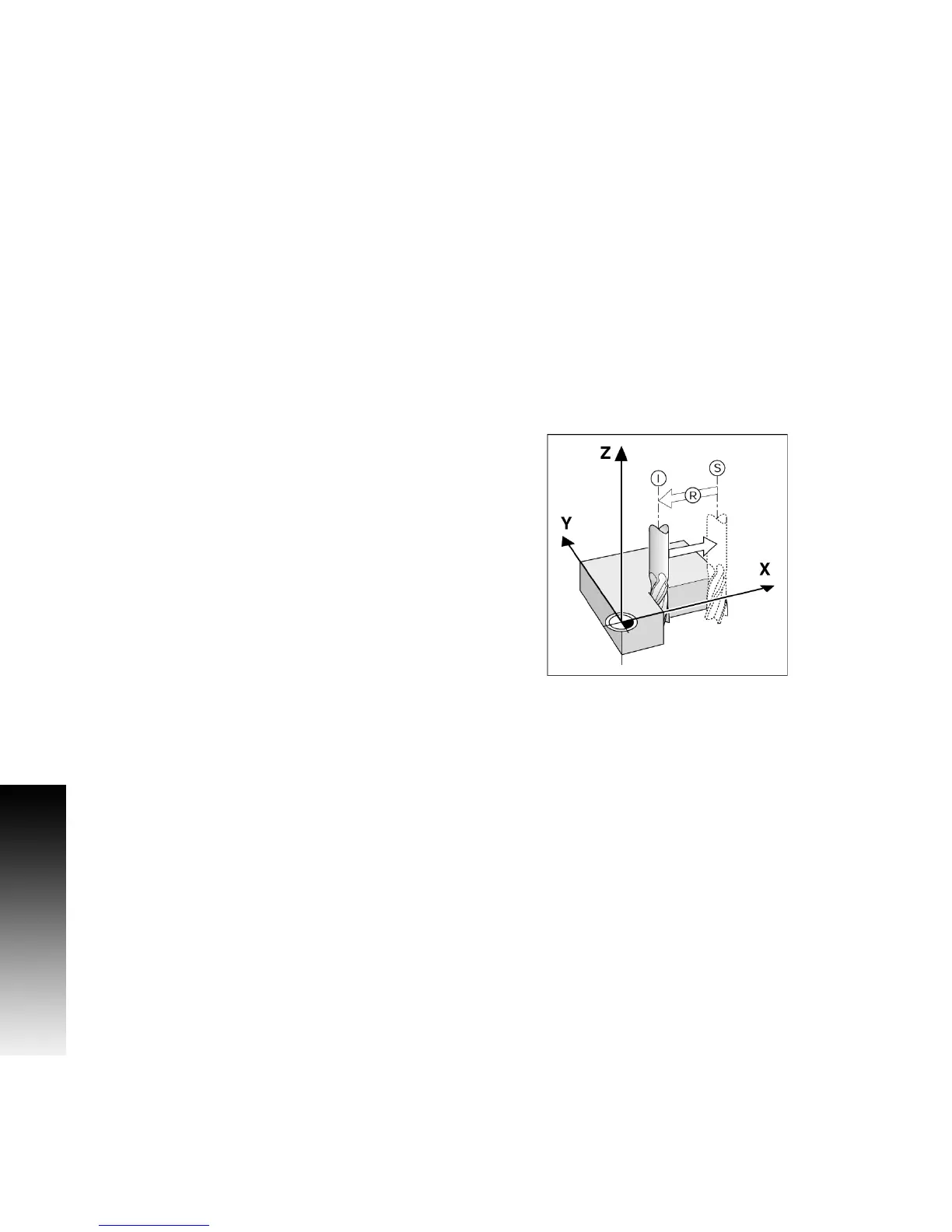

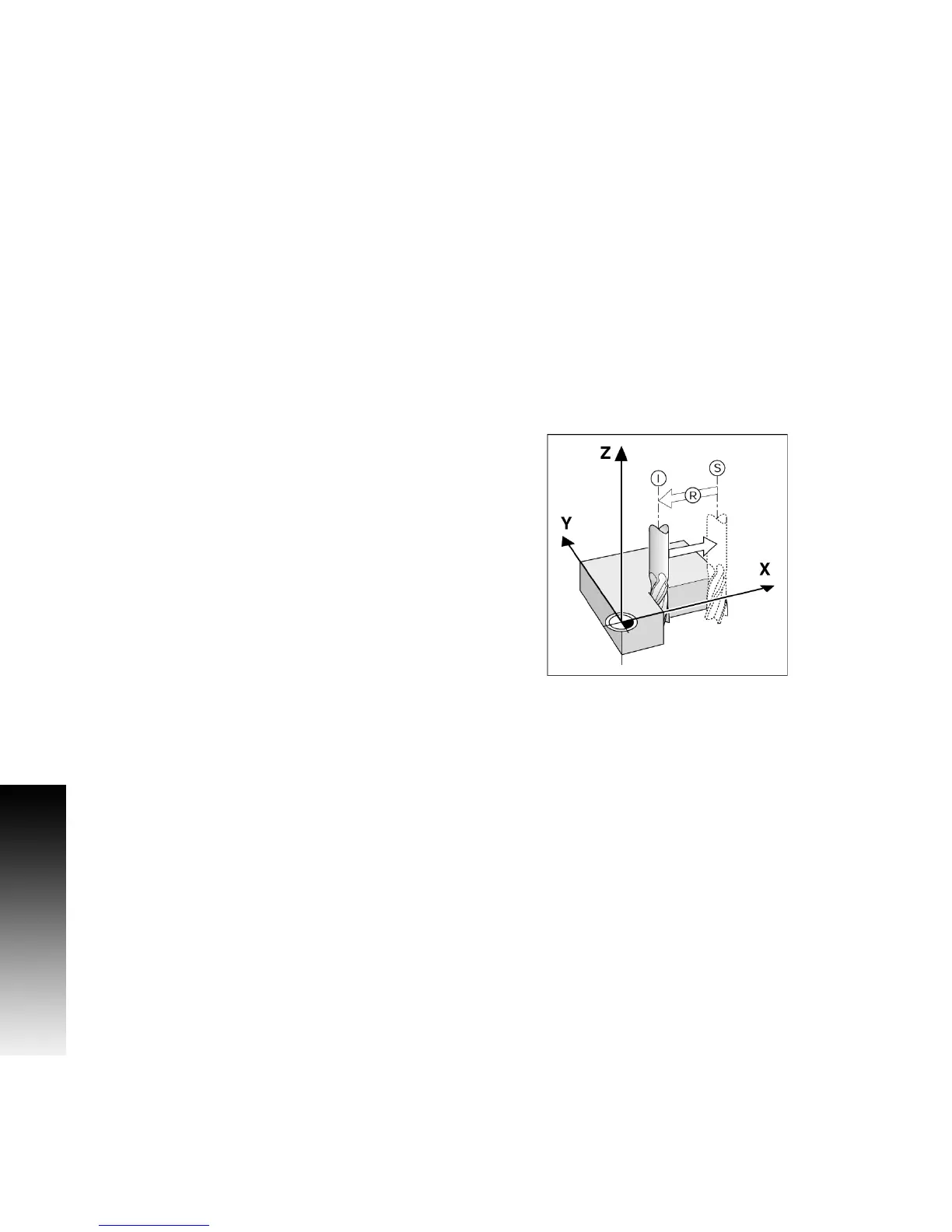

Actual Position, Nominal Position, and

Distance-To-Go

The position of the tool at any given moment is called the ACTUAL

POSITION I, while the position that the tool is to move to is called the

NOMINAL POSITION S. The distance from the nominal position to

the actual position is called the DISTANCE-TO-GO R.

Loading...

Loading...