Behavior models used in CIP Motion

68 Rockwell Automation Publication MOTION-RM003I-EN-P - February 2018

controller is responsible for rolling up all the conditions of the system into the

Axis State that is presented to you.

Since faults are latched conditions, a Fault Reset is required to clear the faults and,

assuming the original fault condition has been removed, the axis transitions to the

Axis State of motion device. There are many different sources of Faults: CIP

Initialization Faults, CIP Axis Faults, Motion Faults, Module Faults, Group

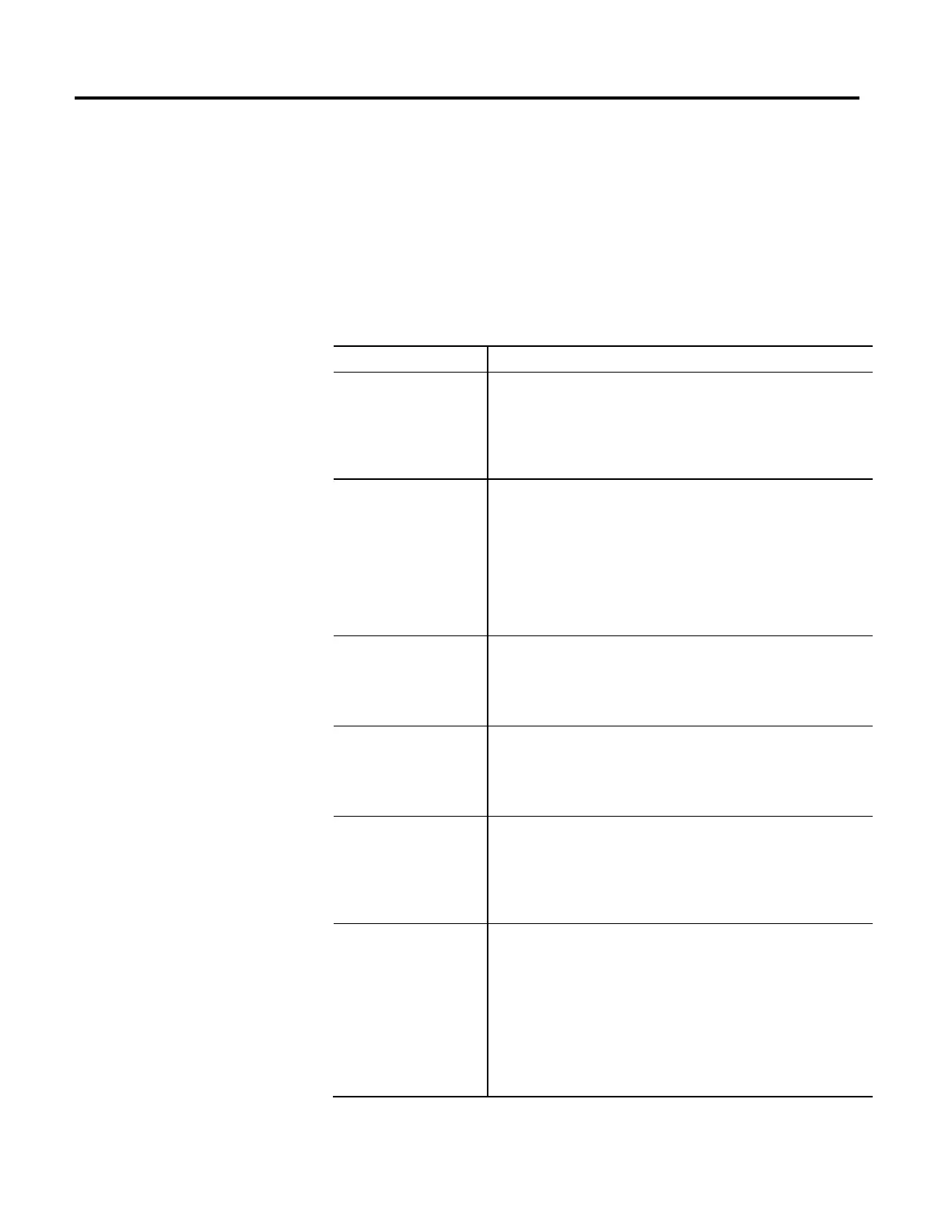

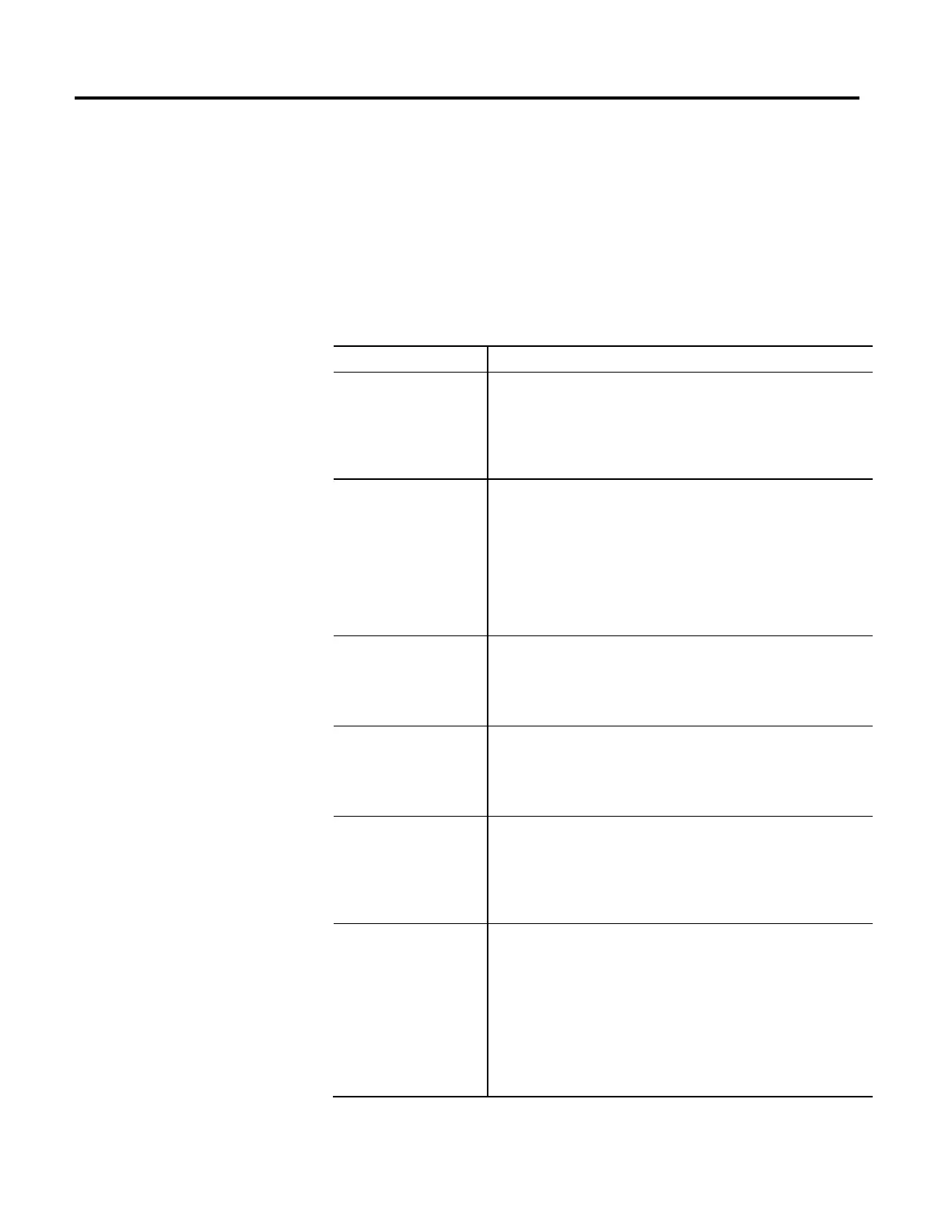

Faults, Safety Faults, and Configuration Faults. The following table describes the

sources of these faults:

Fault Source

CIP Initialization Faults

These faults can only occur during the Initializing state. You cannot generate an

Initialization fault in any other state of the drive, for example, faults occurring during

operation of the drive after transitioning out of the Initializing state. Initialization

Faults can apply to a specific axis or to the entire drive, in which case all device axis

instances would indicate the Initialization Fault. The device power structure, if

applicable, is disabled when there is a CIP Initialization Fault present.

CIP Axis Faults

As the name implies, CIP Axis Faults apply to a specific device axis instances. CIP Axis

Faults are the direct result of Axis Exceptions that are configured to generate a Fault

response. These exception conditions may apply to individual axis instances or to all

axis instances. In any case, applications may require the device be configured to handle

these exceptions differently for different axes. Run time conditions related to Motor,

Inverter, Converter, Bus Regulator, and Feedback components, in general, shall be

handled as Axis Exceptions. The power structure if applicable, may or may not be

disabled when there is a CIP Axis Fault present depending on the specific stopping

action applied by the device in response to the fault condition.

Axis Safety Faults

Axis Safety Faults also apply to specific axis instances. Safety Faults are reported by the

embedded Safety Core of the device that is responsible for monitoring the condition of

various critical safety functions associated with the axis. This embedded Safety Core has

a CIP Safety connection to an external Safety Controller. When an Axis Safety Fault

occurs, the safety system is responsible for forcing the axis into a Safe State.

Guard Faults

These faults also apply to a specific axis instance. Guard Faults are generated by a fault

condition detected in the drive's "Hardwired" safety monitor functionality (SMSC). This

component of the drive is designed to monitor various critical safety functions of the

drive and put the axis in a safe state if any monitored condition fails to operate

nominally.

Motion Faults

These faults are generally associated with fault conditions generated by the motion

planner function. These faults can include conditions related to the input (for example,

actual position) and output (command position) signals to the motion planner. The

device power structure, if applicable, may or may not be disabled when there is a

Motion Fault present depending on the specific stopping action applied by the system

in response to the fault condition.

Module Faults

These faults apply to the entire motion device and affect all axes associated with that

device. These faults can occur at any time during device operation. Module Faults

include all Node Faults reported by the device, which are primarily communication

faults, but can include general hardware faults where these fault conditions are

checked during run-time. A CPU watchdog fault would be an example of a hardware

CIP Node Fault. Module Faults also include communication fault conditions detected on

the controller side of the motion connection. An example of a controller side Module

Fault would be the Control Sync Fault. The device power structure, if applicable, is

disabled when there is a Module Fault present with the controller initiating the

equivalent of a shutdown fault action.

Loading...

Loading...