Section 2

2 - 5

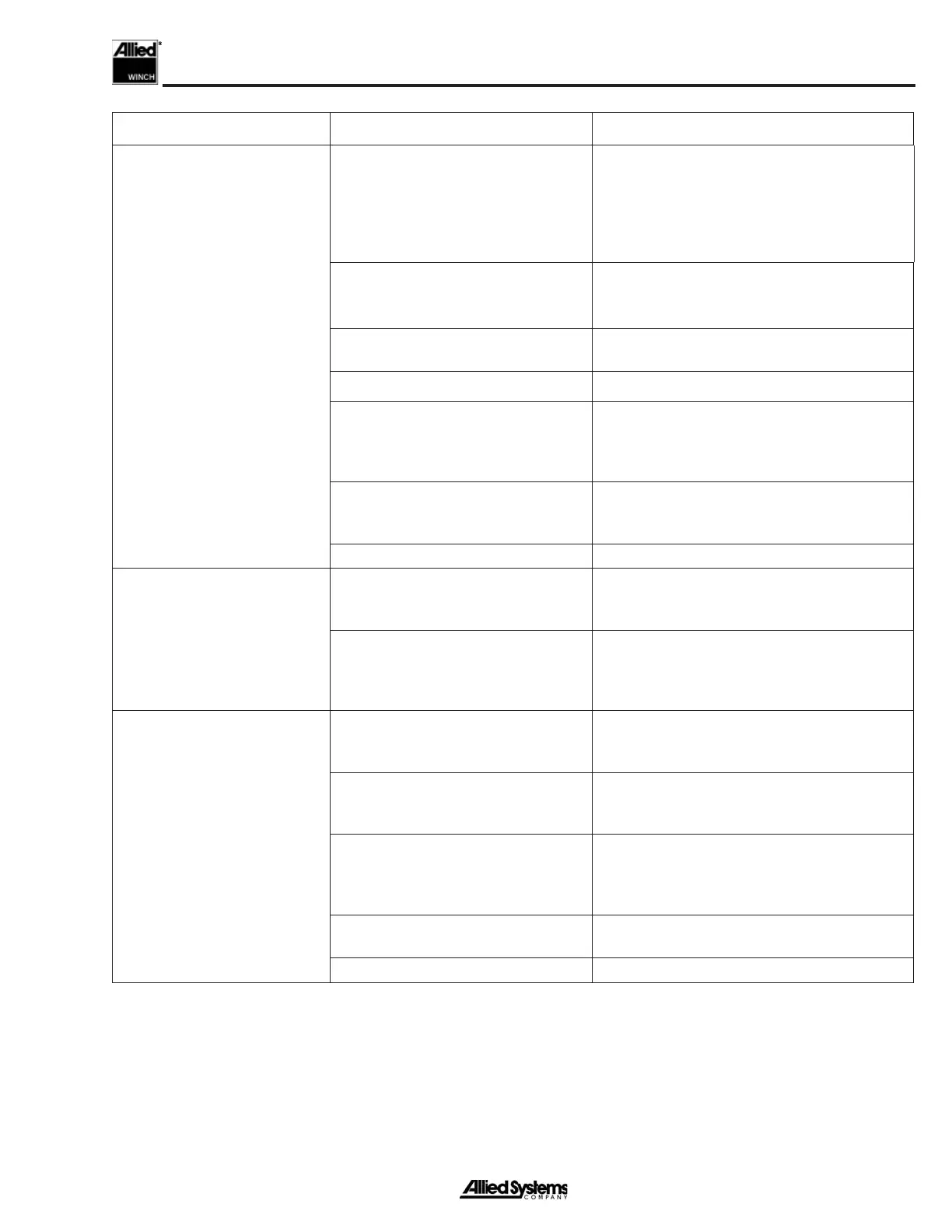

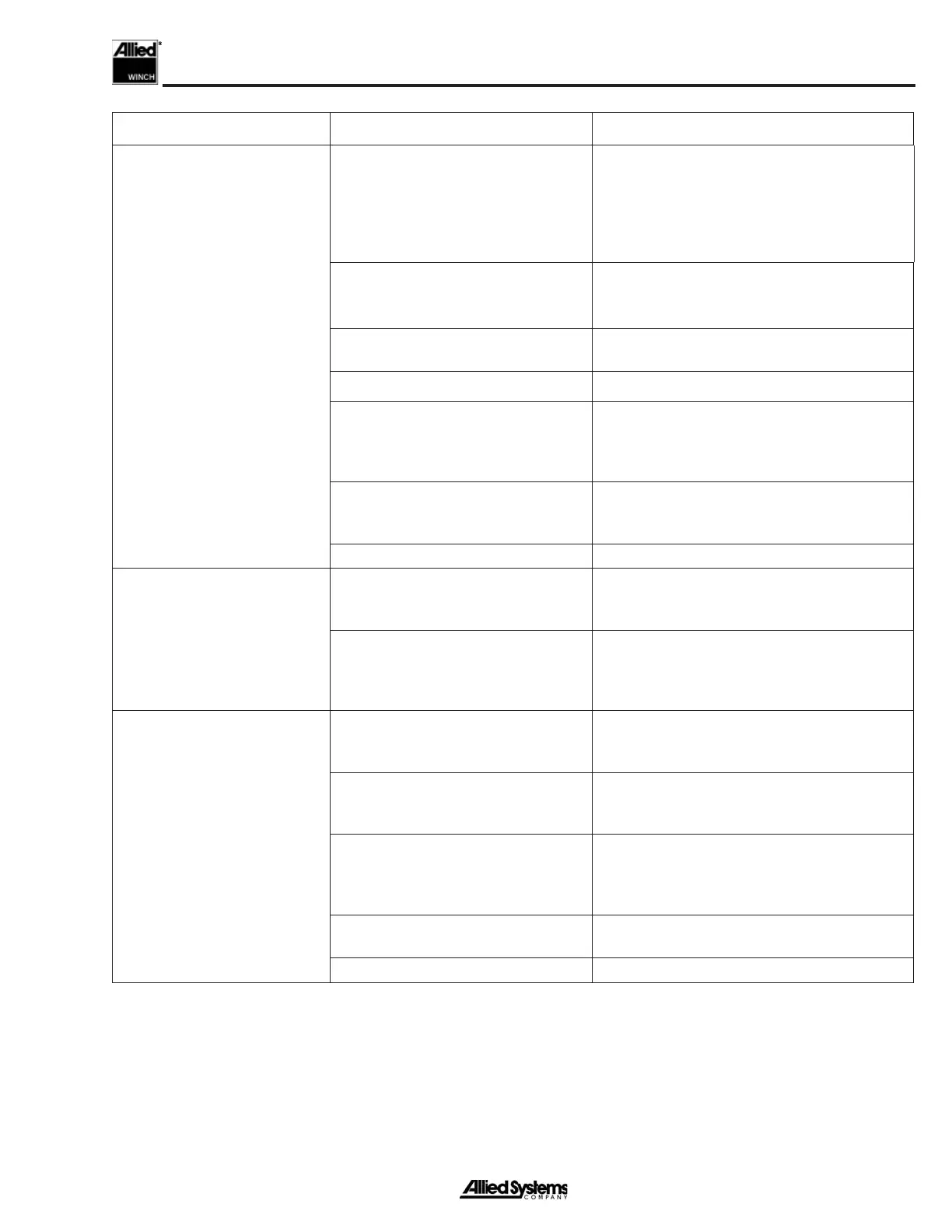

PROBLEM POSSIBLE CAUSE CORRECTION

Winch will not generate suffi -

cient line pull or does not LINE

-IN or LINE-OUT

(Continued from previous

page)

Leak in motor speed spool relief car-

tridge (HI-SPEED only).

Check that the pressures at motor test Ports

A & B are suffi cient for operating the winch in

LINE-IN/OUT with the brake line plugged. If the

pressure is low and registered simultaneously

at Ports A and B, leakage is occurring past the

relief valve. Remove and repair the valve.

Clogged fi lter. Tractor fi lter indicator light will illuminate if

fi lter is clogged. Replace fi lter. Refer to tractor

specifi cations.

Wrong oil. Use correct oil grade; refer to tractor oil speci-

fi cations.

Low oil level in reservoir. Add oil; refer to tractor oil specifi cations.

Tractor pump not generating ad-

equate pressure.

Hold blade over relief and measure supply

pressure at right side of dozer. If pressure is

below 3625 psi see tractor service manual for

proper adjustment.

Damaged FREESPOOL components

may be causing winch to be stuck in

FREESPOOL.

Inspect FREESPOOL shaft for wear or dam-

age, repair or replace as necessary.

Motor damaged. Repair or replace motor (refer to Section 4).

BRAKE-OFF function will

not operate or is difficult to

engage.

BRAKE-OFF solenoid is not ener-

gized.

Check resistance to ensure it’s 35 ohms at the

coil. Repair power supply or replace coil and/

or solenoid.

Insuffi cient control pressure from trac-

tor pilot supply.

1. Measure control pressure to BRAKE-OFF

bypass valve (170 psi to shift).

2. Check for leaks at hydraulic connections.

3. See Pilot Supply Relief Adjustment.

FREESPOOL will not function

or is diffi cult to engage.

FREESPOOL shifter fork or collar

stuck.

Remove top covers and inspect shifter fork &

collar with joystick in FREESPOOL position.

Repair parts if damaged.

Leakage at hydraulic connection or

FREESPOOL shaft.

Remove top covers and inspect shifter fork

with joystick in FREESPOOL position. Replace

seals if leaking.

Insuffi cient control pressure from trac-

tor pilot supply.

1. Measure control pressure at brake (BR)

port and FREESPOOL (FS) hose (refer

to Section 3).

2. Check for leaks at hydraulic connections.

FREESPOOL solenoid is not ener-

gized.

Repair power supply or replace coil and/or

solenoid.

Load on wire rope. Move lever to LINE-OUT to release load.

Figure 2-2 Troubleshooting Chart_2

Loading...

Loading...