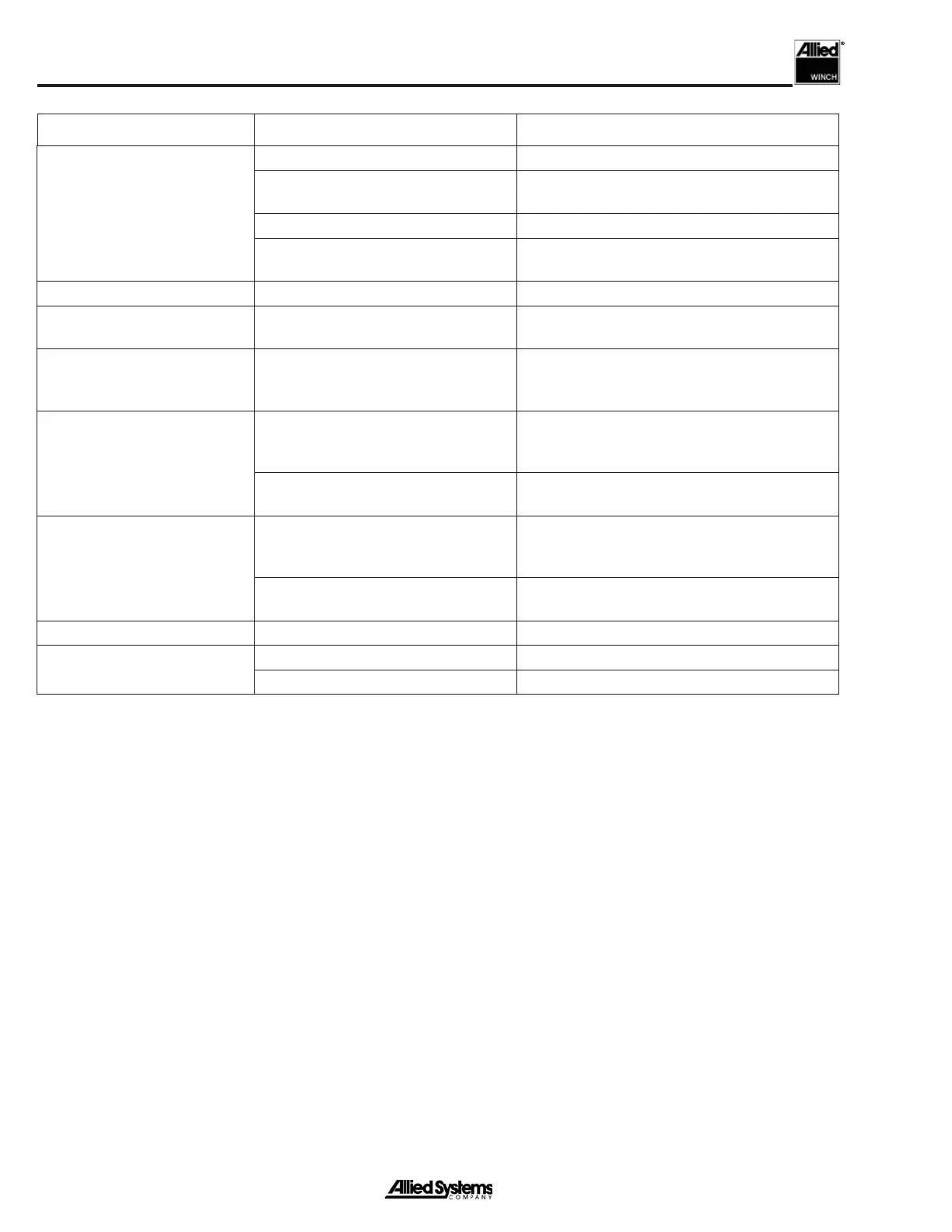

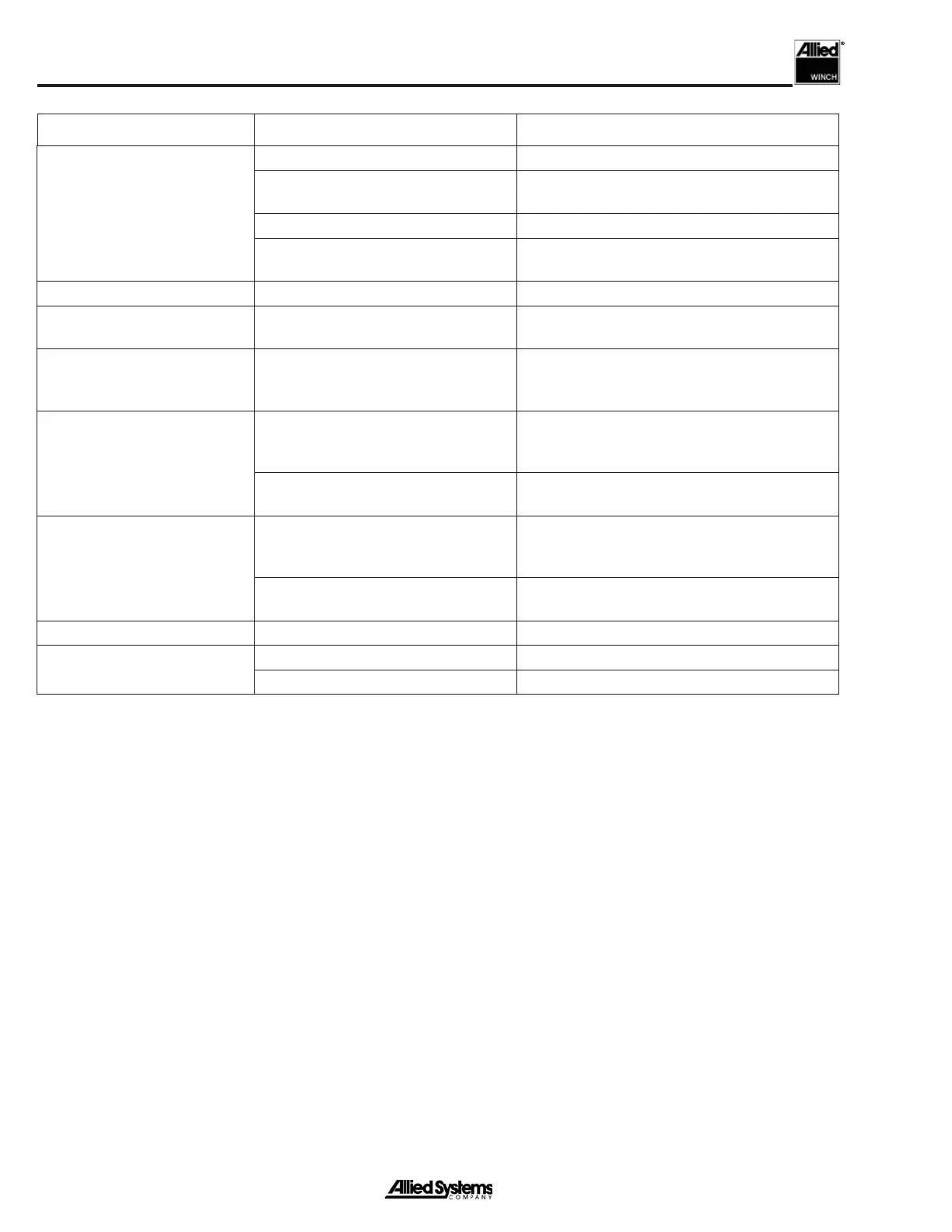

Troubleshooting

2 - 6

PROBLEM POSSIBLE CAUSE CORRECTION

HI-SPEED function will not

operate.

2-speed spool in motor stuck. Clean and/or repair 2-speed spool.

2-speed pressure switch malfunction-

ing (normally closed.)

Repair or replace 2-speed pressure switch.

2-speed relay malfunctioning. Repair or replace relay.

2-speed solenoid is not energized. Repair power supply or replace coil and/or

solenoid.

Winch case oil level too high. Too much oil added. Drain oil until level at oil level plug.

Winch case oil level too high

and tractor reservoir too low.

Oil leak from FREESPOOL hose or

piston.

Visually inspect and repair as needed.

Lever does not automatically

return to BRAKE-ON posi-

tion.

1. Plunger seal sticking in lever.

2. Spring in pilot controller unit

broken.

Remove and inspect pilot controller unit on

joystick control assembly. Replace worn parts

or entire assembly as necessary.

Winch does not respond to

lever movement.

1. Leak in the pilot controller unit on

lever control assembly.

2. Control valve seized or blocked.

Check for leaks in lever control assembly and

replace if necessary.

Leak in hydraulic system, or loose

hydraulic connections.

Visually inspect winch for leaks, and ensure

hydraulic connections are secure.

Line speed is abnormally slow

for LINE-IN, LINE-OUT or

both.

1. Poor pressure signal.

2. Leak in the pilot controller unit in

the joystick control assembly.

Visually inspect to check for wear on joystick

control assembly. Check for leaks in pilot con-

troller unit and replace if necessary.

Leak in hydraulic system, or loose

hydraulic connections.

Visually inspect winch for leaks, and ensure

hydraulic connections are secure.

Lever handle turns. Handle parts loose. Tighten all lever handle parts.

LEDs in switch panel do not

illuminate.

Polarity backward. Reverse plug connection.

Faulty LED. Replace LED.

Figure 2-2 Troubleshooting Chart_3

Loading...

Loading...