Modbus Communication Interface | A-13

ANALYZER CONFIGURATION OPERATIONS

In this section, coniguring the analyser with the MODBUS is discussed. The 3050 analyzer

shipped ready to communicate via MODBUS using the serial communications port. While

the 3050 analyzer can be completely conigured using the MODBUS connection, AMETEK

recommends the use of the 3050 Conigurator software for coniguring the analyser. The

3050 conigurator software is also compatible with MODBUS RTU. Switching protocols

can be accomplished with the 3050 Conigurator software or with the AMETEK “ProtocolS-

witch” utility, which is discussed in the next section.

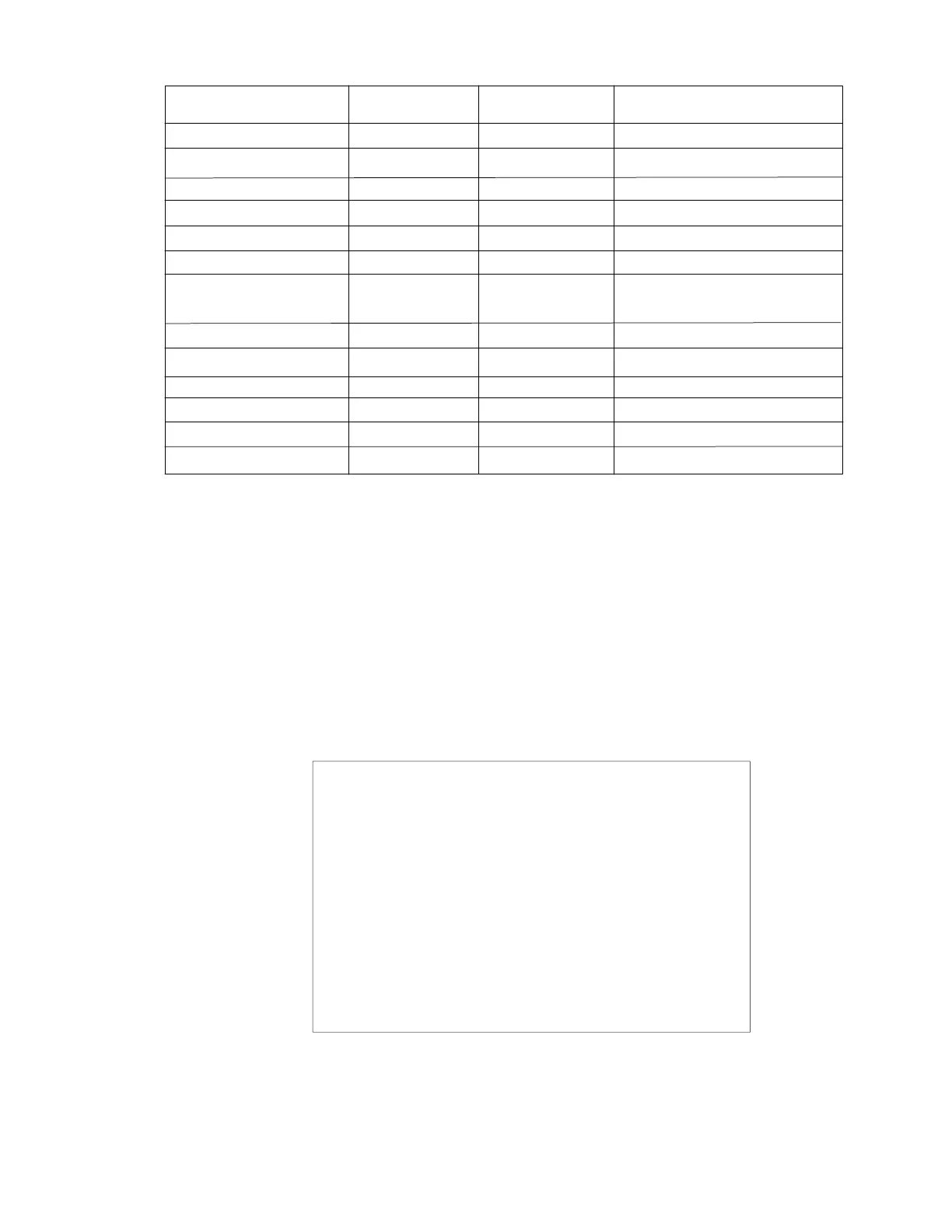

Figure A-5.

Alarm Register Value.

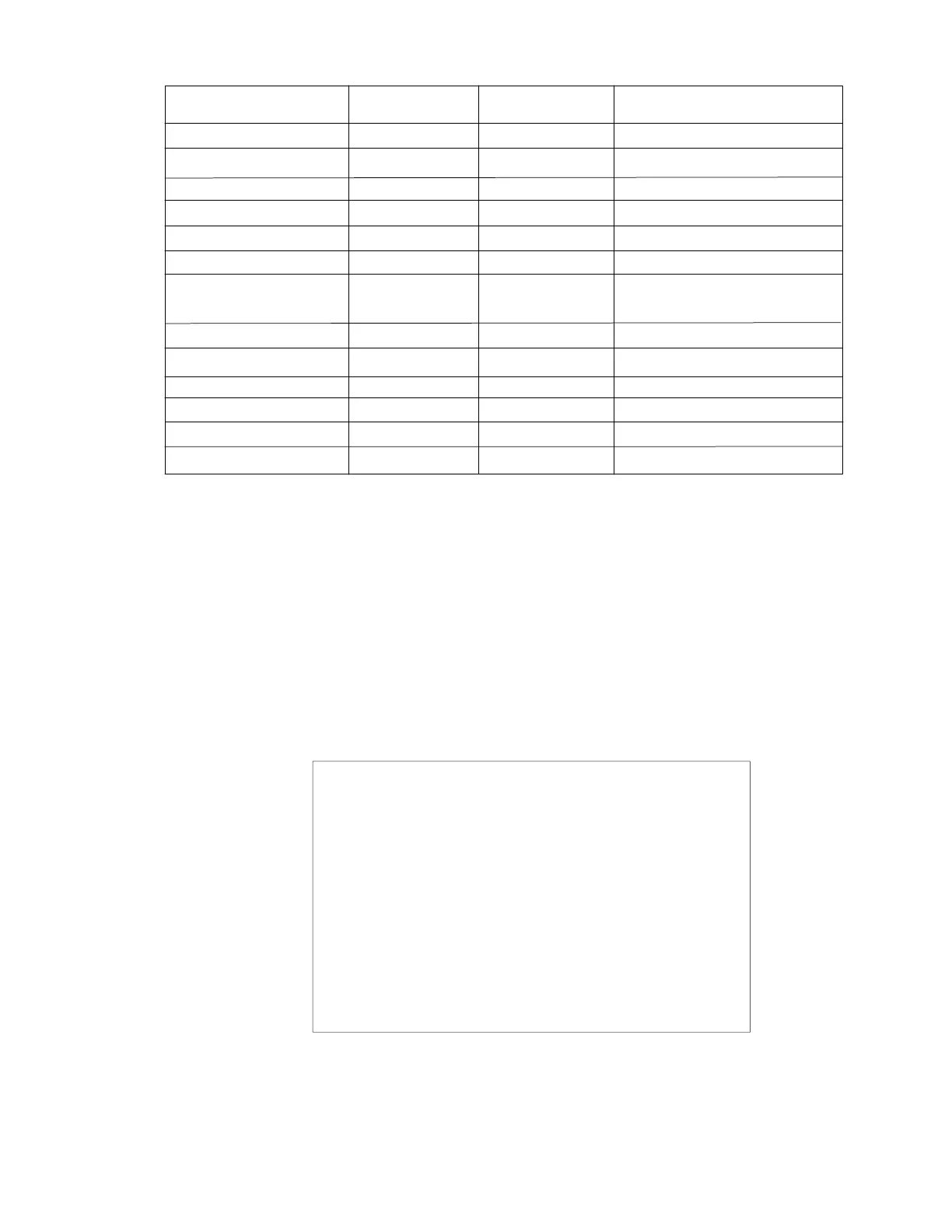

Figure A-6.

Holding Register Values.

ALARM NAME System State Bit Number of blinks Comment

Memory Failure Bit 4 1 System Alarm

Sensor Failure Bit 5 2 Frequency&Sensor Access

Calibration Failure Bit 6 3 Span Out of Limit

Oven Temperature Out Bit 7 4 Temperature Out of Limit

Flow Out of Range Bit 8 5 System Alarm

Battery Low Bit 9 6 BatteryState

Reference Gas Alarm Bit 10 7 Set if Delta Freq < -0.3Hz

Warnings

Enclosure Temperature Bit 11 8 Temp > 70 degrees C

Moisture Generator Date Bit 12 N/A Good for 2 years

Dryer Alarm Bit 13 10 Exceeding PPM Hours

Concentration Alarm Bit0 – Bit1 11 Concentration out of range

Invalid Reading Bit2 11 Verification or System Alarm

Process pressure Bit3 11 Process pressure out of limits

Value COMMAND DESCRIPTION

71 Start Verification Cycle

76 Load Sensor Memory

81 Quit Verification Cycle

82 Reset Analyzer

84 Start/Stop Test Mode

90 Start Zero Cycle

Loading...

Loading...