11-1

11. Maintenance

Chapter Overview

This chapter contains maintenance requirements

and procedures for the following Rubber Track

Loader components.

• Grease fittings

• Engine oil

• Hydraulic fluid and filter

• Fuel separator and filter

• Track tension

• Air cleaner

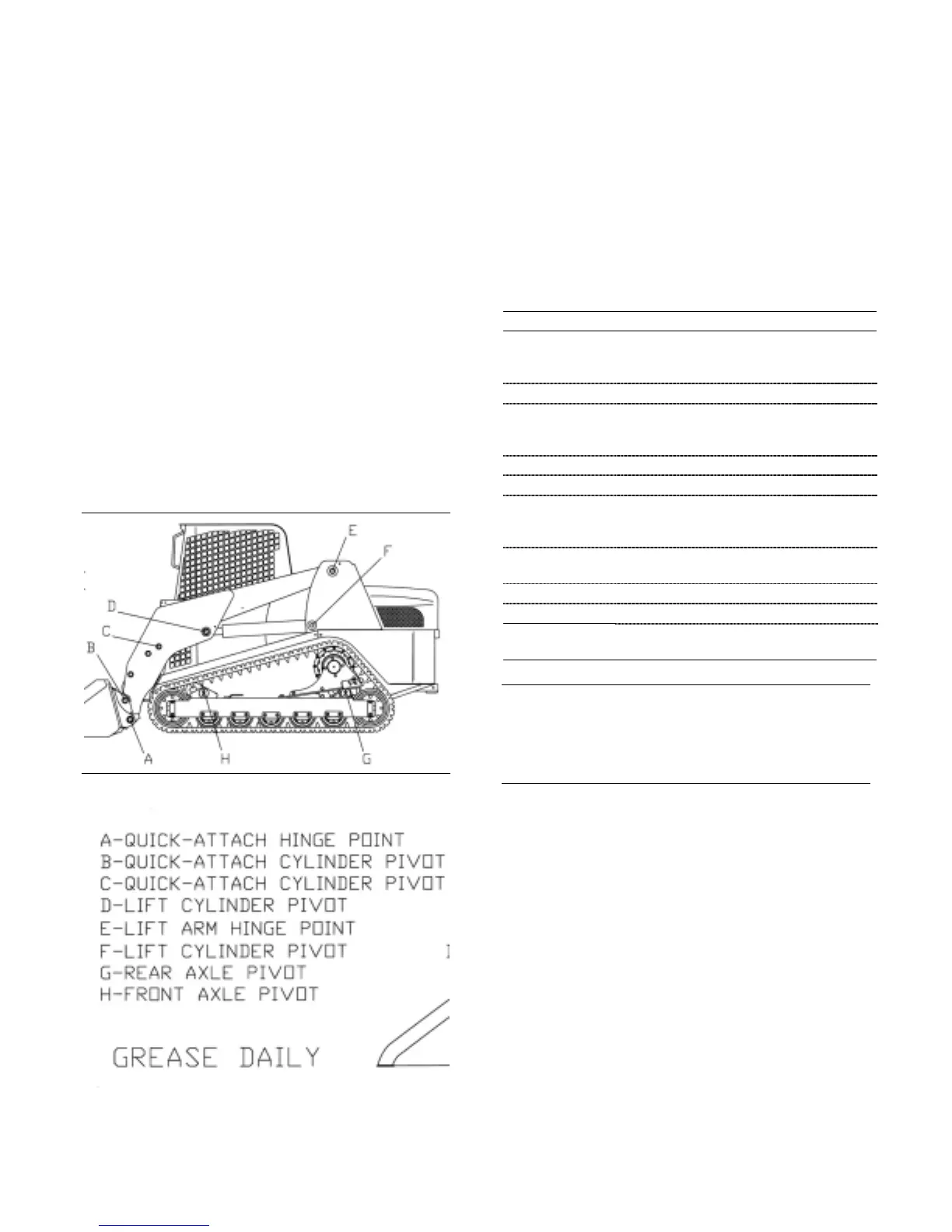

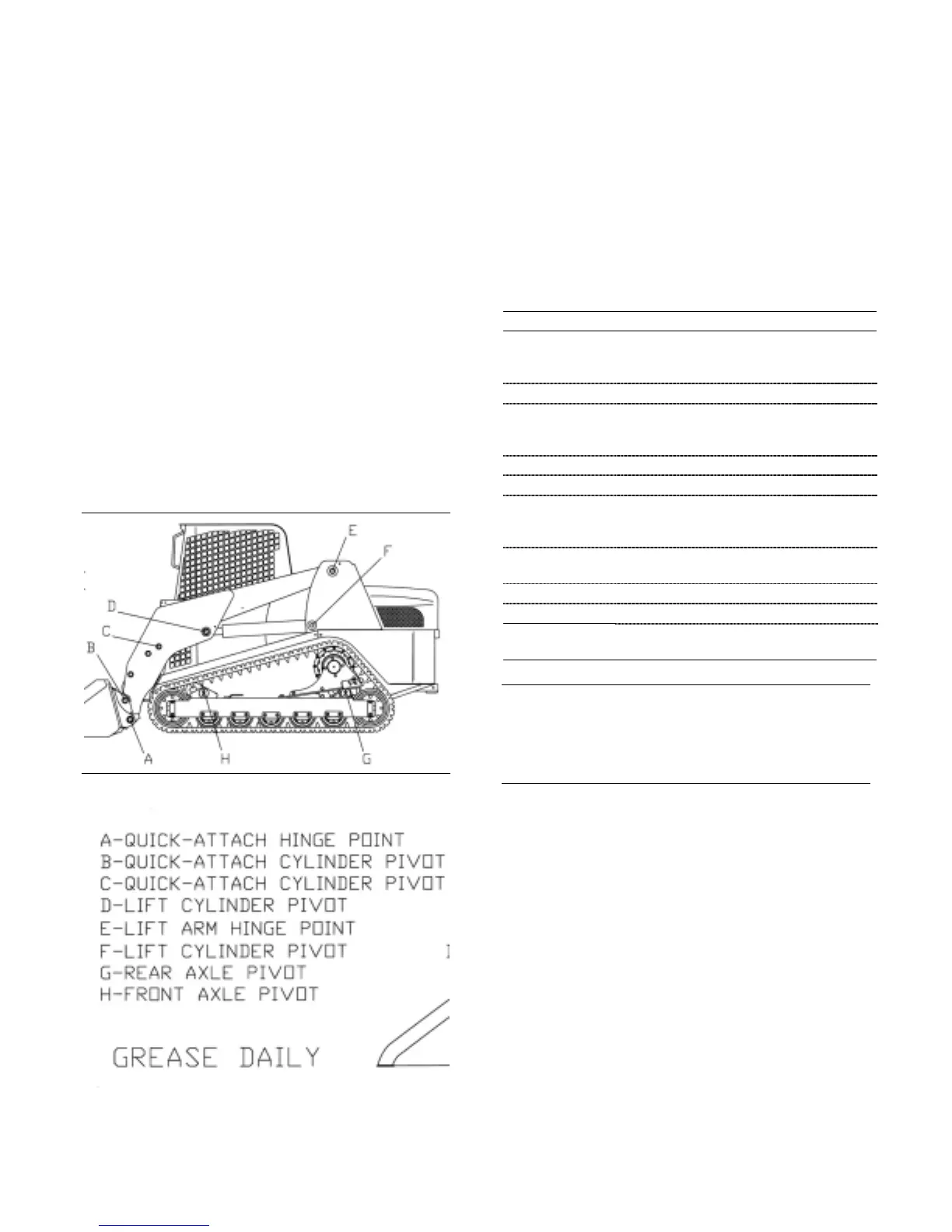

Grease Fitting Locations

Grease all Fittings daily

Maintenance Schedule

The general maintenance schedule for the Rubber

Track Loader is listed below.

Item Frequency Lubricant Capacity

Hydraulic Fluid 500 hrs

ASV Posi-Lube

Hydraulic Oil,

or Rykon MV

20 gal/75.7 l

Hydraulic Filters 250 hrs

Engine Oil 250 hrs

Posi-Lube HD

Diesel Engine

Oil, or other

8.5 qt / 8 l

Engine Filter 250 hrs

Fuel Filter 500 hrs

Primary Air

Filter

Check daily, clean and reuse as needed

up to 5 times; change at least once per

year

Secondary Air

Filter

Every 3 cleanings

of primary filter

Grease Fittings

8 hrs Posi-Lube Lithium Grease

Track Tension Break in, and then as needed

Coolant Test for coolant additive at 250 hrs.

Change at 1000 hrs or two years

NOTICE

When replacing engine coolant, use Posi-Lube Long Life

50/50 Antifreeze/Coolant, Caterpillar Extended Life Cool-

ant or equivalent antifreeze with the proper SCA

(Supplemental Cooling Additive)

Engine Oil

The normal oil change interval is every 250 service

hours or six months, whichever comes first. Engines

that are operated under severe conditions may need

the oil changed every 100 service hours or every 3

months, whichever comes first. Severe operating

conditions include: high temperatures, continuous

high loads and dusty conditions.

Loading...

Loading...