Checking the tensioning bolts

WARNING Rupturing washers become

projectiles

Washers can rupture and cause serious injuries, if

you hit the heads of the tensioning bolts or the

washers.

► Never check the tensioning bolts by acoustic test,

but by visual test.

The visual check is only an indication. You can only

check doubtless in a repair shop after removing the

adapter plate and the elastic pad.

♦

Remove the covers of the service openings which

are placed at the top of the breaker box’s rear

side.

♦

Check the seat of the paint marks which are

placed on the heads of the tensioning bolts and

washers.

The paint marks have to be in your visual field. In

other cases, the respective tensioning bolt can be

loose or broken. In this case act as follows:

♦

Dismount the adapter plate and the elastic pad

(see chapter Removing the adapter plate).

♦

Check the tensioning bolt for tight fit.

♦

Tighten the loose tensioning bolt with the torque

required. (see chapter Bolt connections/Tightening

torques).

♦

Strip the old paint mark.

♦

Mark new the tighten tensioning bolt, the washer

and the cylinder cover with a colour cast of 10 mm

width vertically over all three parts. The paint mark

shall be seen in the centre of the service openings.

♦

Have broken tensioning bolts immediately

replaced.

♦

If you have any questions about replacement of

broken tensioning bolts, consult the Atlas Copco

Customer Center/Dealer in your area.

You can only check the front tensioning bolts, if you

dismount the adapter plate and the elastic pad (see

chapter Removing the adapter plate).

♦

Check the tensioning bolts weekly for tight fit.

Checking the working tool

WARNING Hot working tool

The tip of the working tool gets very hot during

operation. Touching it may lead to burns.

► Never touch the hot working tool.

► If you have to carry out any activities, wait for the

working tool to cool down first.

♦

Remove the working tool (see the chapter

Dismantling the working tool).

♦

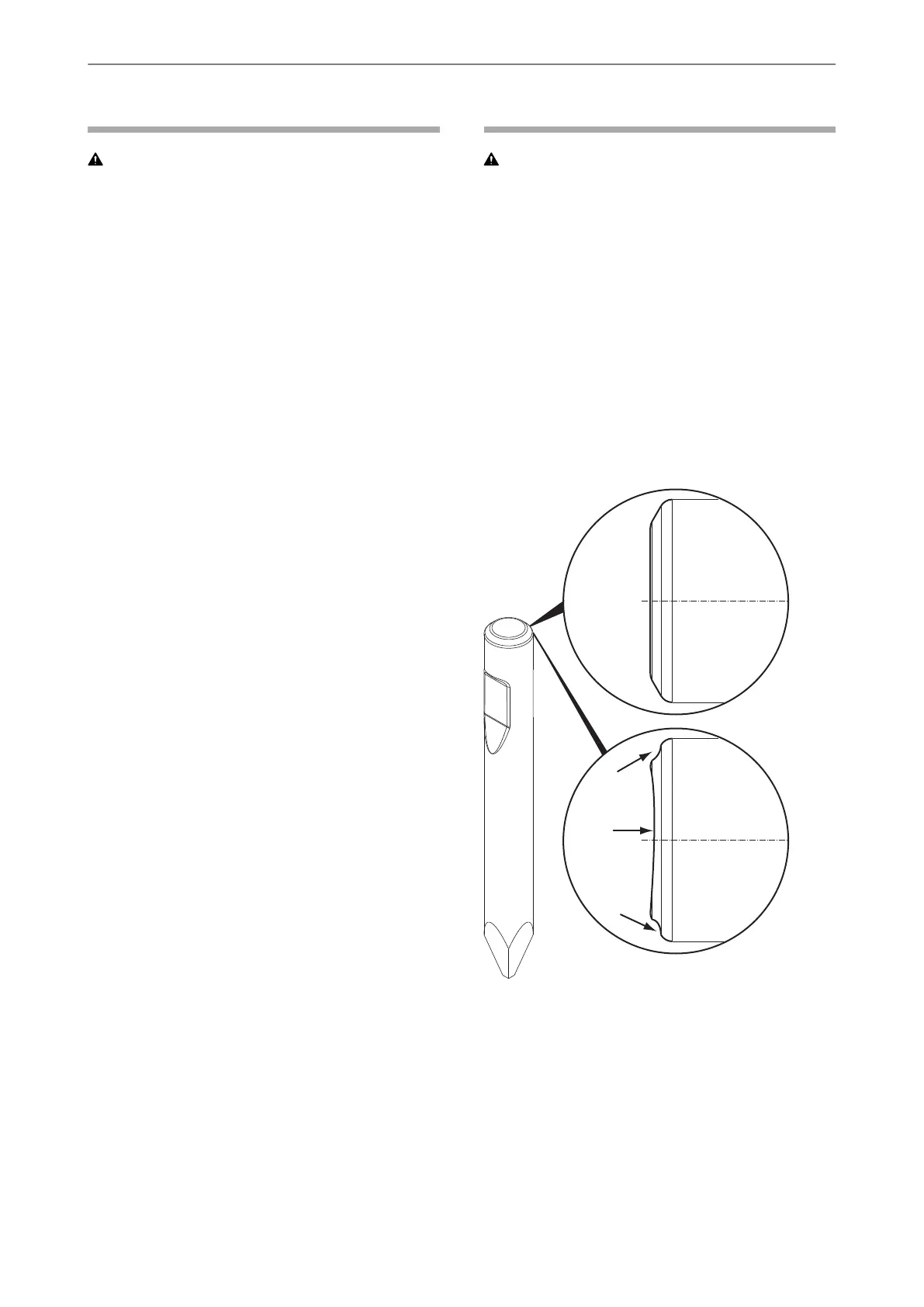

Check the impact surface of the working tool for

chips and cracks.

♦

Check the impact surface of the working tool for

deformation:

A = new working tool

B, C = worn working tool

♦

Replace the working tool if you detect chips,

cracks or deformations (B and C).

♦

Check the wear condition of the impact ring if you

detect deformations (B). Replace impact ring if

necessary.

47© 2012 Atlas Copco Construction Tools GmbH | No. 3390 5005 01 | 2012-05-03

Original instructions

MAINTENANCEHB 5800, 5800 DP, 7000, 7000 DP, 10000 DP

Loading...

Loading...