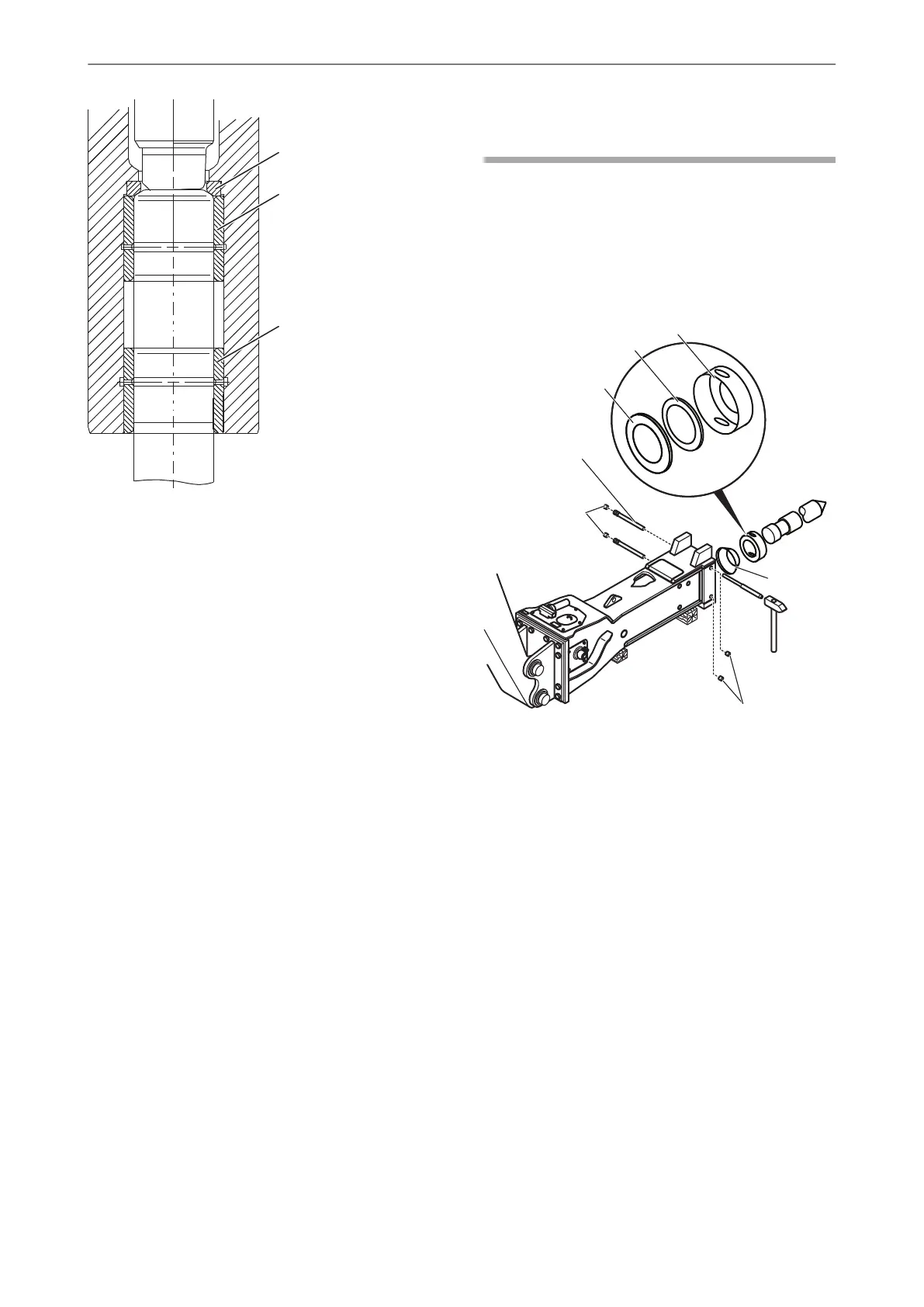

A. impact ring

B. upper wear bush

C. lower wear bush

The upper wear bush and the impact ring must be

replaced in a workshop fitted out for this purpose.

♦

Replace the lower wear bush when its inside

diameter is greater than the maximum permissible

diameter.

♦

When replacing the lower wear bush check the

inside diameter of the upper wear bush using

inside callipers (part number 3363 0949 52).

♦

Replace the upper wear bush and the impact ring

when the inside diameter is greater than the

maximum permissible diameter.

♦

Replace the buffer ring if you find chips and

cracks.

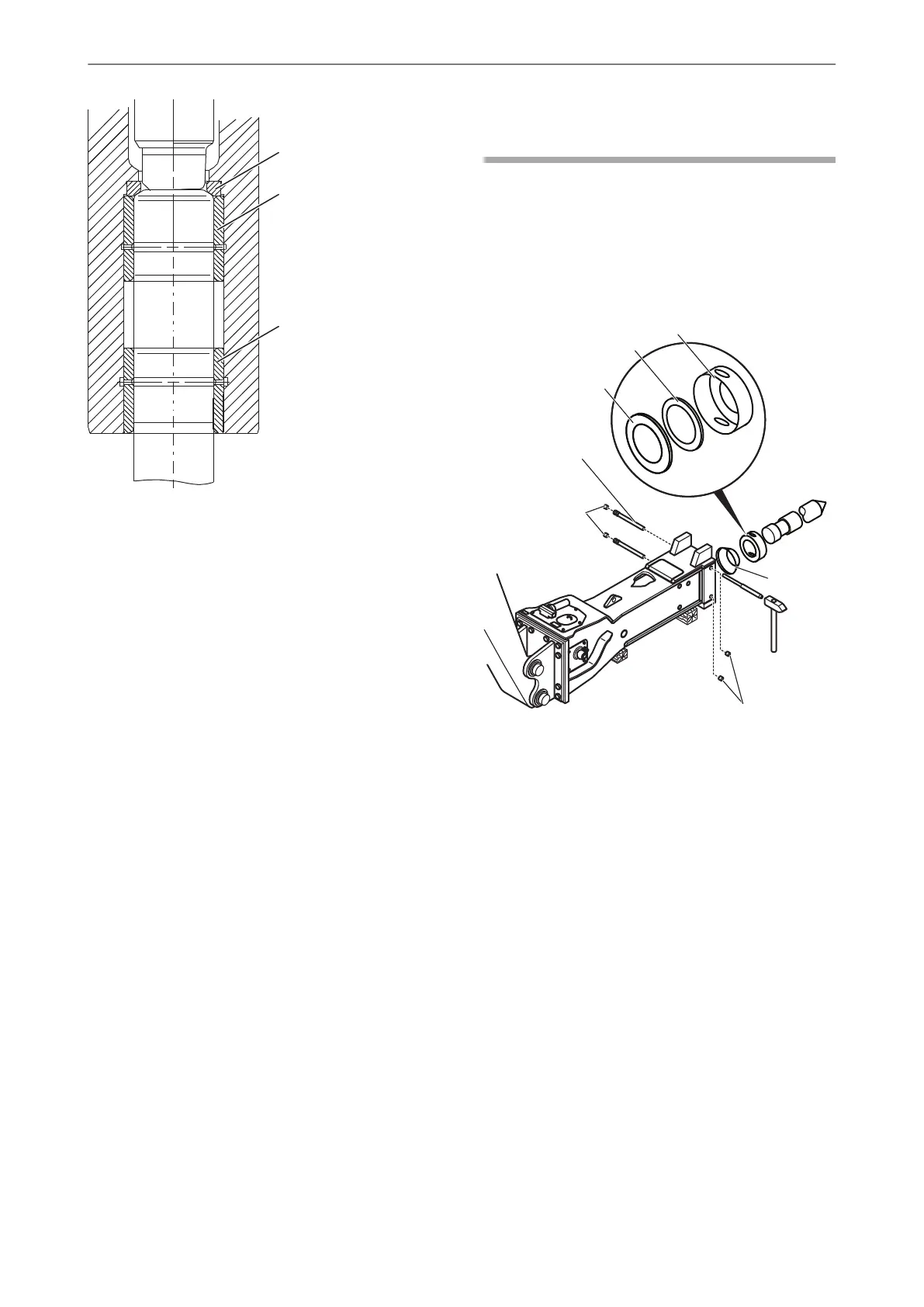

Checking and cleaning the

DustProtector system

An important factor for the DustProtector operation

is that the floating ring which moves in a radial

direction can follow the movements of the breaker

and the working tool.

If dust penetrates it, it may block up the available

installation space and interfere with the DustProtector

system operation.

♦

Regularly check that the floating ring (E) can move

freely.

NOTICE Environmental damage due to chisel paste

Chisel paste is environmentally harmful and must

not penetrate the ground or enter the water table or

water supplies.

► Dispose of chisel paste polluted by dust and of

cloths with chisel paste in accordance with the

applicable regulations to avoid environmental

hazards.

Regular cleaning and greasing of the installed parts

and their holders safeguards their operation and

improves the availability of the hydraulic breaker.

The inspection frequency depends on how much

dust is generated:

Normal dust generation:

once a week (assuming 40–50 hours of operation).

49© 2012 Atlas Copco Construction Tools GmbH | No. 3390 5005 01 | 2012-05-03

Original instructions

MAINTENANCEHB 5800, 5800 DP, 7000, 7000 DP, 10000 DP

Loading...

Loading...