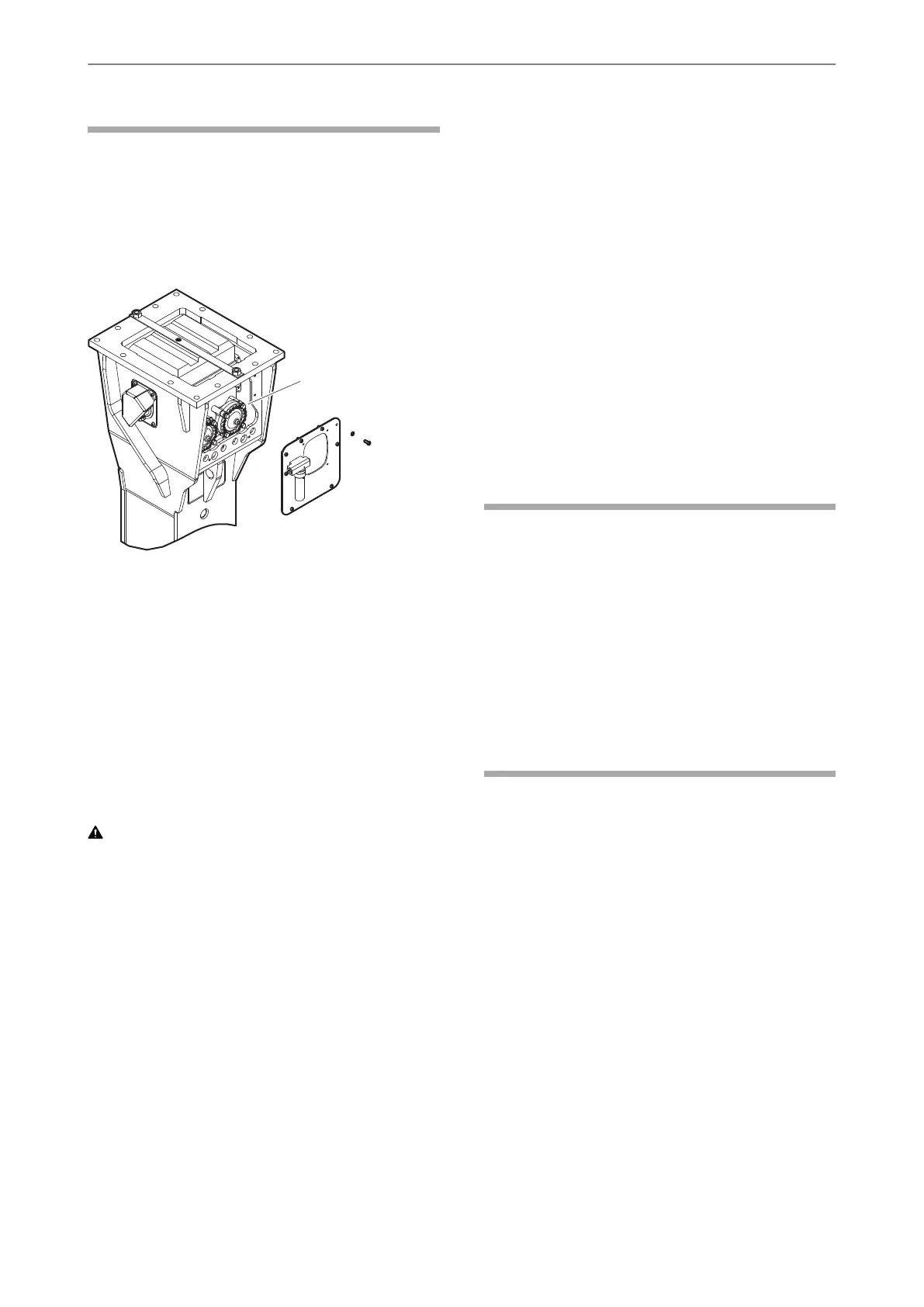

HP-accumulator

Accumulators are pressure containers in the context

of the European Pressure Equipment Directive

97/23/EC.

Checking the expansion bolts

Once a week, check that the HP-accumulator

expansion bolts are tight.

exact location may differ depending on breaker type

♦

Check that the expansion bolts (A) are tight.

♦

Tighten any loose bolts to the right tightening

torques (see chapter Bolt connections / Tightening

torques).

♦

If any of the HP-accumulator expansion bolts are

broken, replace all bolts.

If the pressure line »P« starts to flail violently there

is a problem with the HP-accumulator operation.

♦

Immediately stop the hydraulic breaker.

WARNING Component coming loose abruptly

The HP-accumulator is under pressure, even when

the hydraulic system has been depressurised. Screw

connections and parts of the HP-accumulator might

come loose abruptly and cause injuries.

► Never unscrew the cover or the upper shell from

a pressurised HP-accumulator.

► Have the HP-accumulator checked in accordance

with the national / regional safety provisions.

Checking the gas pressure

After the first installation of the hydraulic breaker, the

fill pressure of the HP-accumulator must be checked

at least once during the first week. If no loss of gas

is found, the second check is to be carried out after

three months. If no change in pressure is found at

that stage, then testing can be switched to annual.

Further checks, e.g. prior to installation and recurring

checks, are to be carried out in accordance with

national regulations.

♦

Check the gas pressure by using the accumulator

filling device.

♦

Follow the procedure in the respective operating

instructions.

The pre-fill pressure changes with the gas

temperature. After filling or releasing nitrogen, it is

necessary to wait until the temperature has levelled

before checking the gas pressure (20 °C).

♦

Replace the HP-accumulator if necessary.

Instructions on how to replace the HP-accumulator

is described in a seperate documentation.

♦

Before replacing the HP-accumulator, consult the

Atlas Copco Customer Center/dealer in your area.

Checking the hydraulic lines

♦

Before starting your work shift, always carry out

a visual check of all lines (pipes and hoses) from

the pump to the hydraulic attachment and from

there to the tank.

♦

Tighten any loose screw connections or hose

clamps.

♦

Replace damaged pipes and/or hoses.

Checking and cleaning the

hydraulic oil filter

An oil filter must be integrated in the tank line of the

hydraulic system. The maximum mesh width allowed

for the oil filter is 50 microns; it must have a magnetic

separator.

♦

Replace the oil filter cartridges after the first 50

operating hours.

♦

Check the oil filter every 500 operating hours and

replace as required.

53© 2012 Atlas Copco Construction Tools GmbH | No. 3390 5005 01 | 2012-05-03

Original instructions

MAINTENANCEHB 5800, 5800 DP, 7000, 7000 DP, 10000 DP

Loading...

Loading...