- 43 -

COOLANT CHECK

In order to guarantee the lifetime and

quality of the product, thus to optimise

engine protection, regular coolant-

condition-analysis is advisable.

The quality of the product can be

determined by:

Visual check

• Verify the outlook of the coolant

regarding colour and make sure that no

loose particles are floating around.

TOPPING UPCOOLANT

• Verify if the engine cooling system is in

a good condition (no leaks, clean,...).

• Check the condition of the coolant.

• If the condition of the coolant is outside

the limits, the complete coolant should

be replaced (see section Replacing the

coolant).

• Topping up the coolant with water only,

changes the concentration of additives

and is therefore not allowed.

REPLACING THE COOLANT

Drain

• Completely drain the entire cooling

system.

• Used coolant must be disposed or

recycled in accordance with laws and

local regulations.

Fill

• To assure proper operation and the

release of trapped air, run the engine

until normal engine operation

temperature is reached. Turn off the

engine and allow to cool.

• Recheck coolant level and add if

necessary.

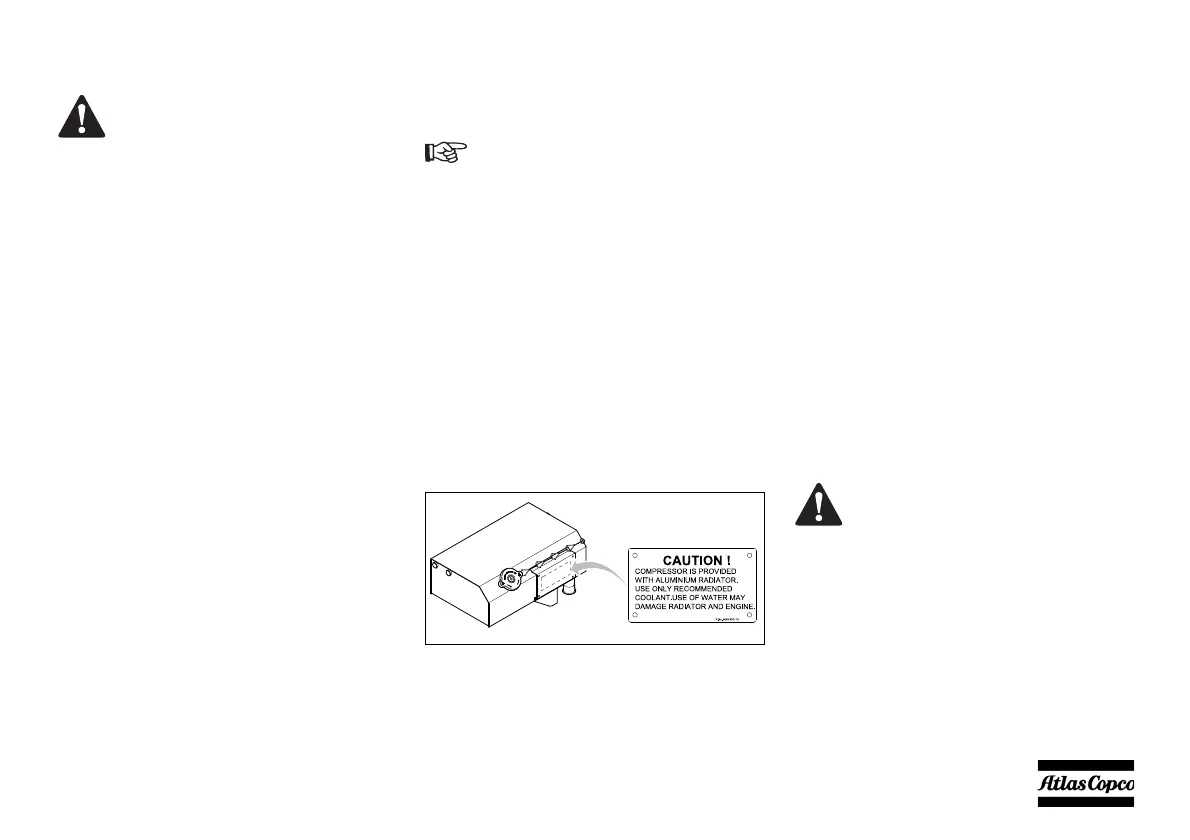

Never remove the cooling system

filler cap while coolant is hot.

The system may be under

pressure. Remove the cap slowly

and only when coolant is at

ambient temperature. A sudden

release of pressure from a

heated cooling system can result

in personal injury from the

splash of hot coolant.

For topping up / replacing

coolant consult engine operation

manual.

Caution: do not top off when the

engine is hot.

Loading...

Loading...