2. Slip handwheel [3] onto input shaft.

3. Secure handwheel [3] with retaining ring [4].

Information: The retaining ring [4] (together with these operation instructions)

is stored in a weatherproof bag, which is attached to the device prior to delivery.

4.4. Multi-turn actuator: mount to valve/gearbox

Corrosion due to damage to paint finish and condensation!

→

Touch up damage to paint finish after work on the device.

→

After mounting, connect the device immediately to electrical mains to ensure

that heater minimises condensation.

4.4.1. Stem nut for output drive type A: finish machining

This working step is only required if stem nut is supplied unbored or with pilot bore.

Information For exact product version, please refer to the order-related technical data sheet or

the AUMA Assistant App.

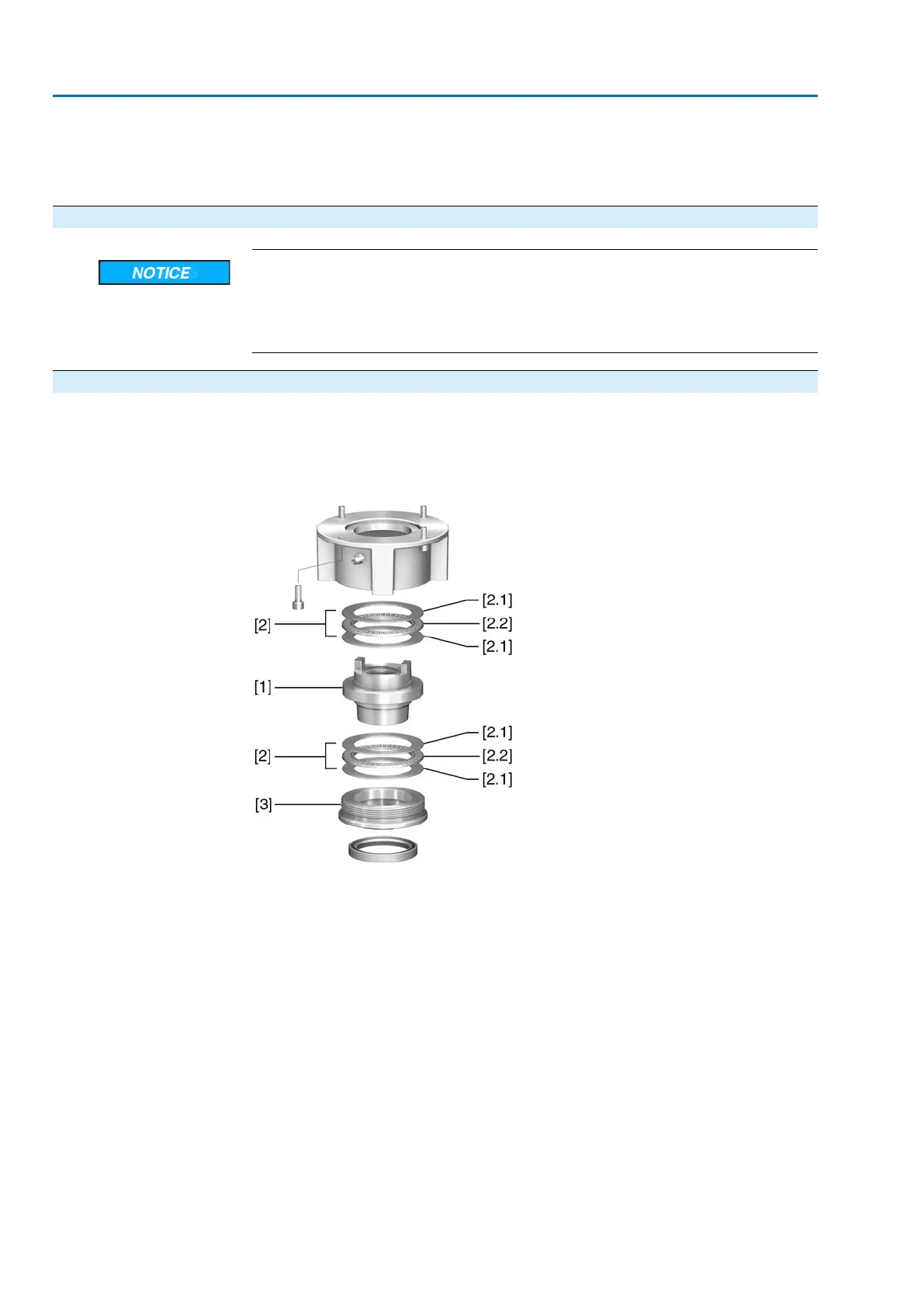

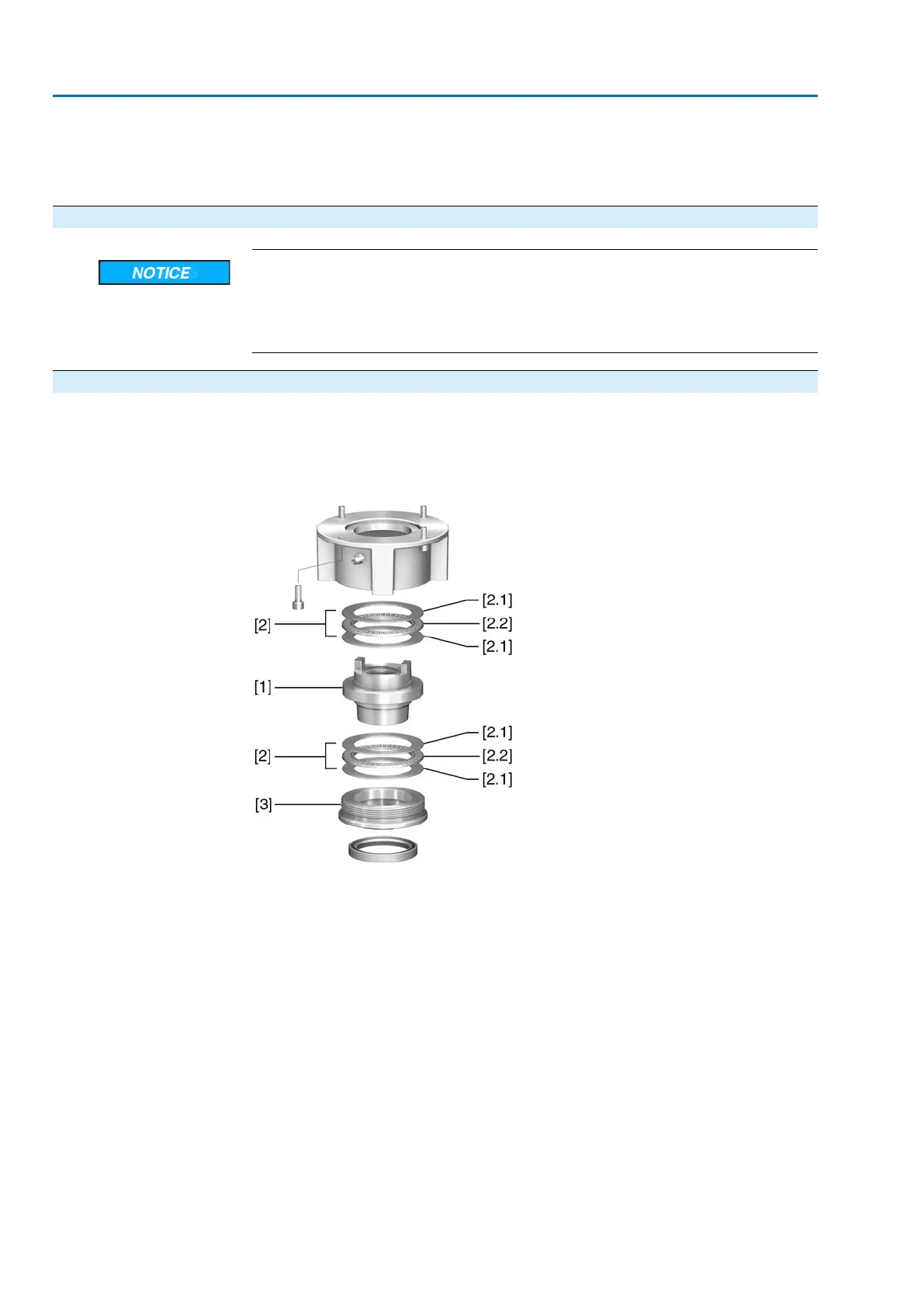

Figure 11: Output drive type A

[1] Stem nut

[2] Axial needle roller bearing

[2.1] Axial bearing washer

[2.2] Axial needle roller and cage assembly

[3] Spigot ring

Procedure

1. Remove spigot ring [3] from output drive.

2. Remove stem nut [1] together with axial needle roller bearings [2].

3. Remove axial bearing washers [2.1] and axial needle roller and cage assemblies

[2.2] from stem nut [1].

4. Drill and bore stem nut [1] and cut thread.

5. Clean the machined stem nut [1].

6. Apply sufficient Lithium soap EP multi-purpose grease to axial needle roller and

cage assemblies [2.2] and axial bearing washers [2.1], ensuring that all hollow

spaces are filled with grease.

7. Place greased axial needle roller and cage assemblies [2.2] and axial bearing

washers [2.1] onto stem nut [1].

18

SA 07.2 – SA 16.2 / SAR 07.2 – SAR 16.2 Control unit: electronic (MWG)

Assembly AC 01.2 Non-Intrusive EtherNet/IP

Loading...

Loading...