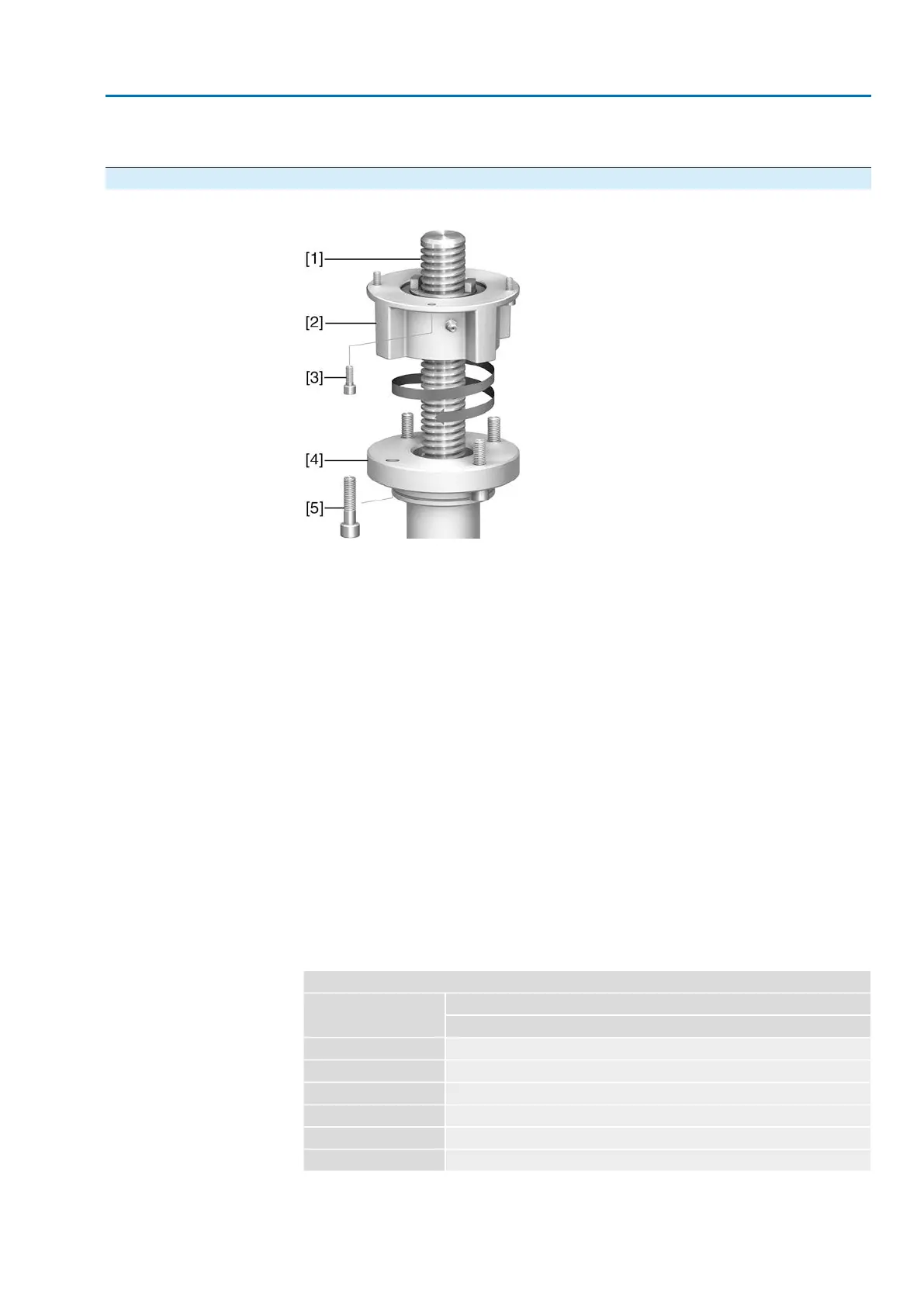

8. Re-insert stem nut [1] with axial needle roller bearings [2] into output drive.

9. Screw in spigot ring [3] until it is firm against the shoulder.

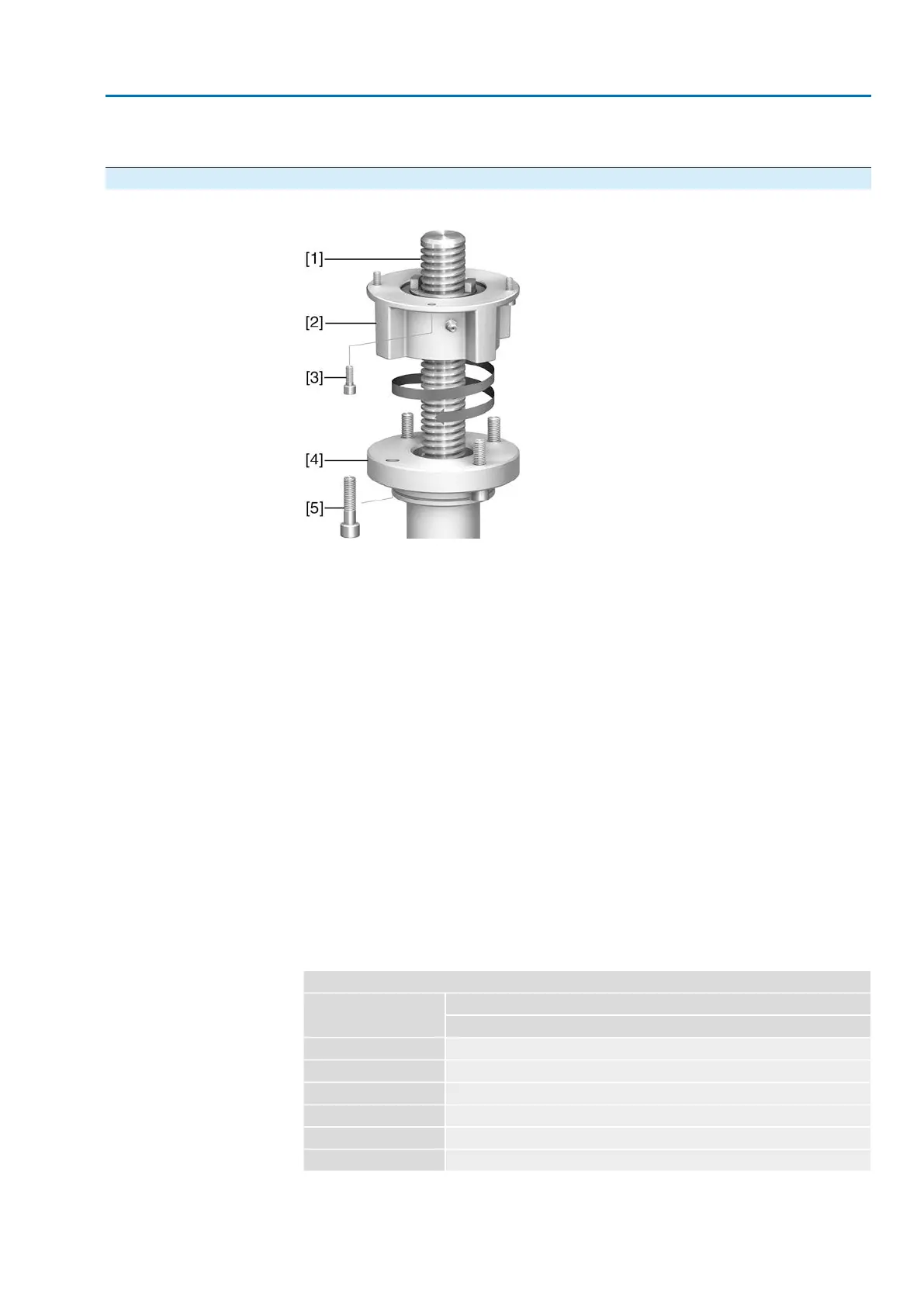

4.4.2. Multi-turn actuator with output drive type A: mount

Figure 12: Assembly of output drive type A

[1] Valve stem

[2] Output drive type A

[3] Screws to actuator

[4] Valve flange

[5] Screws to output drive

Procedure

1. If output drive type A is already mounted to the multi-turn actuator: Loosen

screws [3] and remove output drive type A [2].

2. Apply a small quantity of grease to the valve stem [1].

3. Place output drive type A on valve stem and turn until it is flush on the valve

flange.

4. Turn output drive type A until alignment of the fixing holes.

5. Screw in fastening screws [5], however do not completely tighten.

6. Fit multi-turn actuator on the valve stem so that the stem nut dogs engage into

the output drive sleeve.

➥

The flanges are flush with each other if properly engaged.

7. Adjust multi-turn actuator until alignment of the fixing holes.

8. Fasten multi-turn actuator with screws [3].

9. Fasten screws [3] crosswise with a torque according to table.

Table 11:

Tightening torques for screws

Tightening torque [Nm]Threads

Strength class A2-80/A4–80

10M6

24M8

48M10

82M12

200M16

392M20

10. Turn multi-turn actuator with handwheel in direction OPEN until valve flange

and output drive type A are firmly placed together.

19

SA 07.2 – SA 16.2 / SAR 07.2 – SAR 16.2 Control unit: electronic (MWG)

AC 01.2 Non-Intrusive EtherNet/IP Assembly

Loading...

Loading...