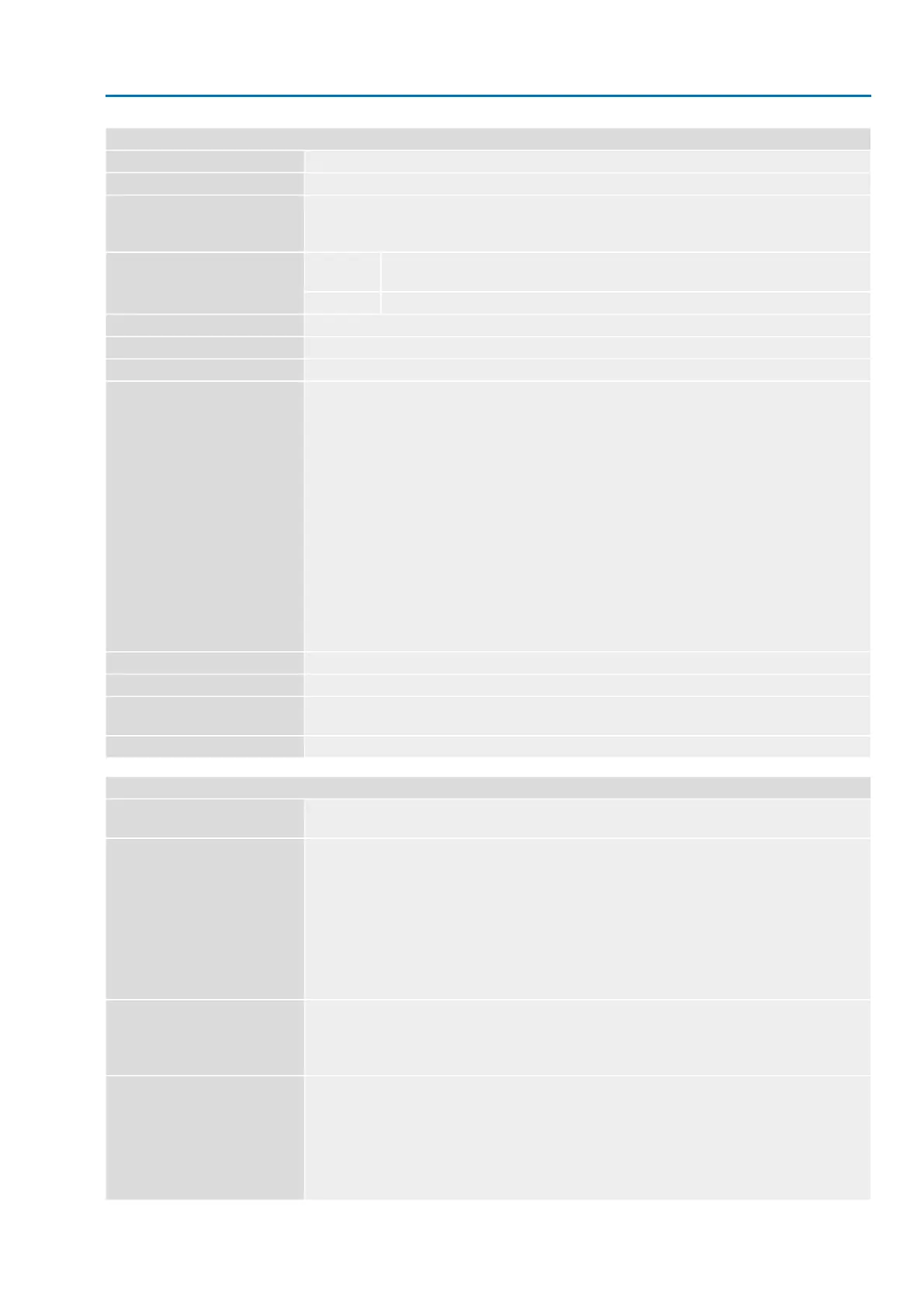

General data EtherNet/IP

EtherNet/IP according to IEC 61158 and IEC 61784Communication protocol

Star structure, point-to-point wiringNetwork topology

Ethernet IEEE 802.3

2-pair cabling in compliance with IEC 61784-5-3, cable recommendation: Cat. 6

A

Auto negotiation and auto crossover are supported.

Connection

1 x RJ-45, connection via connector for field assembly,

an RJ-45 connector for Cat.6 is supplied with the electrical connection.

Standard:EtherNet/IP connection

M12 connectionOption:

100 Mbits/s (100BASE-TX), full duplexTransmission rate

Max. 100 mCable length

Producer - Consumer modelFieldbus access

●

Data exchange based on generic I/O objects

●

Number of cyclic communication relations (Implicit Messages): 1

●

Number of acyclic connections (Explicit Messages): 6

●

I/O connection type: Exclusive-Owner, Cyclic

-

Originator to Target Type: POINT2POINT

-

Target to Originator Type: POINT2POINT, MULTICAST

●

Cyclic I/O communication (class1 connection):

-

Process representation input 46 bytes - Input Assembly Instance

-

Process representation output 14 bytes - Output Assembly Instance

●

Acyclic request/response communication (UCMM or class 3 connection):

-

Status information - Status Assembly Instance

-

Device configuration - Configuration Instance

-

Device identification - Identity Object

-

Network interface settings - TCP/IP Object

-

Ethernet information – Ethernet Link Object

Supported EtherNet/IP functions

0x0C = 12 - Communications AdapterEtherNet/IP device type

Generic DeviceCIP Device Profile

ARP (Address Resolution Protocol)

ICMP (Internet Control Message Protocol)

Supported network diagnostic and

management protocols

Via ESD fileDevice integration

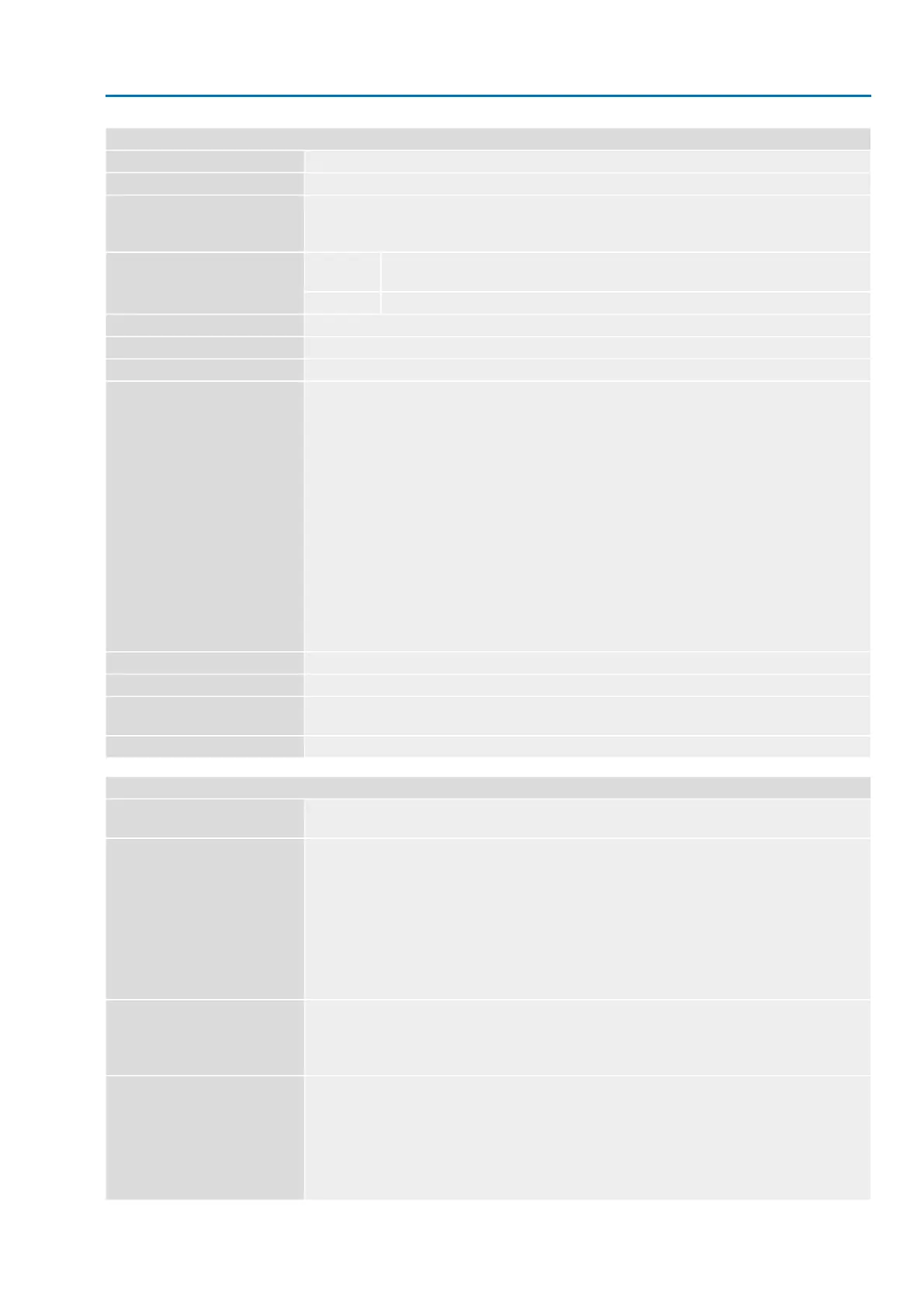

Commands and signals of the Ethernet IP interface

OPEN, STOP, CLOSE, position setpoint, RESET, EMERGENCY operation command, enable local

controls, Interlock OPEN/CLOSE

Process representation output

(command signals)

●

End positions OPEN, CLOSED

●

Actual position value

●

Actual torque value, requires magnetic limit and torque transmitter (MWG) in actuator

●

Selector switch in position LOCAL/REMOTE

●

Running indication (directional)

●

Torque switches OPEN, CLOSED

●

Limit switches OPEN, CLOSED

●

Manual operation by handwheel or via local controls

●

Analogue (2) and digital (4) customer inputs

Process representation input

(feedback signals)

●

Motor protection tripped

●

Torque switch tripped in mid-travel

●

One phase missing

●

Failure of analogue customer inputs

Process representation input

(fault signals)

The behaviour of the actuator is programmable:

●

Stop in current position

●

Travel to end position OPEN or CLOSED

●

Travel to any intermediate position

●

Execute last received operation command

Connection status between EtherNet/IP interface and actuator logic can be acyclically read within the

device.

Behaviour on loss of communication

89

SA 07.2 – SA 16.2 / SAR 07.2 – SAR 16.2 Control unit: electronic (MWG)

AC 01.2 Non-Intrusive EtherNet/IP Technical data

Loading...

Loading...