Cable installation in ac-

cordance with EMC

Signal and fieldbus cables are susceptible to interference. Motor cables are

interference sources.

●

Lay cables being susceptible to interference or sources of interference at the

highest possible distance from each other.

●

The interference immunity of signal and fieldbus cables increases if the cables

are laid close to the earth potential.

●

If possible, avoid laying long cables and make sure that they are installed in

areas being subject to low interference.

●

Avoid parallel paths with little cable distance of cables being either susceptible

to interference or interference sources.

HART cable recommend-

ation:

Twisted wire pair, shielded.

For cable length <1,500 m: Cross section min. 0.2 mm²

For cable length >1,500 m: Cross section min. 0.5 mm²

Multiple-twisted pair cables must not be used.

Prior to installation, please note:

●

Connection is made as point-to-point topology.

●

Respect a distance of minimum 20 cm between HART cables and other cables

if possible. The cables should be laid in a separate, conductive, and earthed

cable tray, if possible.

●

Make sure that there are no potential differences between participants.

●

Maximum cable length depends on characteristics of devices connected (im-

pedance), of cables used (cable capacity and resistance) and the impedance

of all devices installed between two end devices.

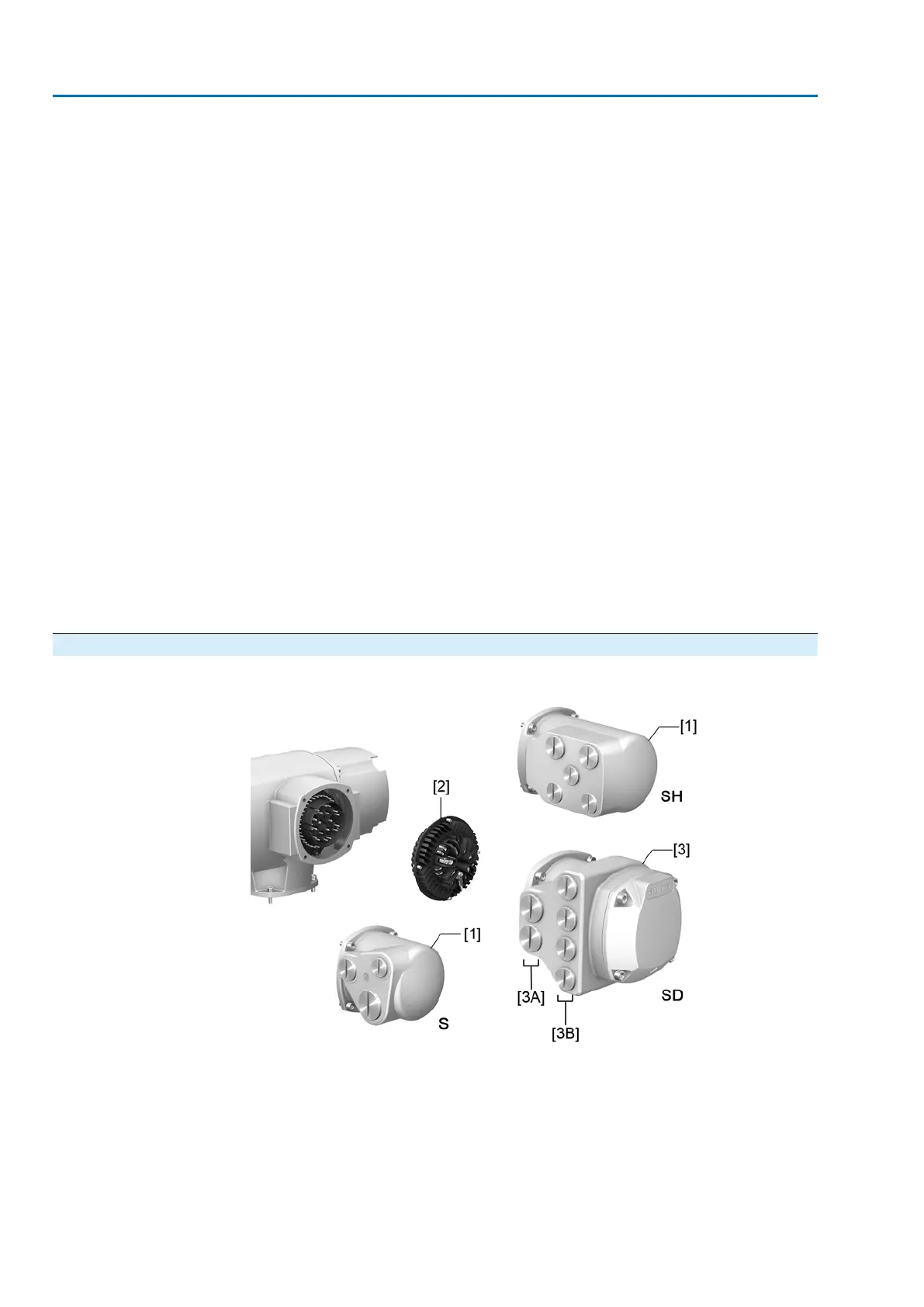

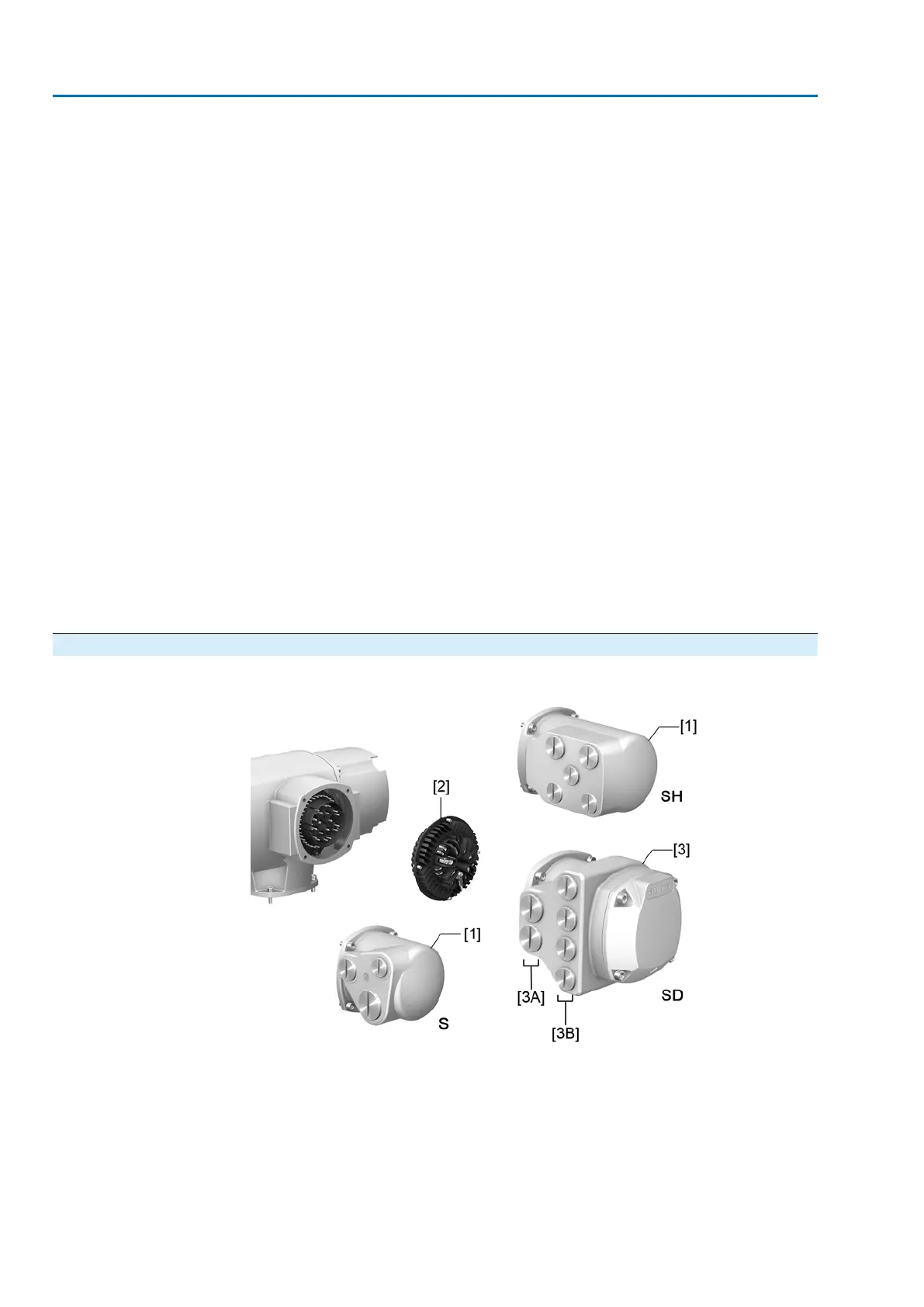

5.2. S/SH/SD electrical connection (AUMA plug/socket connector)

Figure 18: S, SH and SD electrical connection

[1] Cover

[2] Socket carrier with screw-type terminals

[3] Terminal compartment (in cover)

[3A] Cable entries for mains connection (pins for motor and pins for controls)

[3B] Cable entries for HART cables

Short description

Plug-in electrical connection with screw-type terminals for pins for motor and pins

for controls. Pins for controls also available as crimp-type connection as an option.

24

SA 07.2 – SA 16.2/SAR 07.2 – SAR 16.2 Control unit: electronic (MWG)

Electrical connection AC 01.2 Non-Intrusive HART

Loading...

Loading...