ZoneLogix™ PRO Zone Controller User Guide | Revision 1.0 November 2019 | Page 6

1

Introduction

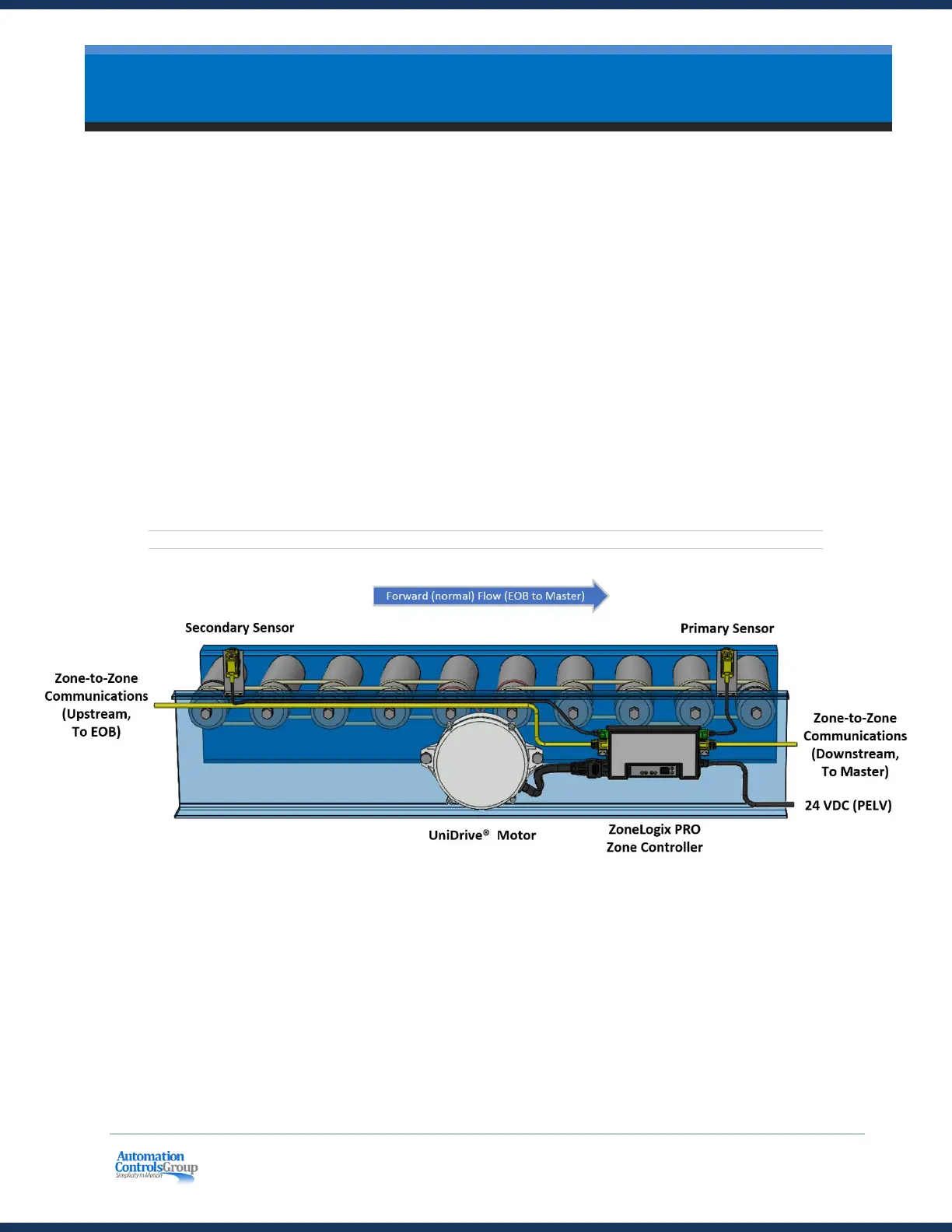

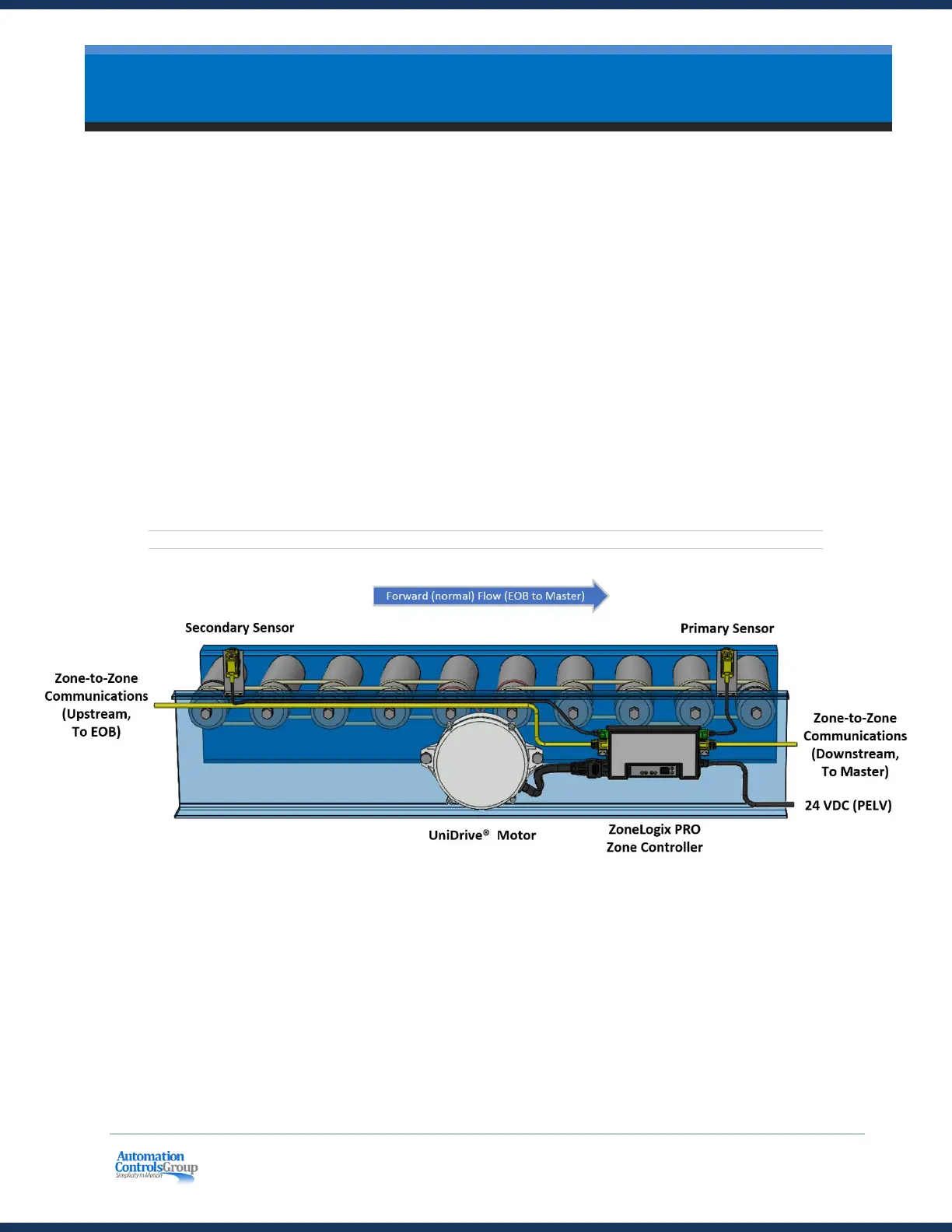

The ZoneLogix™ PRO Smart Conveyor System is a product that is used in material handling conveyance

applications. The system is comprised of two main components: Zone Controllers and the Branch

Monitor. A typical application consists of some length of roller conveyor (a Branch), divided into zones.

Each zone has a Zone Controller that controls a Brushless DC (BLDC) motor, or solenoid air actuator.

Zone Controllers communicate via a high-speed network. The Branch Monitor provides three different

functions: (1) It acts as a system monitor to allow for monitoring the operation of the Branch, (2) it acts

as a device to configure the behavior of the individual zones, and (3) it provides an EtherNet/IP fieldbus

interface for use with a Programmable Logic Controller (PLC).

ZoneLogix™ PRO was designed to provide levels of operation ranging from basic speed and direction to

advanced sophisticated implementations.

▪ Basic Mode: Everything your smart conveyor system needs to get started is already built-into the

ZoneLogix™ PRO system. You can connect up to 255 package-handling segments, or zones, in series

with one UniDrive

®

motor per zone.

▪ Advanced Mode: By adding the ZoneLogix™ PRO Branch Monitor, you can configure each individual

zone according to the needs of the application. Optionally, you can also connect a PLC to further

leverage the networking power of the ZoneLogix™ PRO to provide automated package tracking and

sophisticated control capabilities. You can connect up to 120 zones in a Branch. Multiple Branches

can be connected to each other.

Figure 1: The ZoneLogix™ PRO System

Loading...

Loading...