PAGE 65

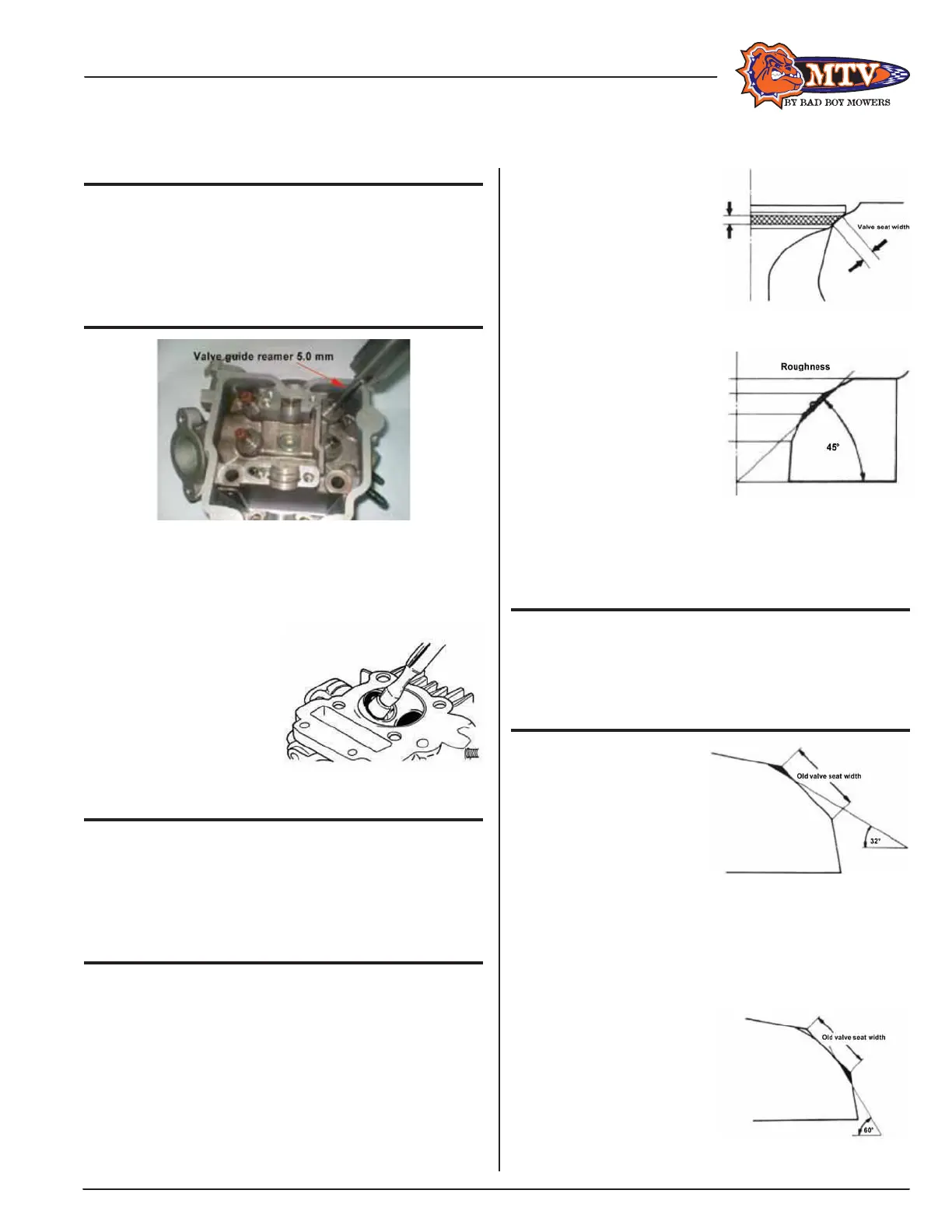

CAUTION

• Use cutting oil when correcting valve guide

with a reamer.

• Turn the reamer in same direction when

inserting or rotating.

• Correct valve seat, and clean up all metal residues

from cylinder head.

Valve Seat Inspection and Service:

• Clean up all carbon

deposits on intake and

exhaust valves.

• Polish valve face

lightly with emery.

• Grind valve seat with

manual grinding tool.

CAUTION

• Do not let emery enter between valve stem and

valve guide.

• Clean up the emery after corrected, and apply

engine oil onto contact faces of valve and valve seat.

• Remove the valve and check its contact face.

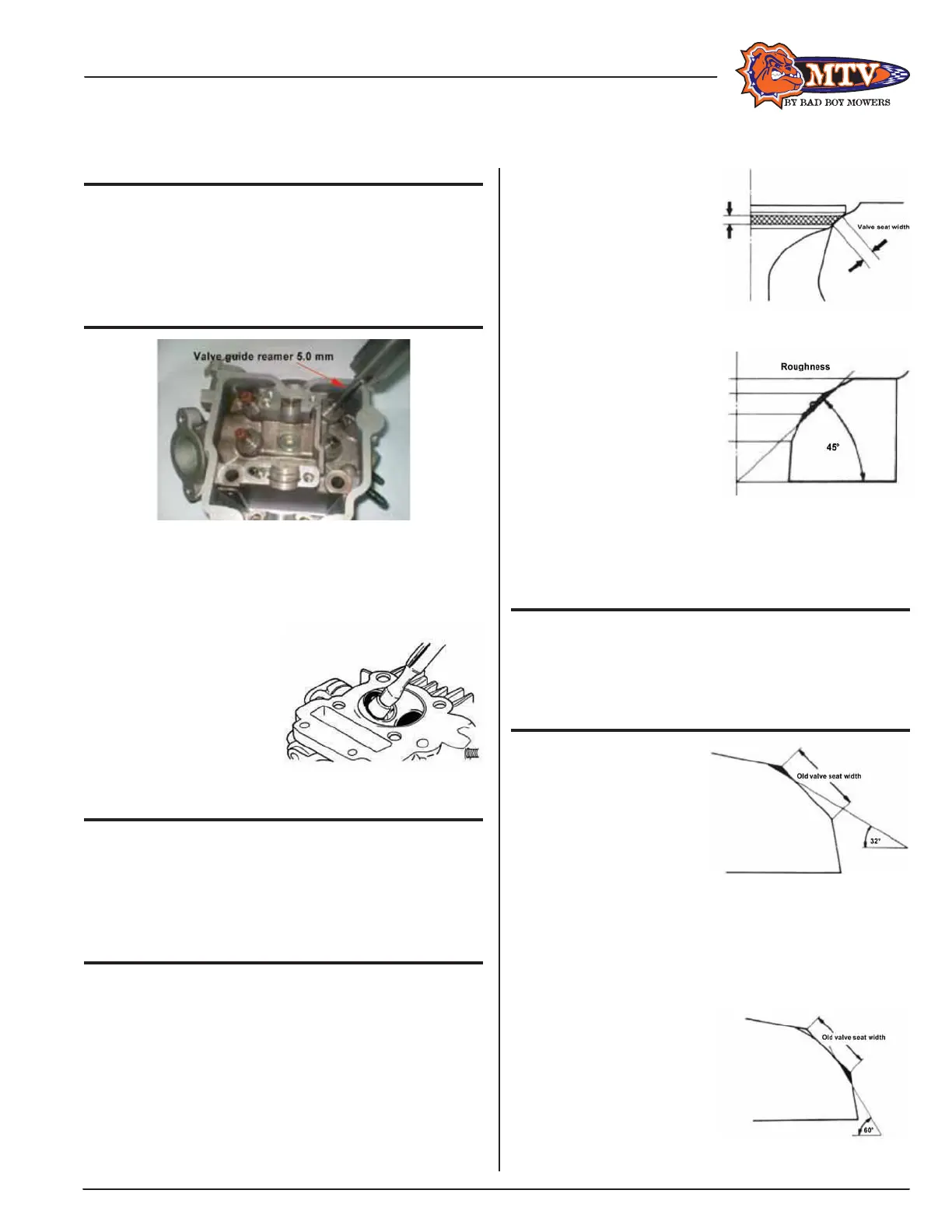

Valve seat inspection:

• If the valve seat is too wide, narrow or rough,

it needs correcting.

Valve seat width:

Service limit: 1.6mm

• Check the contact

condition of valve seat.

Valve seat grinding:

• The worn valve seat has

to be ground with valve

seat chamfer cutter.

• Refer to operation

manual of the valve seat

chamfer cutter.

• Use 45° valve seat chamfer cutter to cut any rough

or uneven surface from valve seat.

CAUTION

• After valve guide has been replaced, it has to

be ground with 45° valve seal chamfer cutter to

correct its seat face.

• Use 32° cutter to cut

upper part.

Valve Seat Inspection and Service:

• Use 60° cutter to cut lower parts out.

• Remove the cutter and check new valve seat.

• Use 45° cutter to grind

the valve seat to

specified width.

Loading...

Loading...