Using the Optional Insertion/Extraction Tool

Page 13 June 2018 VRX-UM-02217-EN-04

Using the Tool to Remove a Meter

BURN HAZARD. THE PROBE MAY BE HOT TO THE TOUCH IF THE FLUID IS HOT.

Attach the tool to the insertion meter:

1. Holding the back of the tool, place the tool behind the meter with the bottom (larger) clamp assembly in line with the

meter’s seal assembly.

2. Place the clamp cradles, with the bottom (larger) clamp assembly around the meter’s seal assembly, just below the

machined step on the seal, and the upper (smaller) clamp assembly around the meter shaft, 2 in. down from the top of

the shaft.

3. Secure the tops of the clamp assemblies to the cradles with the bolts provided.

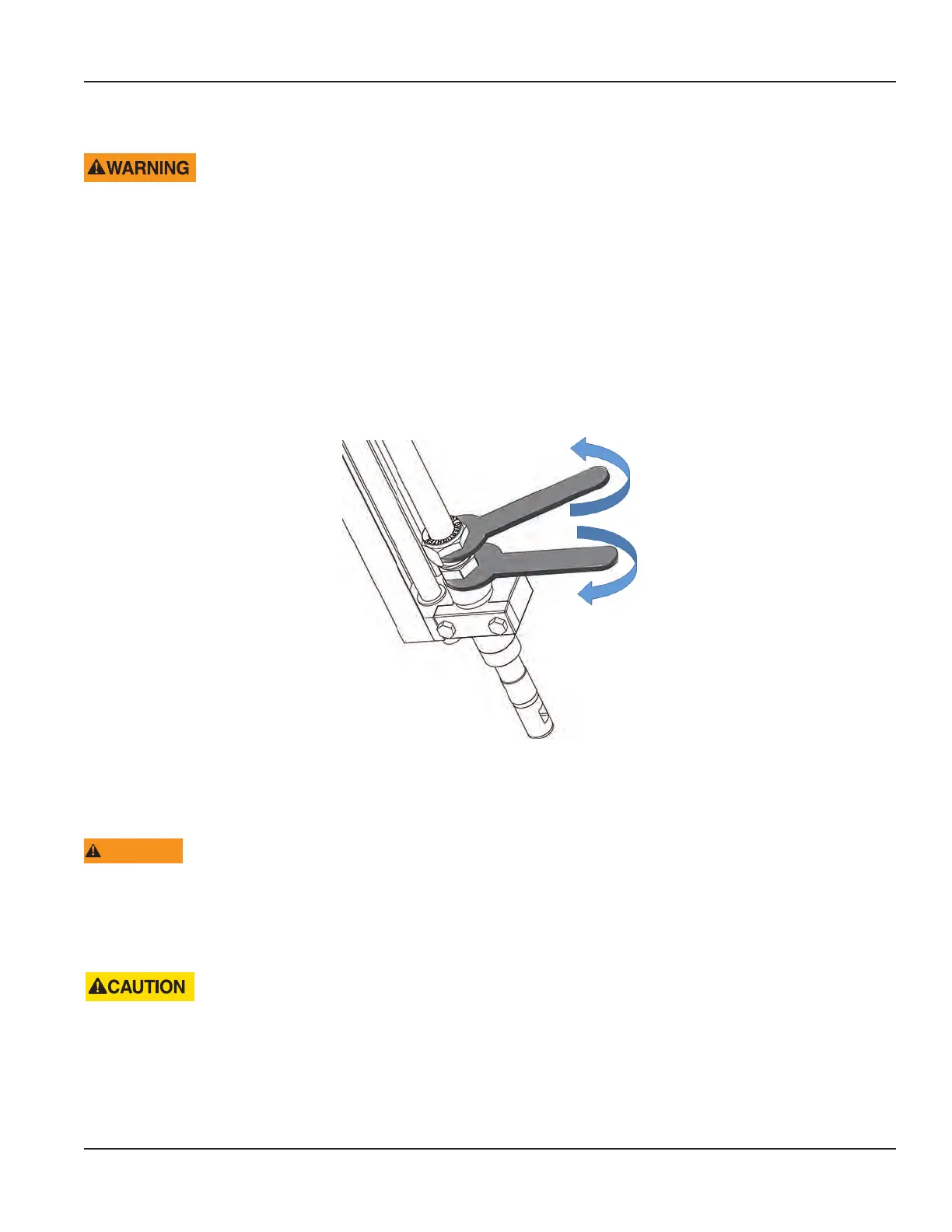

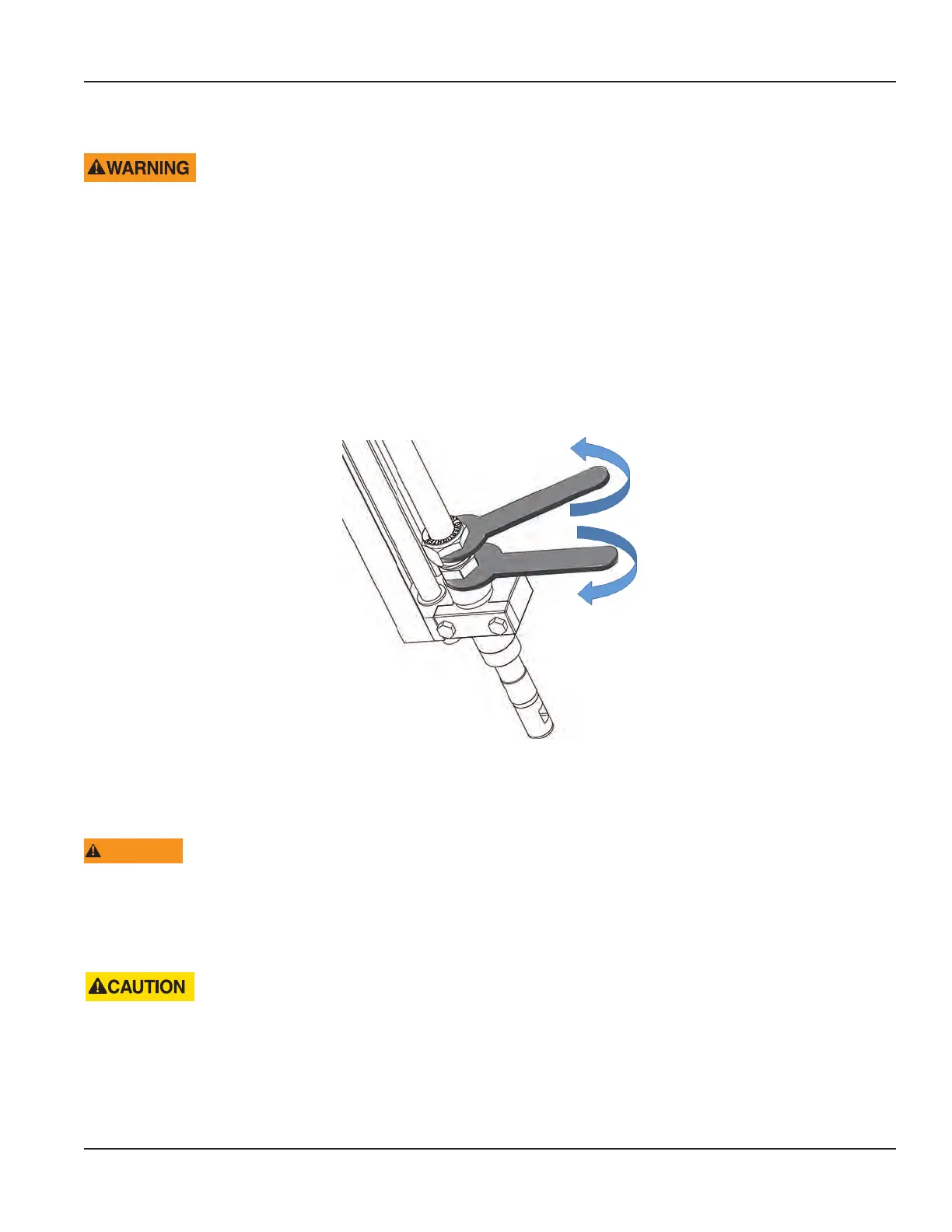

MPORTANTI

To make sure the seal assembly does not turn while the large hex nut is loosened, use two wrenches. Turn the wrench on the seal

assembly clockwise as you turn the wrench on the hex nut counterclockwise.

Figure 6: Removing the hex nut

4. Loosen the large hex nut and split ring (you may have to tap the nut with a hammer to free the split ring).

5. Completely back off the hex nut from the threads.

WTRNING

AFTER THE NUT IS COMPLETELY REMOVED, THE PRESSURE IS AGAINST THE INSERTION TOOL. DO NOT STAND IN THE

DIRECTION OF EXTRACTION AS PERSONAL INJURY COULD OCCUR.

7. Attach a wrench or a 1-1/8 in. socket wrench to the top of the threaded spindle of the insertion tool and turn the spindle

until the sensing element is extracted from the pipe and retracted up into the seal assembly.

MAKE SURE THE METER IS WELL PAST THE VALVE AND INTO THE SEAL ASSEMBLY BEFORE TRYING TO CLOSE

THE VALVE. IF FLOW METER SENSOR IS STILL IN THE VALVE WHILE IT IS BEING CLOSED, DAMAGE CAN OCCUR TO THE

SENSOR ELEMENT.

8. Close and purge the valve.

9. Remove the seal assembly slowly. There may be an amount of pressurized uid in the nipple, or the valve may not be

sealing properly.

Loading...

Loading...