10 english

4.4 Electrical connection

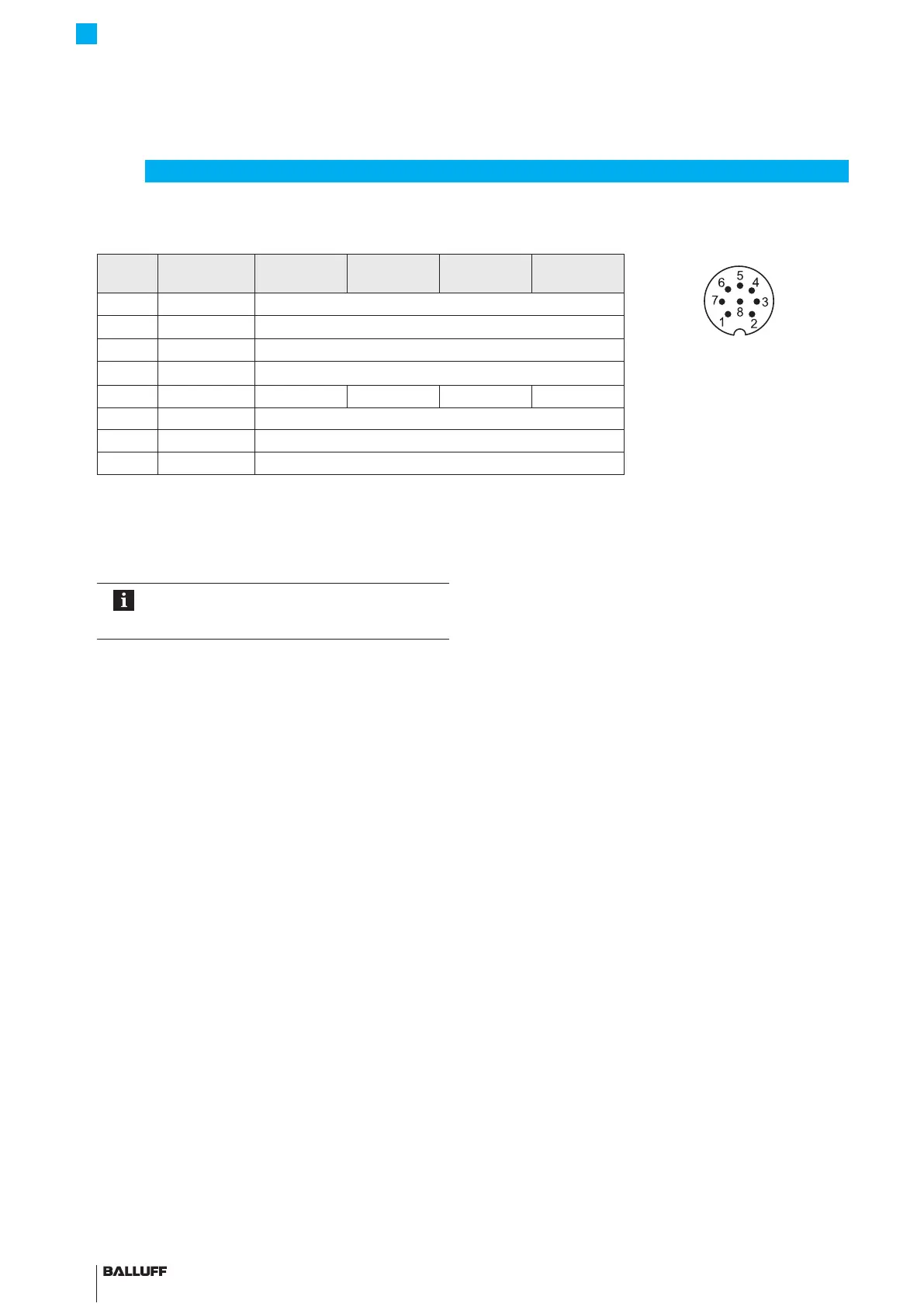

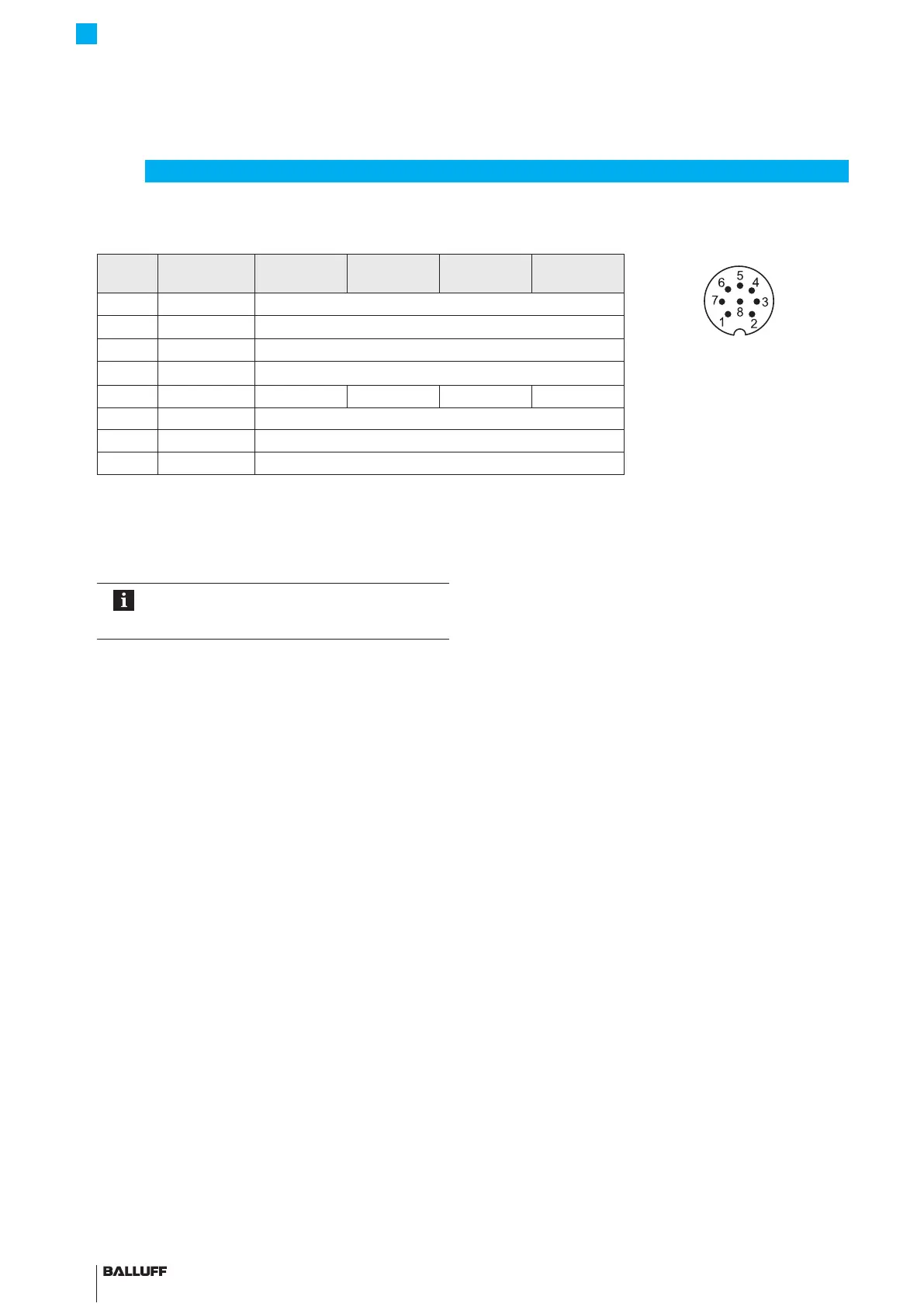

Pin BKS-S115-...

BKS-S116-...

-A500 -G500 -C500 -E500

Fig.4-8: Pin assignment of S115

connector (view of connector

pins of transducer)

1 Yellow Not used

1)

2 Gray 0V

3 Pink Not used

1)

4 Red La (programming input)

5 Green 0…10V −10…10V 0.1…20mA 4…20mA

6 Blue GND

2)

7 Brown 10…30V

8 White Lb (programming input)

1)

Unassigned leads can be connected to the GND on the controller side but not to the shield.

2)

Reference potential for supply voltage and EMC-GND.

Tab. 4-2: Pin assignment of S115 connector

4.5 Shielding and cable routing

Defined ground!

The transducer and the control cabinet must be

at the same ground potential.

Shielding

To ensure electromagnetic compatibility (EMC), observe

the following:

– Connect transducer and controller using a shielded

cable.

Shield: Braided copper shield with minimum 85%

coverage.

– Shield is internally connected to connector housing.

Magnetic fields

The position measuring system is a magnetostrictive

system.

It is important to maintain adequate distance between the

transducer and strong, external magnetic fields.

Cable routing

Do not route the cable between the transducer, controller,

and power supply near high voltage cables (inductive stray

noise is possible).

Inductive stray noise from AC harmonics (e.g.from phase

angle controls) are especially critical and the cable shield

offers very little protection against this.

Cable length

Cable length max.20m. Longer cables may be used if

their construction, shielding and routing prevent noise

interference.

4

Installation and connection (continued)

Noise elimination

To avoid equipotential bonding - a current flow - through

the cable shield, please note the following:

– Use insulating bushes

– Put the control cabinet and the system in which the

BTL6 is located to the same ground potential.

BTL6-A/C/E/G500-M _ _ _ _ -PF-S115

Micropulse Transducer in a Flat Profile Housing

Loading...

Loading...