www.balluff.com 7english

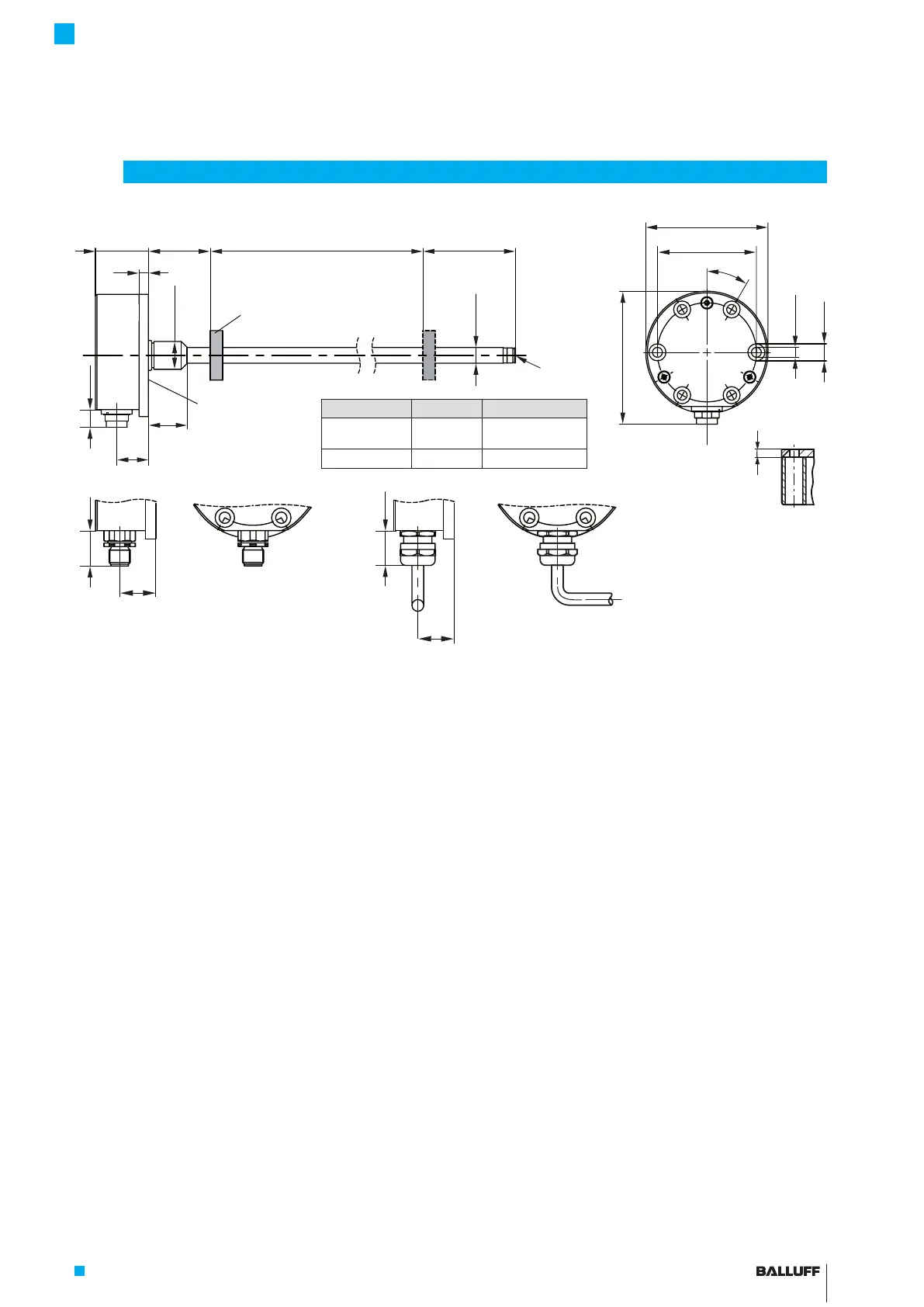

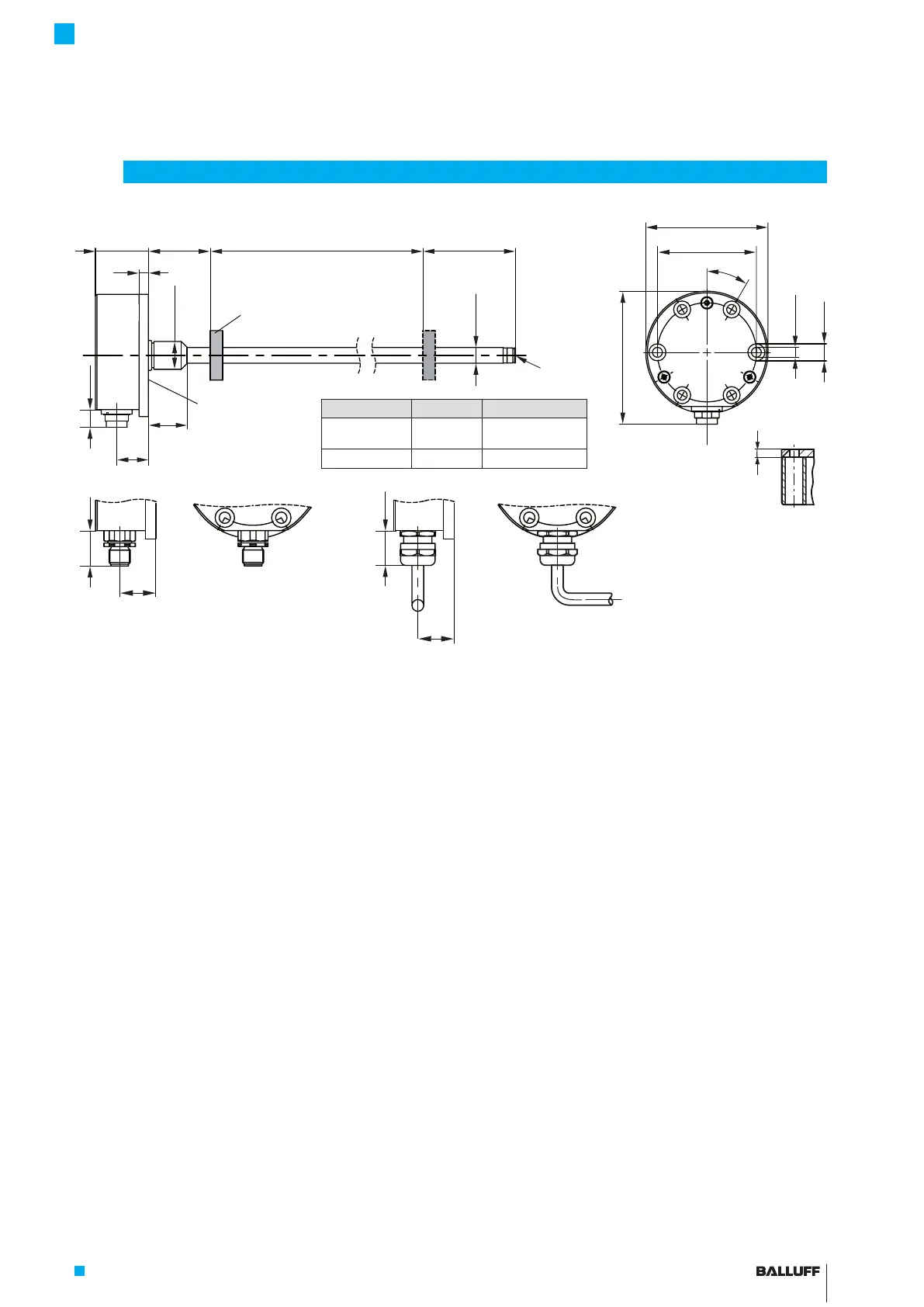

Fig. 3-1:

30°

34 40-1

6

Ø D1

Ø 18 h6

60

25

20.5

G

Ø 64

Ø 6.4

Ø 11

86

20.5

20.5

~18

6

Version D1 G

…-K-… 10.2 mm Thread

M4x4/6deep

…-K8-… 8 mm No thread

BTL7-…-K(8)-… transducer, construction and function

3.1 Construction

Electrical connection: The electrical connection is made

via a cable or a connector (see Type code breakdown on

page25).

Housing: Housing containing the processing electronics.

Fastening: For secure fastening, tighten the transducer

with cylinder screws (ISO4762, M6×16-A2-70) at all

6mounting holes (see Fig. 3-1). All screws must be

tightened with 3.5Nm.

The transducers with Ø 10.2 mm have an additional thread

at the end of the rod to support larger nominal lengths.

Magnet: Defines the position to be measured on the

waveguide. Magnets are available in various models and

must be ordered separately (see Accessories on

page22).

Nominal length: Defines the available measuring range.

Rods with various nominal lengths from 25 mm to

7620mm are available depending on the version:

– Ø10.2mm: Nominal length from 25mm to 7620mm

– Ø8mm: Nominal length from 25mm to 1016mm

Damping zone: Area at the end of the rod that cannot be

used for measurements, but which may be passed over.

3.2 Function

The Micropulse Transducer contains the waveguide which

is protected by an outer stainless steel tube (rod). A

magnet is moved along the waveguide. This magnet is

connected to the system part whose position is to be

determined.

The magnet defines the position to be measured on the

waveguide.

An internally generated INIT pulse interacts with the

magnetic field of the magnet to generate a torsional wave

in the waveguide which propagates at ultrasonic speed.

The component of the torsional wave which arrives at the

end of the waveguide is absorbed in the damping zone to

prevent reflection. The component of the torsional wave

which arrives at the beginning of the waveguide is

converted by a coil into an electrical signal. The travel time

of the wave is used to calculate the position. Depending

on the version, this information is made available as a

voltage or current output with a rising or falling gradient.

3

Construction and function

BTL7…-SR32

BTL7…-SR115 BTL7… cable

Mounting

surface

1)

Unusable area

2)

Not included in scope of delivery

Damping zone

Magnet

1)

Nominal length =

Measuring range

2)

1)

6 holes to fasten

the transducer

BTL7-A/C/E/G5 __ -M ____ -K(8)-SR32/SR115/___

Micropulse Transducer - Rod Style

Loading...

Loading...